Transportation device for production of oil pipe joint of automobile

A technology of oil pipe joints and transportation devices, which is applied in the direction of transportation and packaging, trolleys, motor vehicles, etc., which can solve the problems of being easily affected by inertia, heavy weight of joints, and high density of oil pipe joints, so as to avoid violent impact, facilitate operation, and facilitate Remove the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

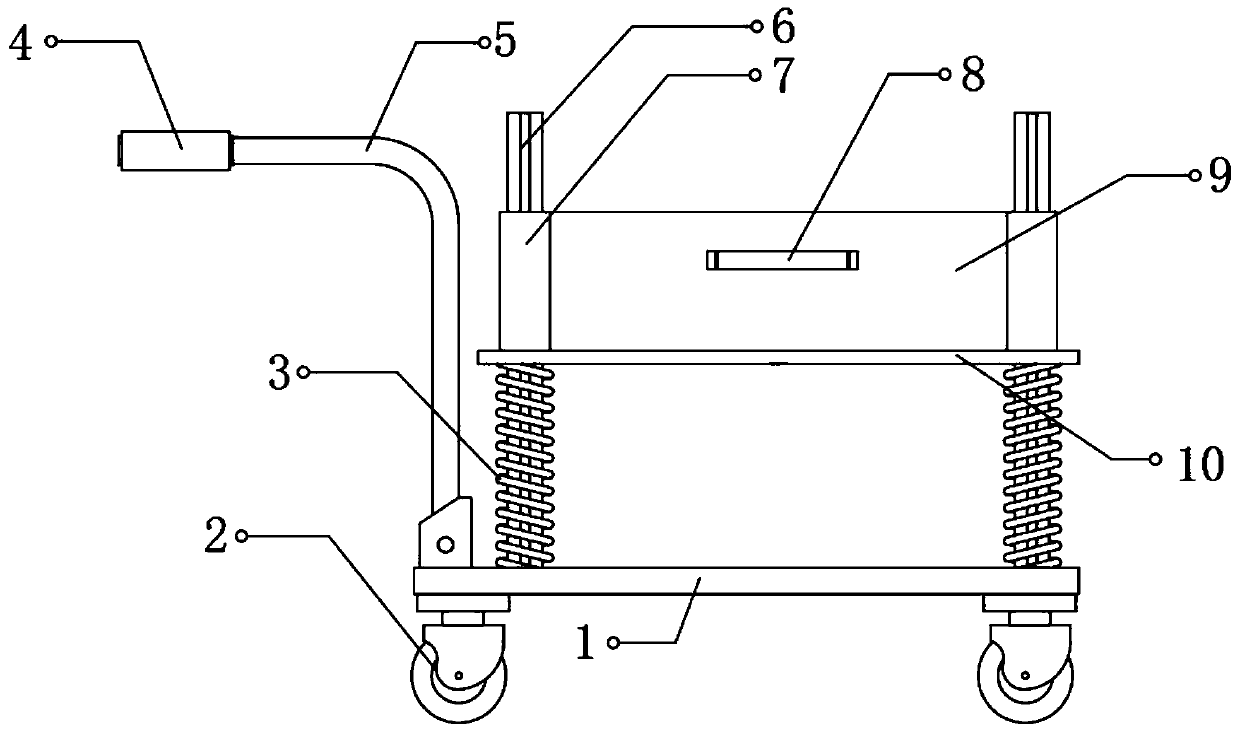

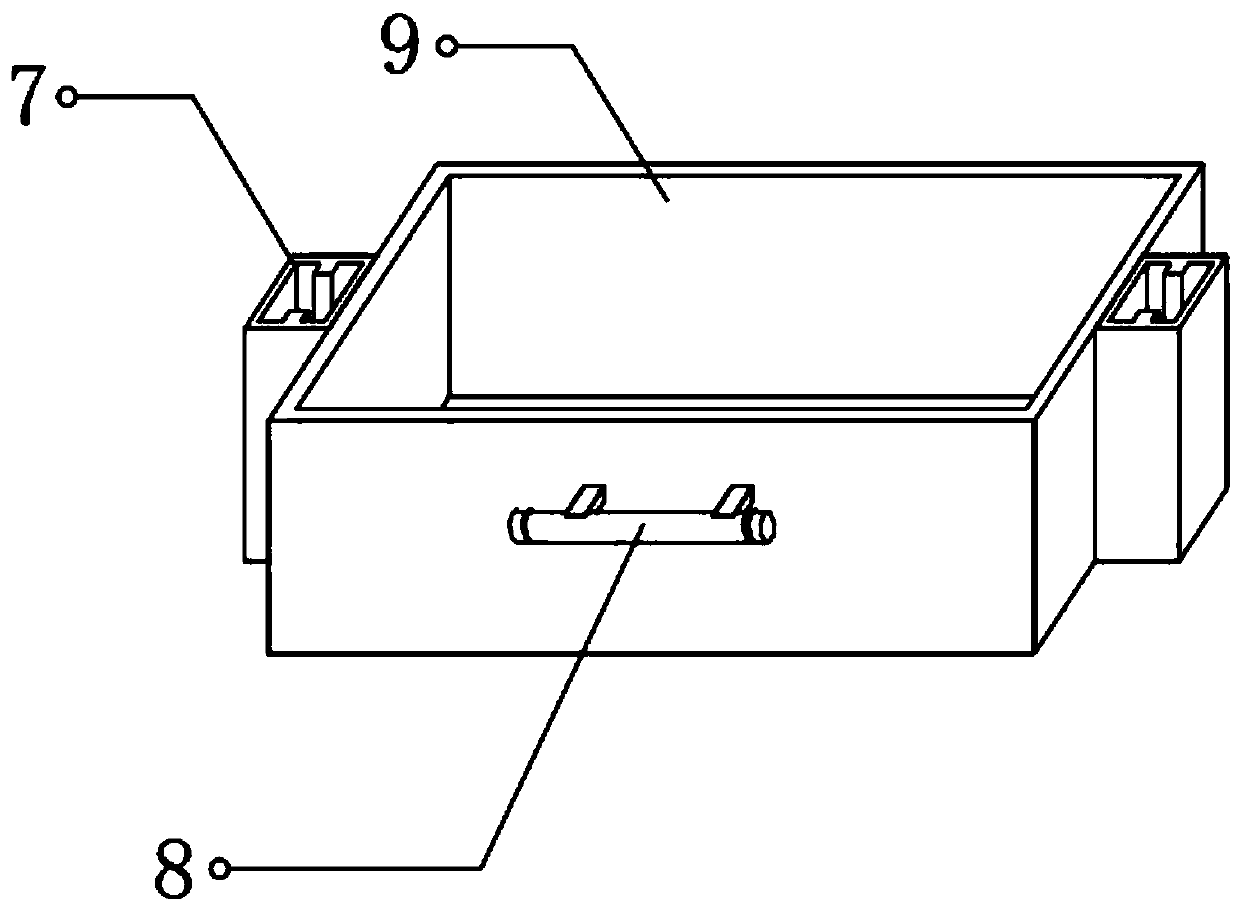

[0026] refer to Figure 1-2 , a transportation device for the production of automobile oil pipe joints, including a chassis 1, universal wheels 2 and push rods 5, four universal wheels 2 are fixedly connected to the four corners of the bottom of the chassis 1, and two push rods 5 are installed in parallel by bolts On one side of the top of the chassis 1, two slide rails 6 are fixedly connected to the top of the chassis 1, and the two slide rails 6 are plugged with the same sliding plate 10, and the two slide rails 6 are slidably connected to the same transport box 9, and The transport box 9 is located on the top of the sliding plate 10, and the oil pipe joint is placed in the transport box 9. The position of the transport box 9 is limited by the slide rail 6 to prevent the transport box 9 from falling under the action of inertia during transportation. At the same time, the slide rail 6 A plurality of transport boxes 9 can be plugged, so that the transport boxes 9 can be stacke...

