'Yi' shape insulating embraced mast for on-load replacement of high pressure cascade fuse

A drop-out fuse and load-carrying technology, which is applied in the direction of electrical components, circuits, emergency protection devices, etc., can solve problems such as grounding faults, high psychological pressure on personnel, and electric shock injuries, so as to improve replacement speed and replacement efficiency, and improve operation Safety, the effect of reducing psychological stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

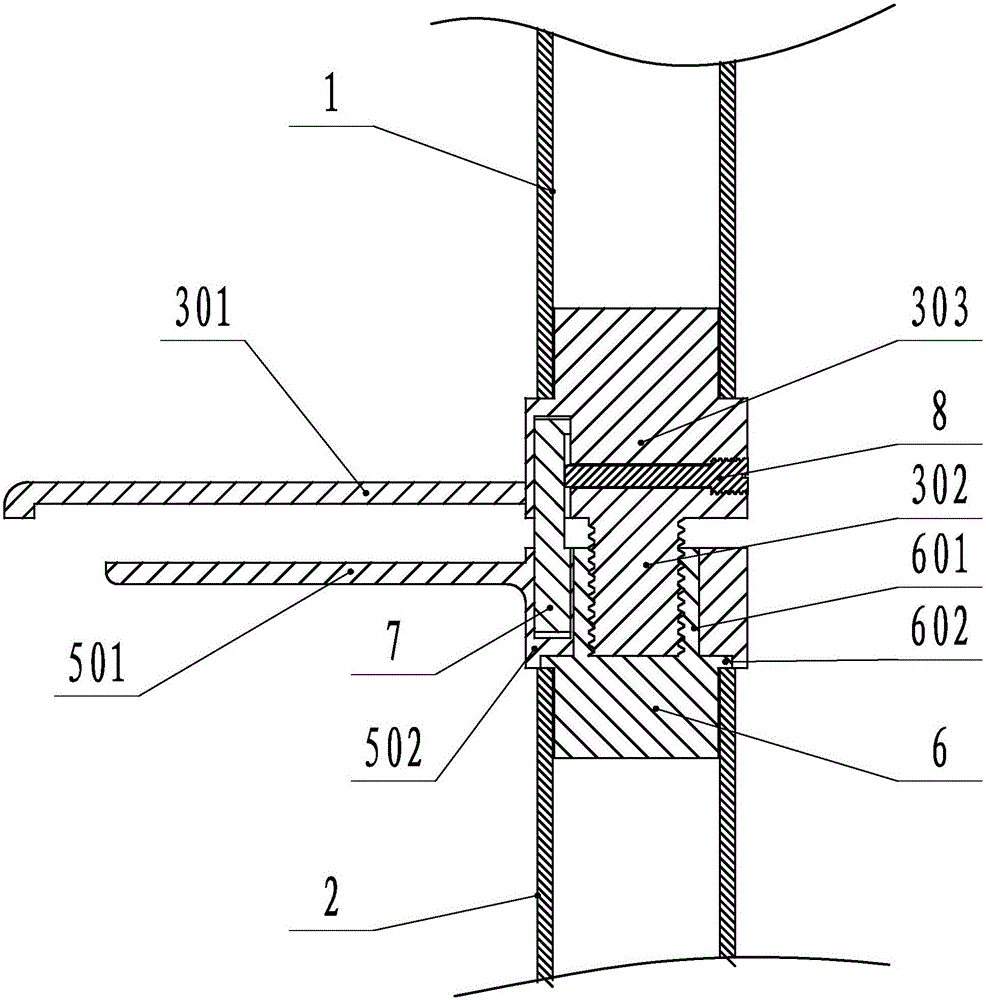

[0030] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

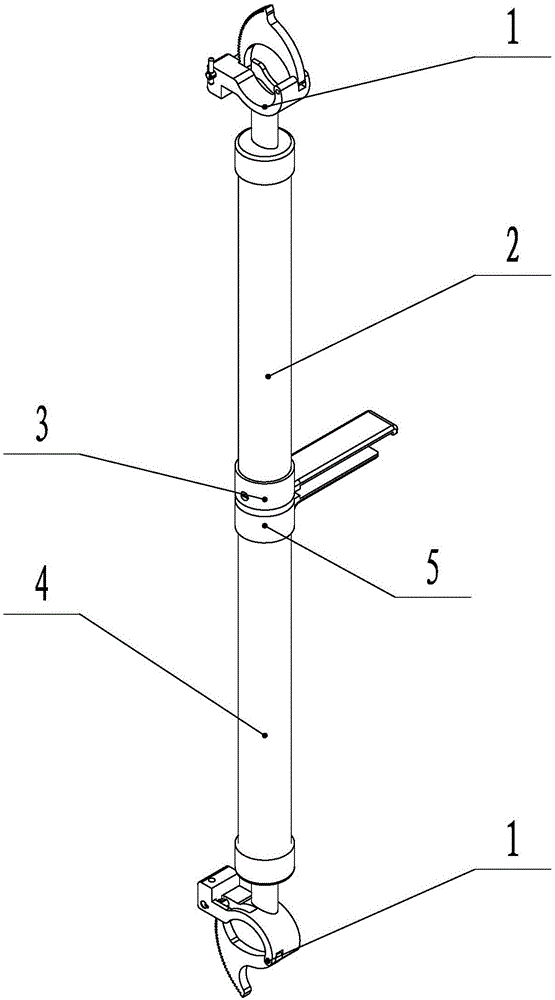

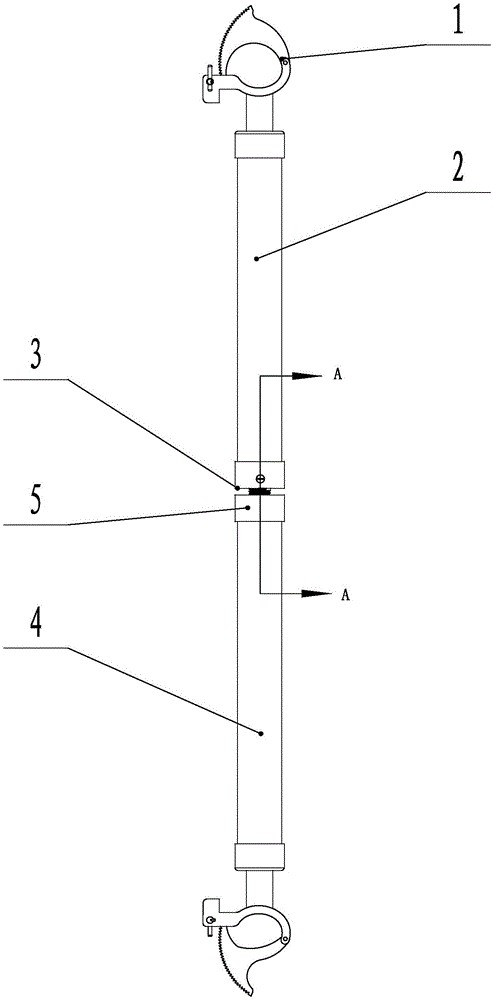

[0031] Such as Figure 1-5 As shown, the one-word insulation holding rod for replacing the high-voltage drop-out fuse with load includes the insulation rod and the wire locker 1 at the end of the insulation rod. The insulation rod includes the upper rod 2, the lower rod 4, the upper rod 2 and the lower end. The middle of the two is connected by a connecting piece, and the connecting piece includes a clamping piece for fixing the insulating rod on the cross arm, an elastic member for realizing the loosening operation of the clamping piece, preventing the upper rod 2 and 2 when the clamping piece is loosened The limiting member for disengagement of the lower rod 4; the thread locker 1 is arranged on the upper end of the upper rod 2 and the lower end of the lower rod 4.

[0032] In order to realize the operation of clamping and looseni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com