Machining fixture for transformer clamp tape limb plate and use method of machining fixture

A transformer clamping and machining technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

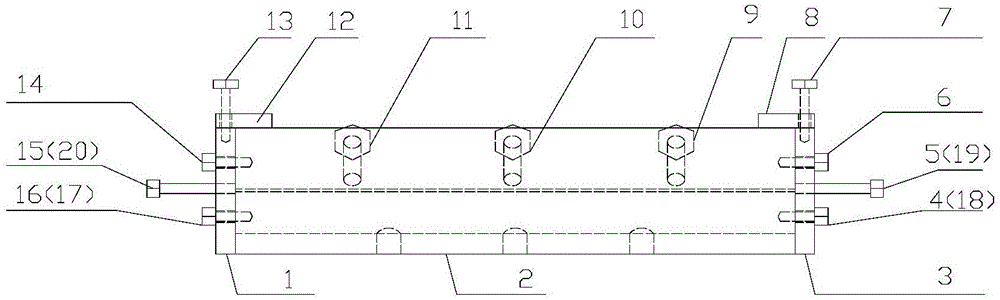

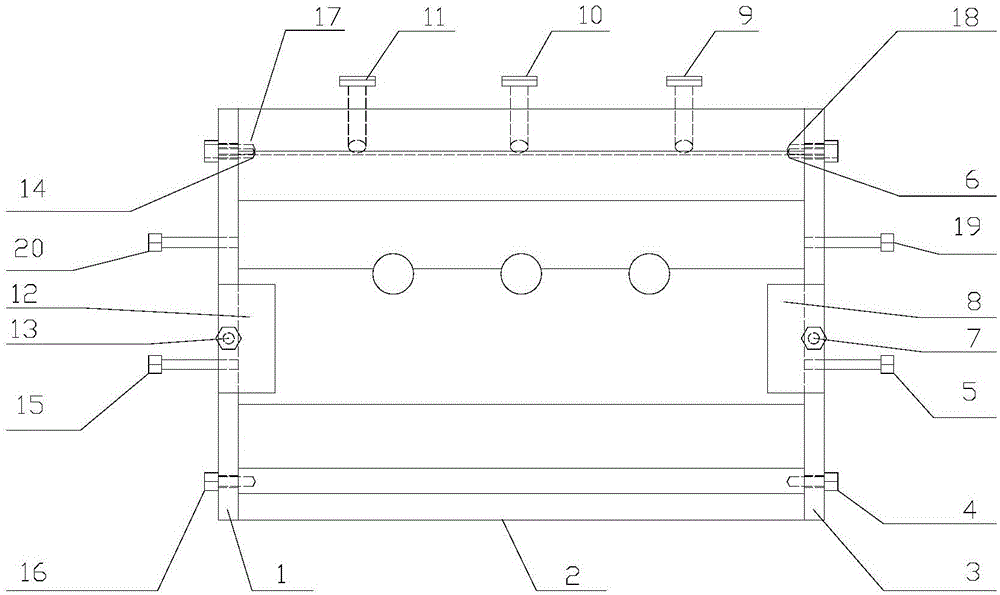

[0034] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

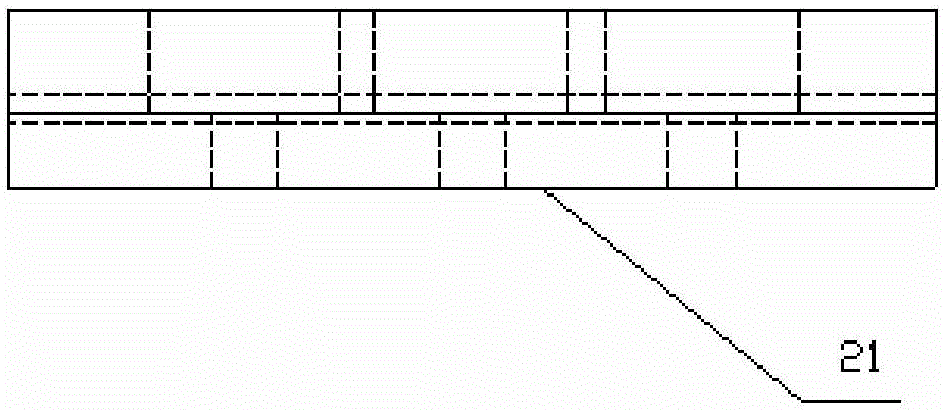

[0035] The clamping tool for the mechanical processing of the transformer clip pull belt limb plate of the present invention has a positioning plate 2, two side plates, two pressure plates and a plurality of fasteners, wherein the two side plates are respectively connected to the two ends of the positioning plate to form a The fastening tool frame that can hold the workpiece, the workpiece is clamped in the fastening tool frame by a plurality of fasteners; the shape of the upper end surface of the positioning plate 2 matches the shape of the bottom surface of the workpiece 21, and the hole on the positioning plate 2 matches the hole on the workpiece 21 The holes are concentric holes; two upper pressing plates are respectively connected to the upper ends of the two side plates in a horizontally rotatable manner.

[0036] Such as figure 1 , 2 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com