Embodiment 2

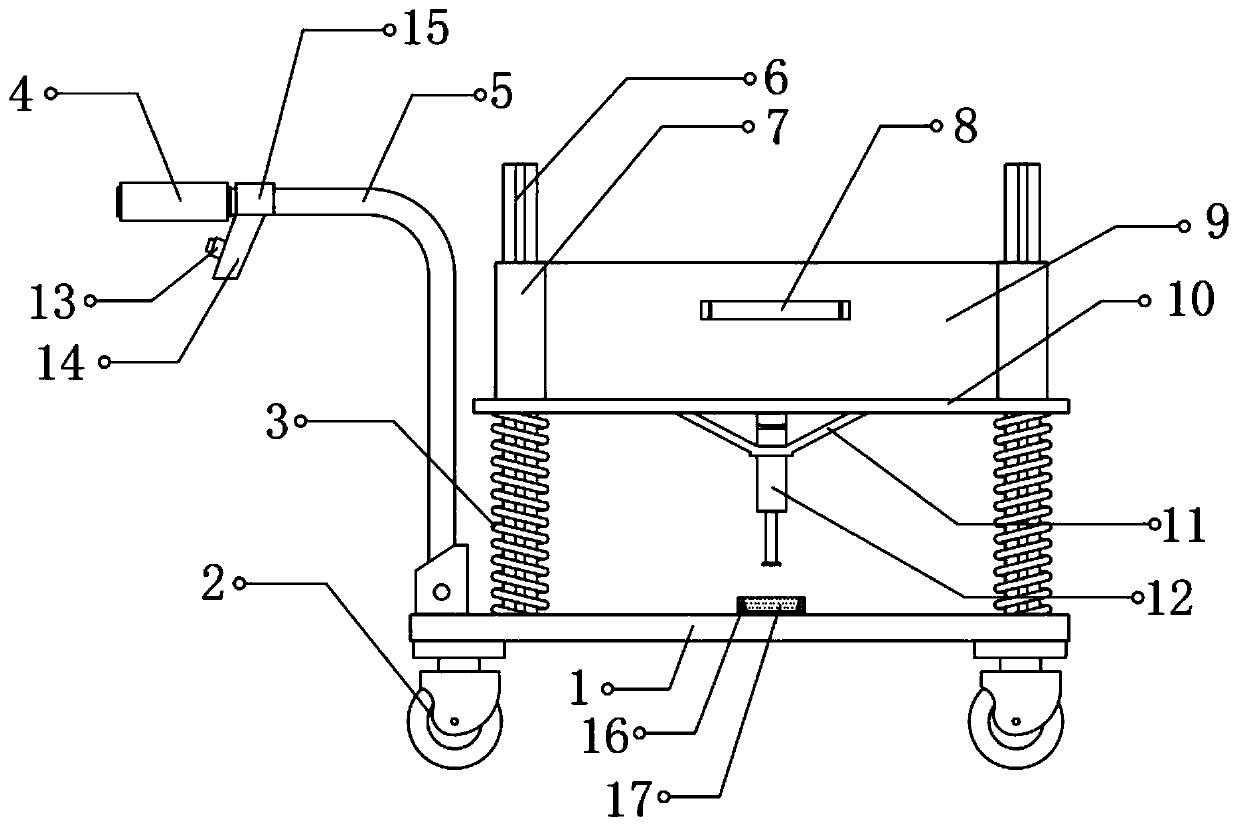

[0032] refer to image 3 , a transportation device for the production of automobile oil pipe joints. Compared with Embodiment 1, the middle position of the bottom of the sliding plate 10 is connected with an electric push rod 12 by bolts, and the outer wall of the middle part of the electric push rod 12 is fixedly connected with a support frame. 11. The top of the support frame 11 is welded to the bottom of the sliding plate 10 .

[0033] Wherein, a card slot 16 is welded at the middle position of the top of the chassis 1, and a rubber pad 17 is clipped inside the card slot 16, and the rubber pad 17 is located directly below the electric push rod 12. When a plurality of transport boxes are inserted on the slide rail 6 At 9 o'clock, the spring 3 is compressed by gravity, and the bottom of the electric push rod 12 is pressed on the top of the rubber pad 17, and the rubber pad 17 buffers the pressure.

[0034] Wherein, one end of two push rods 5 is all sleeved with handle 4, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com