Inertial cone energy-saving crusher

A crusher and cone technology, which is applied in the field of mineral crushers and inertia cone energy-saving crushers, can solve the problems of troublesome adjustment and effort, and achieve the effect of improving work efficiency and realizing selective crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

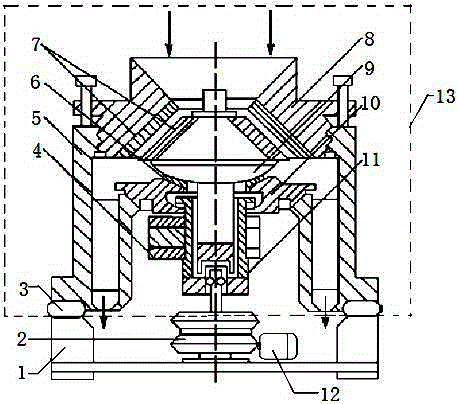

[0014] like figure 1 The shown inertia cone energy-saving crusher includes: chassis 1, belt drive 2, vibration isolation element 3, eccentric vibrator 4, shell 5, spherical support 6, liner 7, fixed cone 8, moving cone 9. Moving cone support 10, shaft sleeve 11 with eccentric exciter, motor 12 and body 13; the body 13 is located on the vibration isolation element 3, and the moving cone 9 is inserted into the eccentric The shaft sleeve 11 of the vibrator; the motor 12 is located in the chassis 1; the eccentric vibrator 4 is fixed on the shaft sleeve 11 with the eccentric vibrator.

[0015] The rotary motion of the motor 12 is transmitted to the eccentric vibrator 4 fixed on the shaft sleeve 11 with the eccentric vibrator through the belt drive 2 .

[0016] When the eccentric vibrator 4 rotates at a high speed, an inertial force is generated, so that the moving cone performs a pendulum motion around the center of the sphere supported by the spherical surface.

[0017] The work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com