Method for applying heat conducting patches to a material web

A technology of heat conduction and heat conduction elements, which is applied in the direction of printing, printing, inhalers, etc. for the production of special varieties of printed matter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

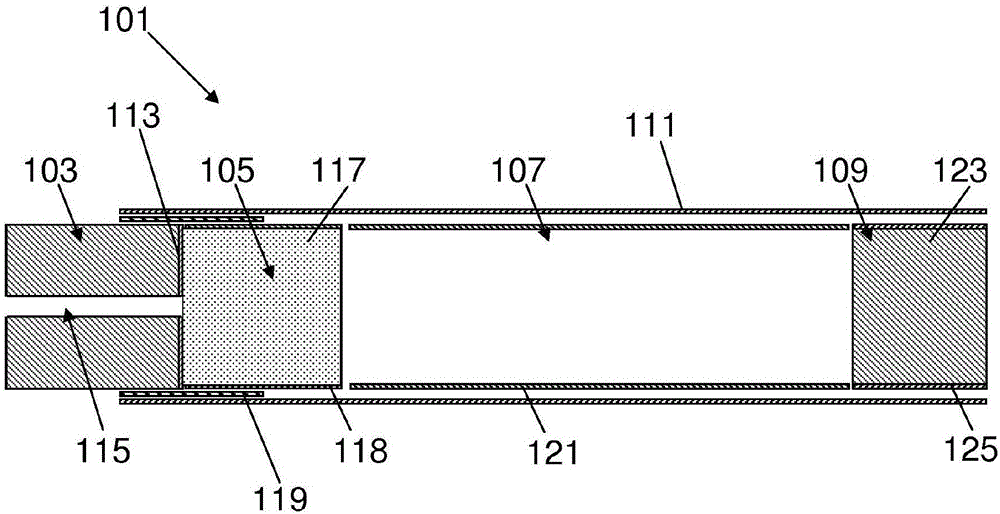

[0137] figure 1 A first example of a smoking article comprising a heat conducting element made according to the invention is shown. The smoking article 101 comprises a combustible carbonaceous heat source 103 , an aerosol-forming substrate 105 , an elongated expansion chamber 107 and a mouthpiece 109 aligned contiguously on one axis. The combustible heat source 103, aerosol-forming substrate 105, elongate expansion chamber 107 and mouthpiece 109 are overwrapped in an outer paper wrapper 111 of low-air permeability cigarette paper. Such as figure 1 As shown, a non-combustible, gas-resistant first barrier coating 113 is provided over substantially the entire rear surface of the combustible carbonaceous heat source 103 . In an alternative embodiment, a non-combustible, substantially gas-impermeable first barrier layer is provided in the form of a disc adjacent to the rear surface of the combustible carbonaceous heat source 103 and the front surface of the aerosol-forming substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com