Method of testing depth of tiny hole

A hole and depth technology, applied in the field of testing the depth of tiny holes, can solve the problems of limited image magnification, unsuitable for depth measurement of tiny holes, unable to measure the depth of tiny holes, etc., and achieve the effect of clear display.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] 1. Cut out a laser-ablated spotted steel plate suitable for the size of the scanning electron microscope, and polish and dry the surface of the steel plate;

[0021] 2. Use conductive glue to stick the sample on the sample stage of the scanning electron microscope, and then put the sample stage with the sample on the stage;

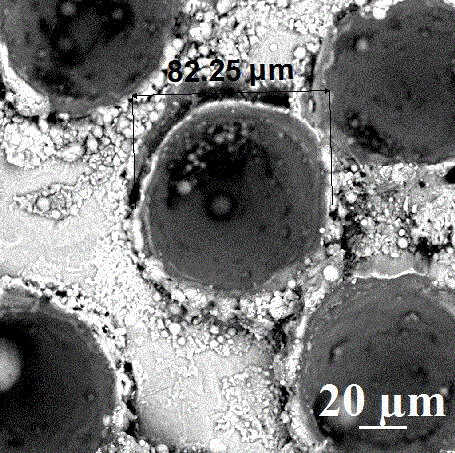

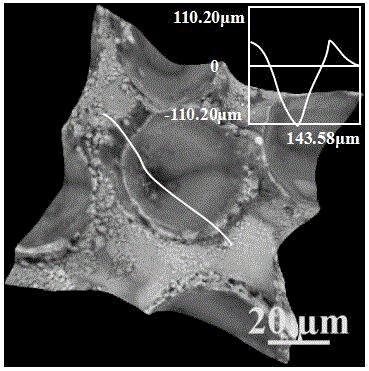

[0022] 3. Adjust the parameters of the scanning electron microscope, and use the electronic image of the scanning electron microscope to take the surface topography of the holes as shown in the attached photo. figure 1 shown, and then use the 3D surface reconstruction function to obtain the attached figure 2 The clear 3D surface reconstruction picture shown;

[0023] 4. According to the height difference between the hole surface and the bottom position on the three-dimensional surface reconstruction image, the depth value of the hole can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com