An automatic assembly and disassembly screw machine for cnc fixture

A screw machine, assembly and disassembly technology, applied in manufacturing tools, metal processing equipment, metal processing, etc., can solve the problems of low work efficiency, large investment of human resources, increase of labor costs, etc., to reduce labor intensity and production costs , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention. The present invention will be described in detail below in conjunction with the accompanying drawings.

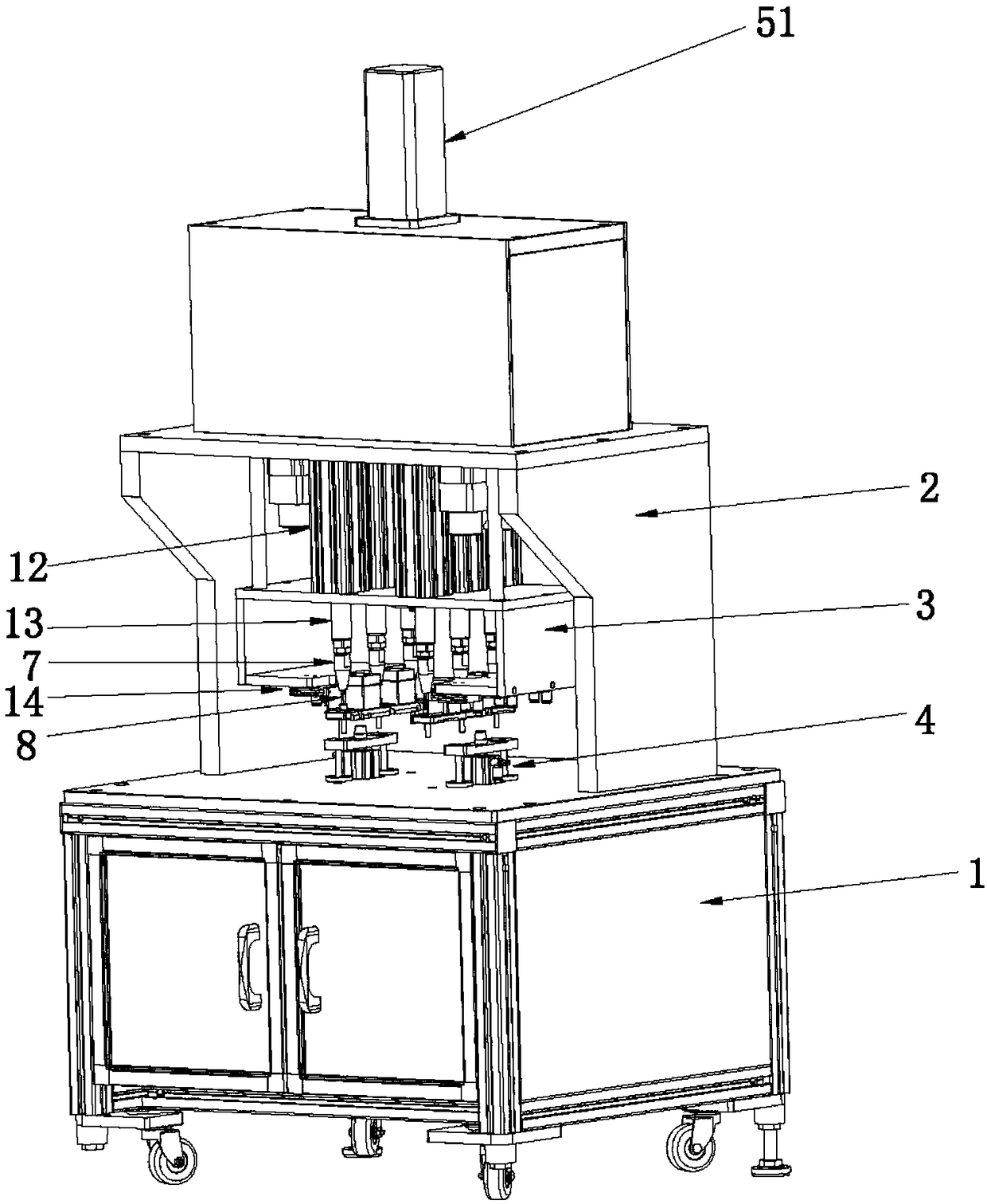

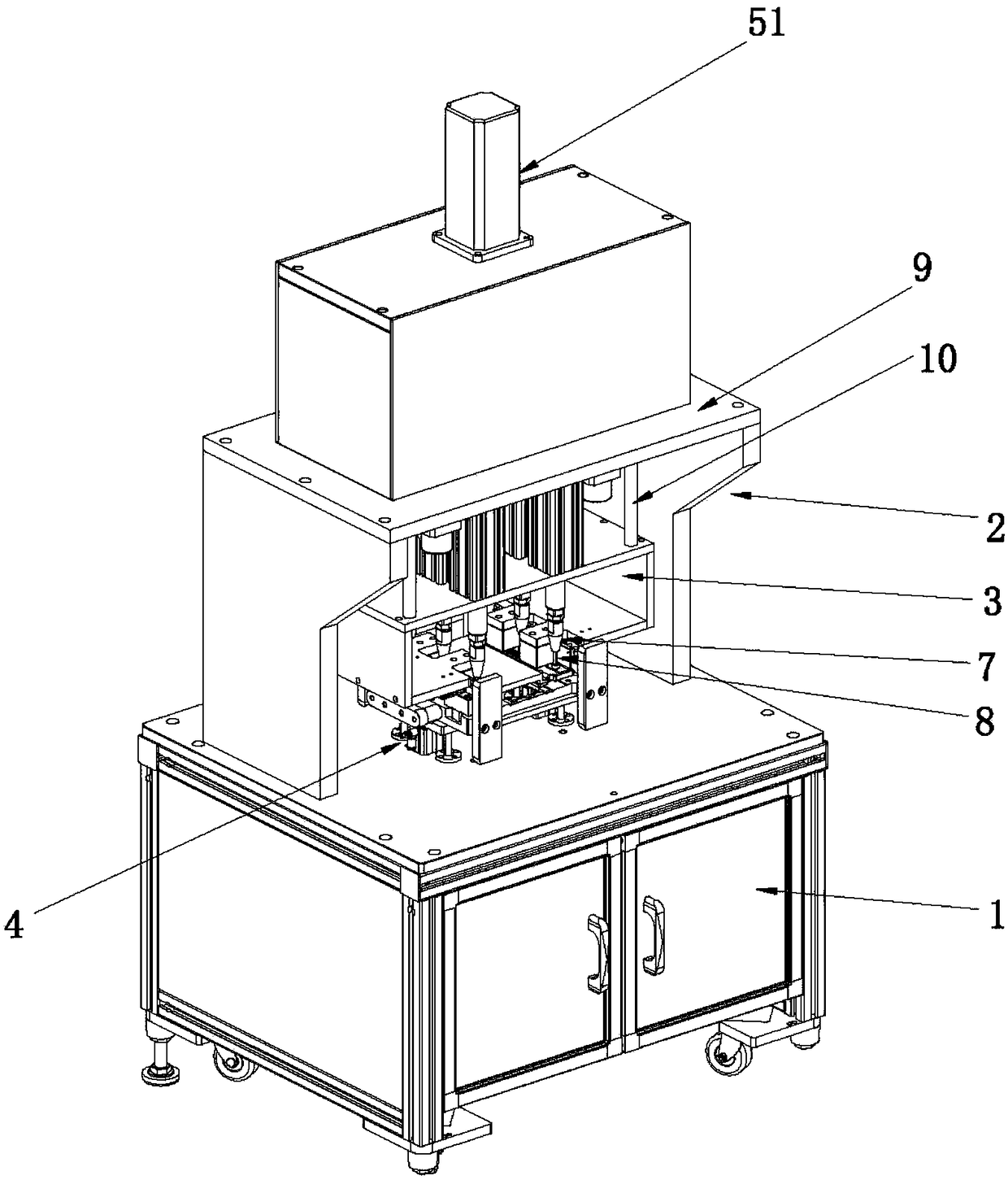

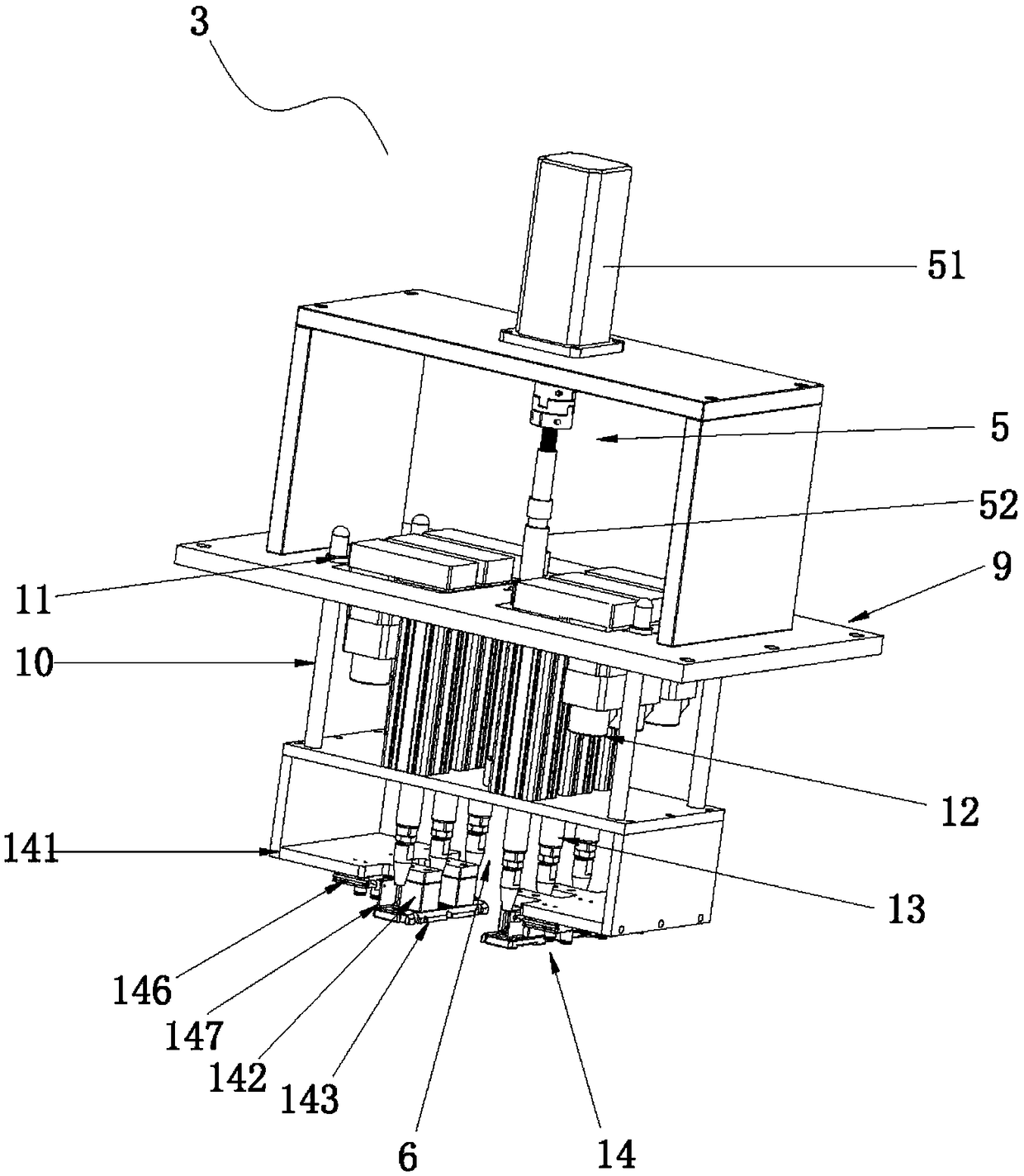

[0033] A screw machine for automatic assembly and disassembly of CNC fixtures provided by the present invention includes a cabinet 1 and a support frame 2 fixed above the cabinet 1, a screw assembly and disassembly mechanism 3 is installed on the support frame 2, and the cabinet 1 The upper end surface of the screw assembly and disassembly mechanism 3 is provided with a fixture positioning structure 4 corresponding to the screw assembly and disassembly mechanism 3 and used to position and place the CNC fixture. The screw assembly and disassembly mechanism 3 includes a vertical lift assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com