Spring-loaded tensioning device for speed limiting steel wire rope

A technology for tensioning devices and steel wire ropes, applied in the field of tensioning devices, can solve problems such as inability to adjust sensitively and provide insufficient and accurate guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

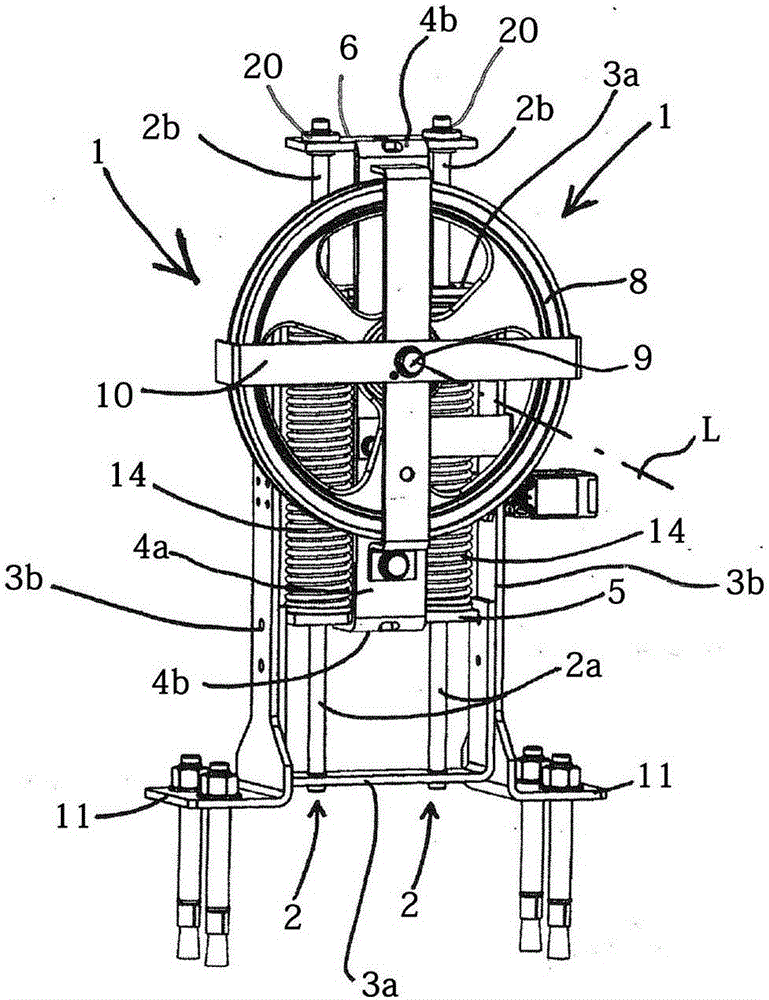

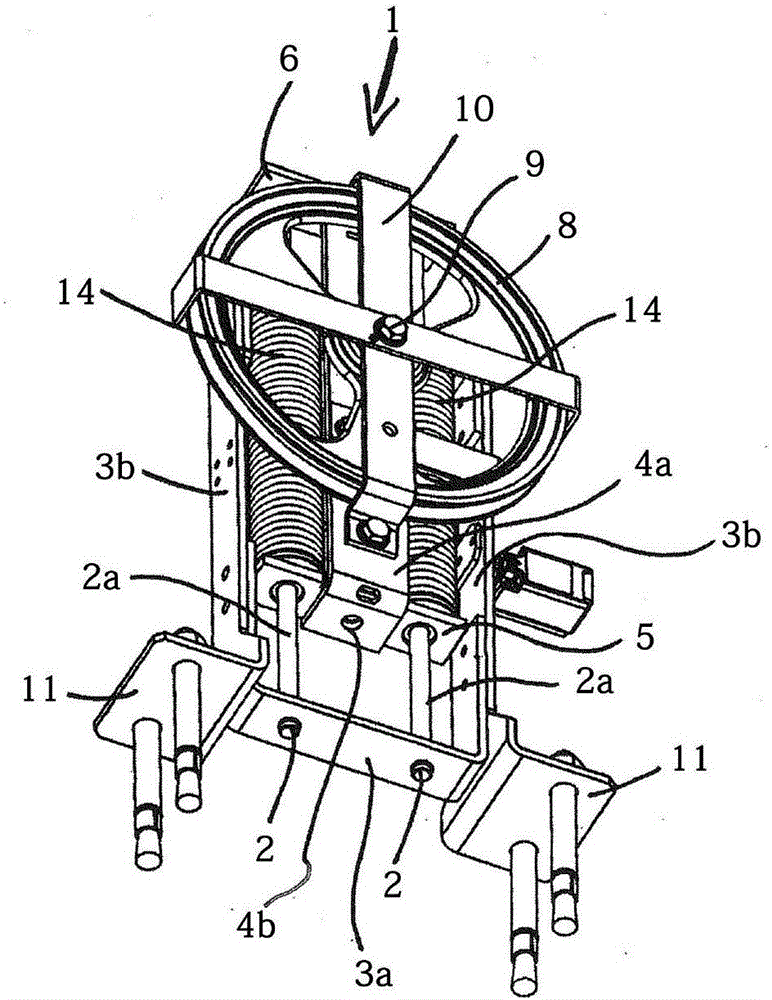

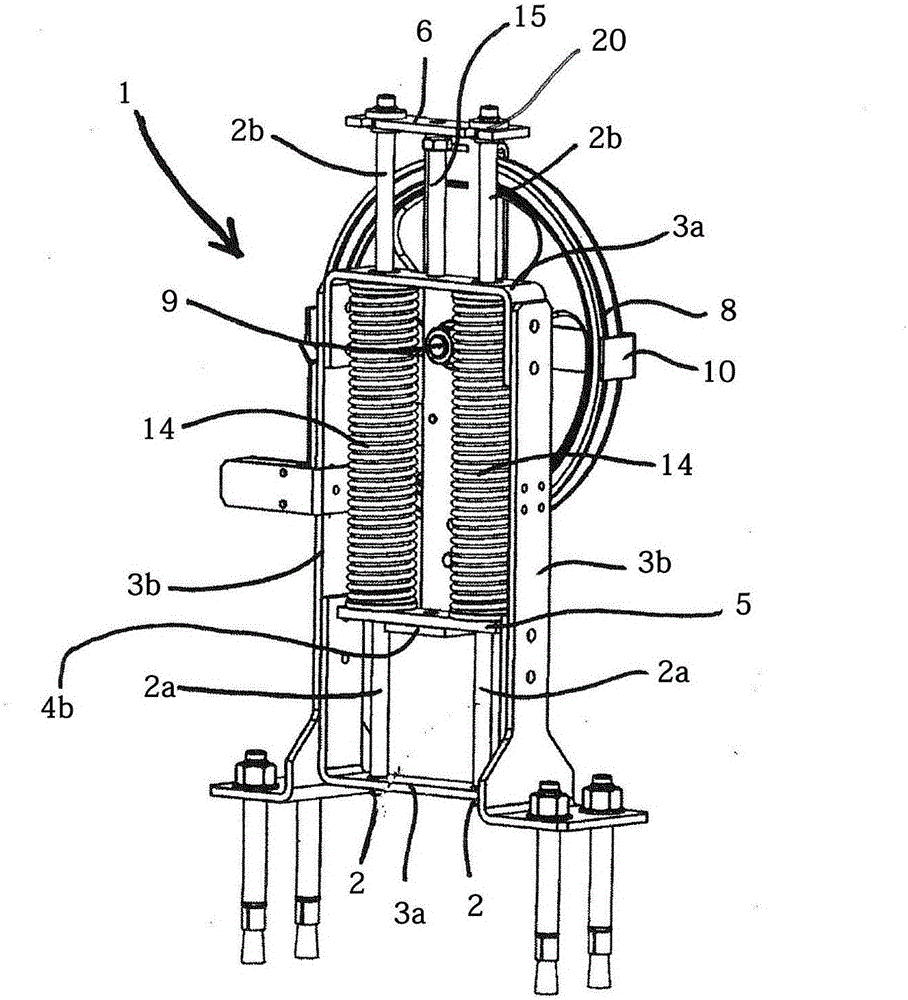

[0038] The core part of the tensioner is the main frame, which consists of two horizontal sections 3a and two vertical sections 3b, see figure 2 . This frame, which is usually completely closed on all sides, actually constitutes an imaginary cuboid which is open on its two large faces. The main frame is ideally made of flat steel, which is bent by 90° where necessary. The main frame forms an annular cage for the spring element 14 .

[0039] At least two guide posts 2 are fixed on the lower horizontal part 3a of the main frame, preferably with the help of threads or, less preferably, with the help of corresponding welds or spots. These two guide columns traverse the inner space of the main frame 3a, 3b, pass through two openings in the upper horizontal part 3a of the main frame and protrude from the main frame above the main frame, see image 3 and Figure 4 . In this way, the guide post 2 constitutes a first guide post part 2a in the area enclosed by the main frame and a...

no. 2 example

[0051] The second embodiment differs from the first embodiment only in that it is not intended to be fitted on the bottom of the stairwell, but is preferably fixed on the lower end of the guide rail with the aid of the guide rail bracket, ie for wall mounting. Based on this, the statements regarding the first embodiment also apply to the second embodiment, so that reference can be made thereto.

