Method used for predicting creep life of heat-resisting alloy

A technology of creep life and heat-resistant alloys, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., to achieve the effect of low error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This example is a method for predicting the creep life of 403Nb steel at 600°C and 180MPa. Proceed as follows:

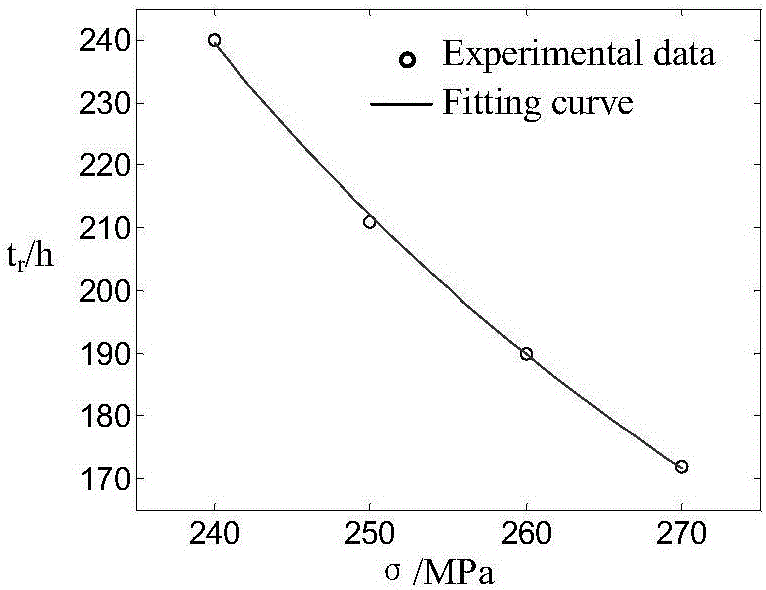

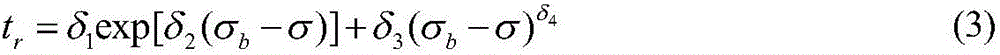

[0058] First, according to the "GB / T4338-2006 High Temperature Tensile Test Method for Metal Materials", a sheet-shaped "I"-shaped sample with a cross-section of 2.5mm×4.5mm and a gauge length of 14mm was used to measure the tensile strength σ of 403Nb steel at 600°C. b According to the "GB / T2039-2012 Metal Material Uniaxial Tensile Creep Test Method", a single-head testing machine is used to measure the tensile strength of 403Nb steel under 600°C, 240MPa, 250MPa, 260MPa, and 270MPa stresses. Tensile creep life, respectively: 240h, 211h, 190h, 170h; through the prediction model of creep life The least square method is used to fit the above creep test data to determine the parameter δ i (i=1,2,3,4) value: 0.0030,0.0260,0.0291,1.4170; In the formula: t r is the creep life, σ is the stress. The average fit error was 0.021%. Such as figure 1 Shown are the ...

Embodiment 2

[0063] This example is a method for predicting the creep life of HP40 alloy at 900°C and 35MPa. Proceed as follows:

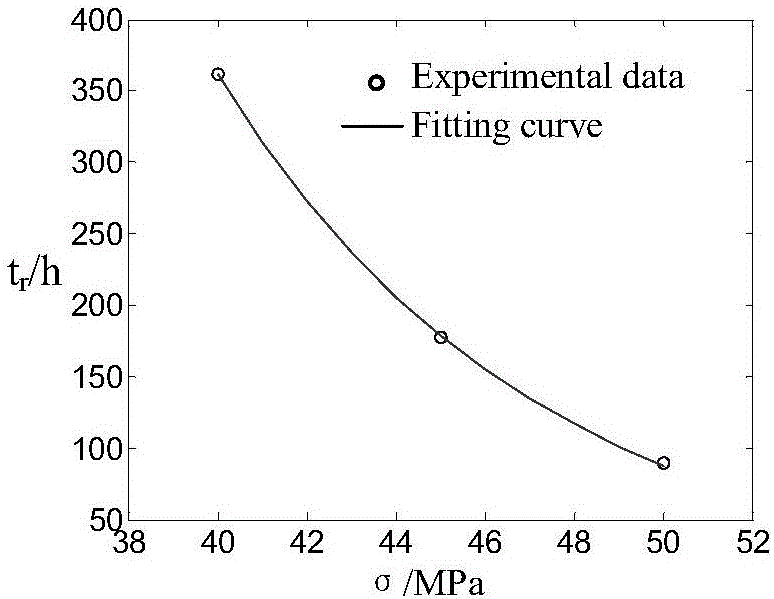

[0064] First, according to the "GB / T4338-2006 High Temperature Tensile Test Method for Metal Materials", a sheet-shaped "I"-shaped sample with a cross-section of 2.5mm×4.5mm and a gauge length of 14mm was used to test the tensile fracture of the HP40 alloy at 900°C Intensity σ b It is 200MPa; according to "GB / T2039-2012 Metal Material Uniaxial Tensile Creep Test Method", a single-head testing machine is used, and the sample specification is the same as above, to measure the tensile creep of the alloy at 900°C, 40MPa, 45MPa, 50MPa stress The service life is respectively: 362h, 177h, 89h; through the prediction model of creep life The least square method is used to fit the above creep test data to determine the parameter δ i (i=1, 2, 3, 4) values: 5.9255e-004, 0.0854, -0.0183, 1.7774; as figure 2 Shown are the fitting curves of HP40 alloy 900°C and differen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com