Batch carrying device for glass beakers

A handling device and batch technology, which is applied in the field of glass beaker batch handling devices, can solve the problems of reducing the safety of the box-type handling device, dropping the box-type handling device to the ground, reducing the yield rate of glass beakers, etc., so as to avoid dropping to ground, avoid severe impact, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the purpose, solution and advantages of the technical solution of the present invention clearer, the technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings of specific embodiments of the present invention. Unless otherwise specified, terms used herein have their ordinary meanings in the art. The same reference numerals in the figures represent the same parts.

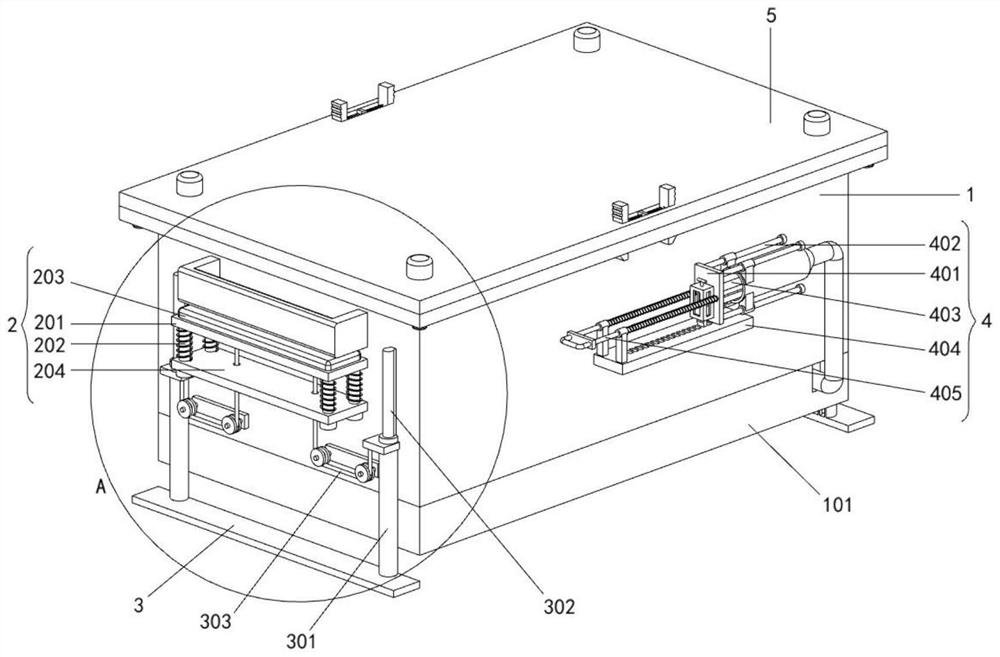

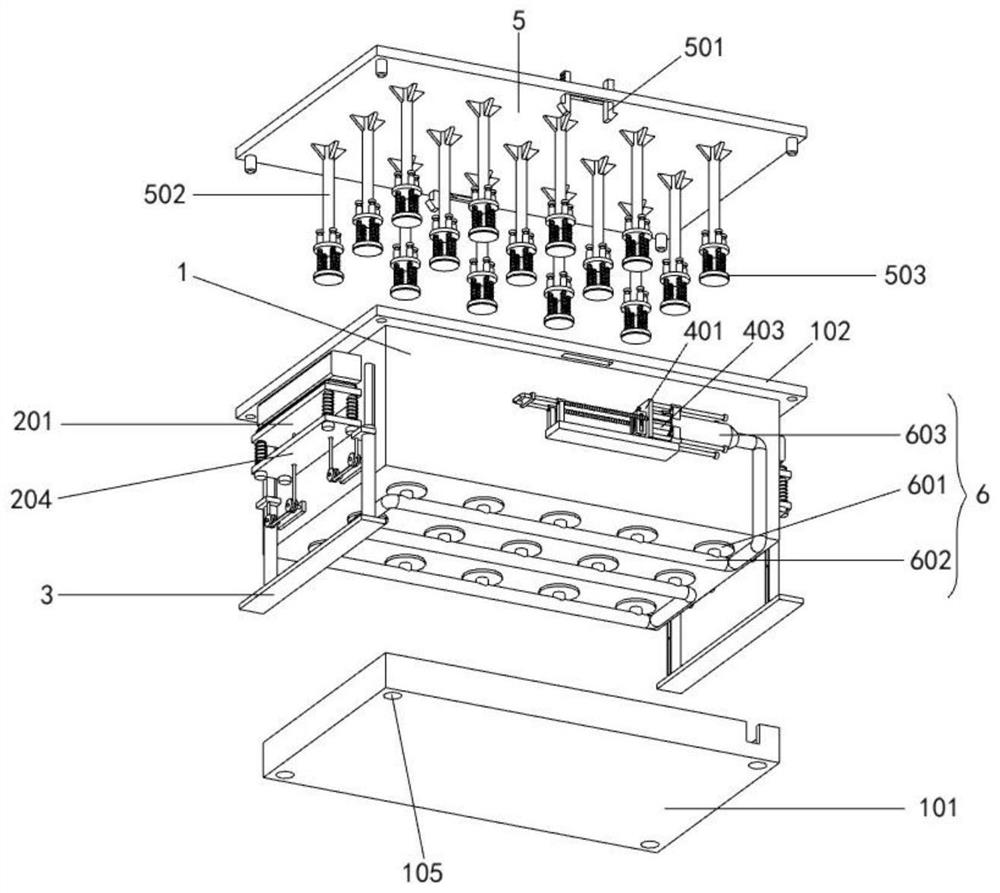

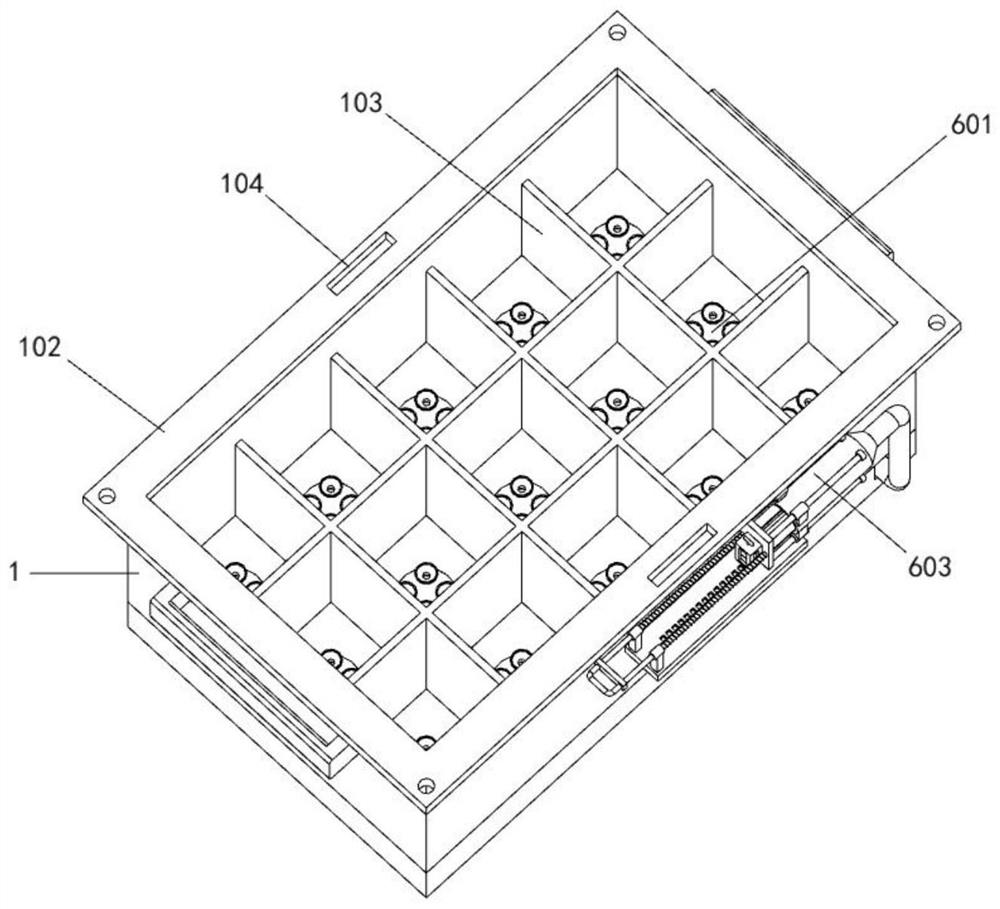

[0036] Such as Figure 1 to Figure 11 As shown, the batch handling device for glass beakers in the preferred embodiment of the present invention includes: a box body 1, a clamping mechanism 2 is provided on the left and right sides of the box body 1 at the lower part of the handle, and the lower parts of the left and right ends of the box body 1 are provided with A driving plate 3 is used to drive the clamping plate 201 to move downward. The front end of the box body 1 is provided with a negative pressure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com