[0052] to combine Figure 6 It can be clearly seen that the feet 11 are omitted in this exemplary embodiment. Instead, the rail holder 12 is fixed, preferably screwed, to the main frame 3a, 3b. The rail holder preferably has elongated holes or single holes, which are arranged closely one after the other and intersect each other laterally, in order to be able to be fastened with the aid of various rail fixing clips for wall mounting of the rail.

[0053] Additionally, combined with Figure 6 It can also be clearly seen that another characteristic, that is, it can also be realized in...

no. 3 example

[0057] Figure 7 and Figure 8 A third embodiment is shown. The third embodiment corresponds almost completely to the first embodiment, so the expressions related to the first embodiment are also used for the third embodiment, as long as no difference is obtained from the following differences.

[0058] The third exemplary embodiment differs from the first exemplary embodiment in that each spring element 14 (here also designed as a helical compression spring) is threaded on a guide tube 19 . Each guide tube 19 itself is threaded on the guide post 2 . The individual guide tubes 19 are preferably dimensioned in such a way that they completely traverse the area enclosed by the main frame 3a, 3b and preferably rest against the upper and lower vertical parts 3b of the main frame, preferably correspondingly with centering bushes 21 provided. The outer diameter of the guide tube 19 is preferably 1 mm to 2 mm smaller in size than the inner diameter of the spring element 14 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com