Efficient oil water separation device

An oil-water separation device and high-efficiency technology, applied in the fields of hydrocarbon oil dehydration/demulsification, petroleum industry, processing of hydrocarbon oil, etc. The effect of high degree of automation and strong adaptability to low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

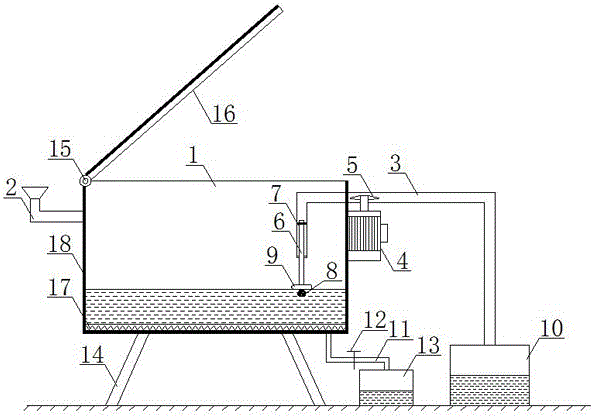

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] as attached figure 1 As shown, a high-efficiency oil-water separation device of the present invention includes a box body 1, an input pipe 2, an oil suction pipe 3, a motor 4, an oil discharge impeller 5, a connecting pipe 6, a slider 7, a filter head 8, a floating plate 9, Oil storage tank 10, sewage pipe 11, control valve 12, collection box 13, legs 14, rotating shaft 15, cover 16, heating device 17 and insulation layer 18, wherein the box body 1 has an open upper mouth; wherein the box body 1 The side walls of the tank are respectively provided with an input pipe 2 and an oil suction pipe 3; wherein the oil suction pipe 3 is equipped with an oil discharge impeller 5; wherein the oil discharge impeller 5 is connected with the drive shaft of the motor 4; wherein the connecting pipe 6 is movably connected by a slider 7 Inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com