Wood chip briquetting device for wood product production

A technology of wood products and chipped wood, which is applied in the field of chipped wood briquetting devices for wood product production, which can solve the problems of inconvenient extrusion of chipped wood raw materials, dust easily floating into the air, etc., and achieve the effect of avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

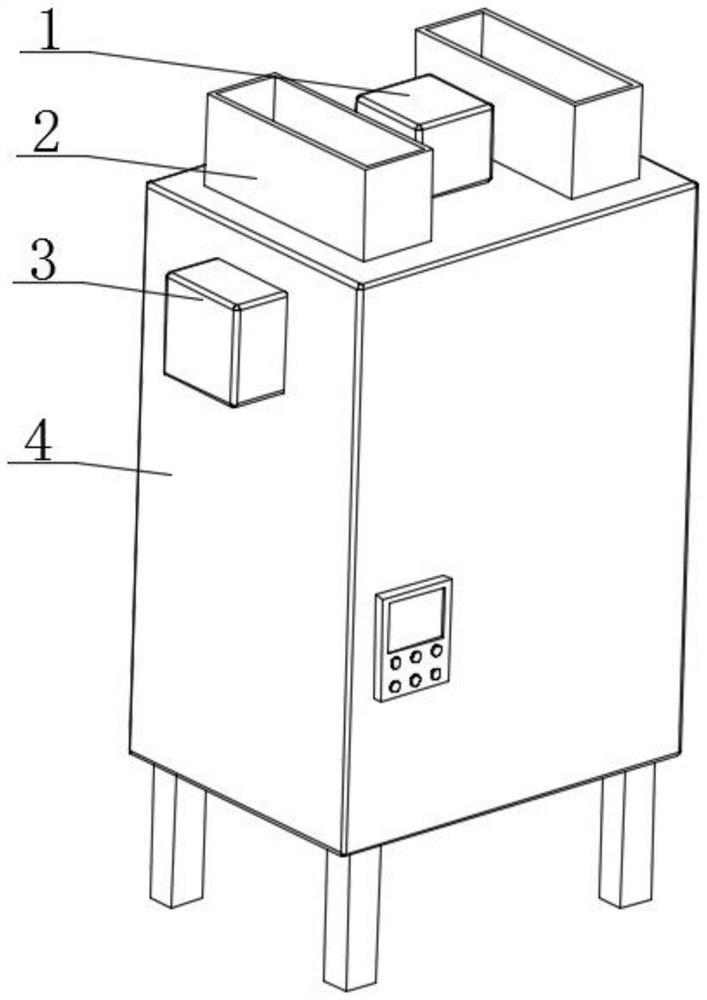

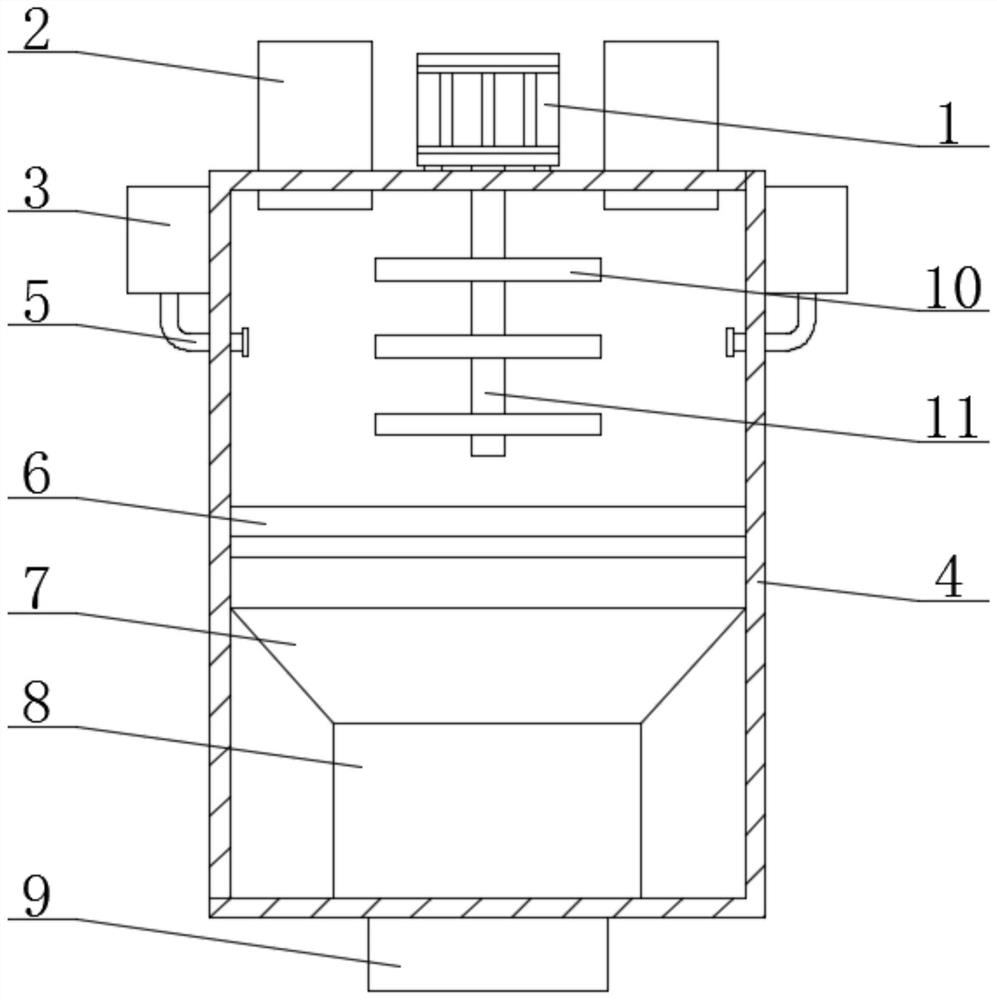

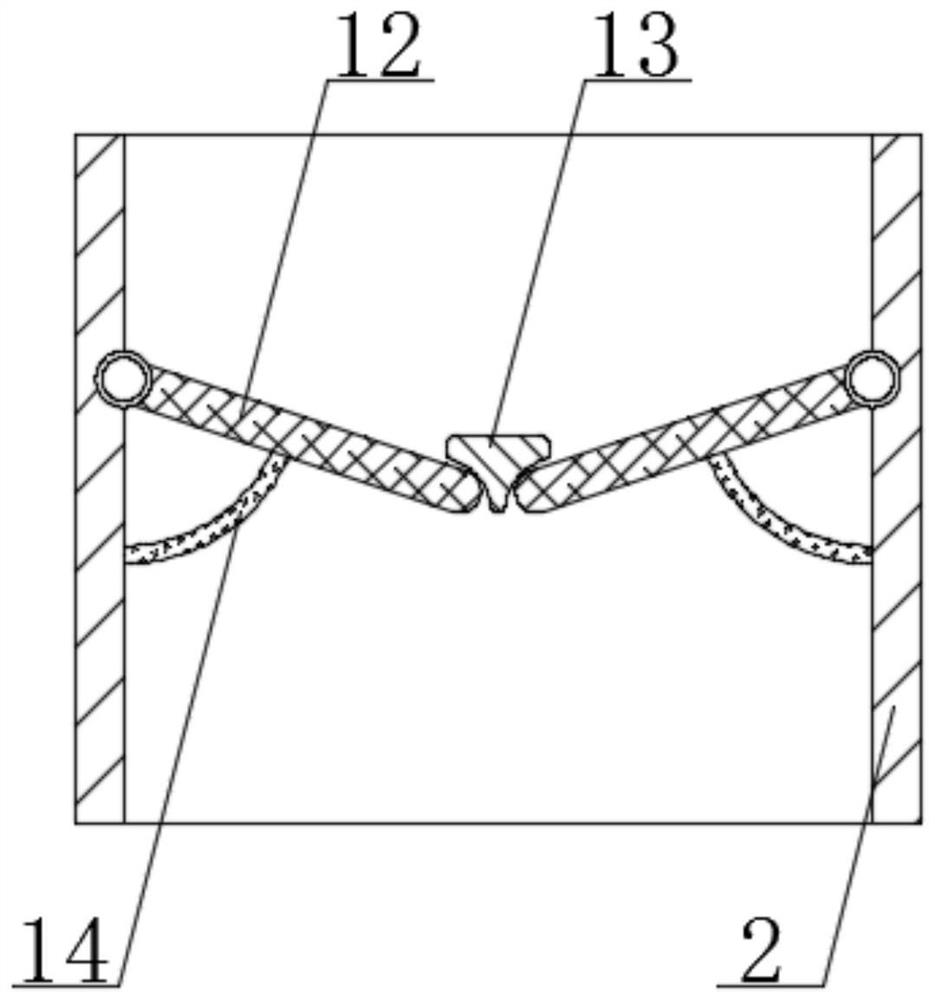

[0036] Such as Figure 1-6 As shown, the present invention provides a wood chip briquetting device for wood product production, comprising a drive motor 1, a feed hopper 2, a wood chip processing box 4, a discharge pipe 9, a mixing shaft 10 and a rotating shaft 11, and the chip wood The top center of the processing box 4 is fixedly equipped with a driving motor 1, and the driving end of the driving motor 1 is fixedly connected with a rotating shaft 11, and the bottom of the rotating shaft 11 runs through the inwall of the wood chip processing box 4 and extends to the bottom of the wood chip processing box 4. The inner wall, the outer wall of the rotating shaft 11 is fixedly connected with the mixing shaft 10, the top of the wood chip processing box 4 and the left and right sides of the drive motor 1 are provided with feed hoppers 2, and the bottom of each feed hopper 2 runs through the wood chip The inwall of processing box 4, the bottom of chip processing box 4 is provided wi...

Embodiment 2

[0041] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the top edge of the inner wall of the material guide frame 7 is fixedly connected with a mounting frame 22, and the bottom of the mounting frame 22 is fixedly connected with an electric telescopic rod 25 , the bottom of the electric telescopic rod 25 is fixedly connected with a pressing plate 26, the outer wall of the pressing plate 26 is slidingly connected with the inner wall of the briquetting box 8, and the electric telescopic rod 25 can push the pressing plate 26 to move downward, so that it is convenient to pass the pressing plate 26 to the crushed wood raw material. Squeeze, thereby can make wood chip raw material carry out compression molding, the inner wall of material guide frame 7 and be positioned at the below of installation frame 22 are fixedly installed vibrator 23, the outer wall of vibrator 23 is fixedly connected with guide bar 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com