Consumable cartridge for a plasma arc cutting system

A plasma arc, separation force technology, used in plasma, plasma welding equipment, manufacturing tools, etc., can solve the problem of inability to dissipate and conduct heat from the torch, significant manufacturing costs, and inability to maintain proper alignment and spacing of consumables And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

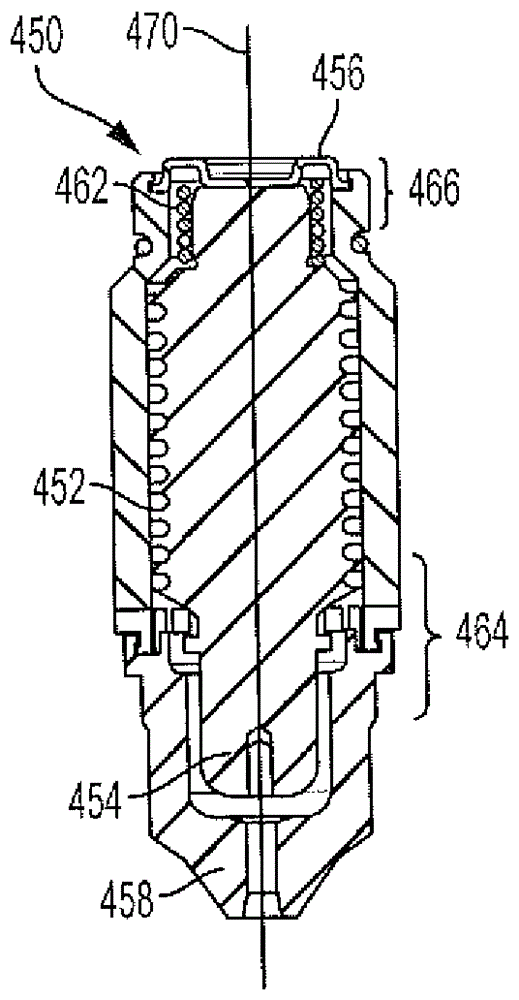

[0028] figure 1 is a cross-sectional schematic illustration of a cartridge 100 for a plasma arc cutting system according to an exemplary embodiment of the present invention. Cartridge 100 has a first end 104 , a second end 108 , and a generally hollow frame 112 having a first section 112A toward first end 104 and a second section toward second end 108 . 112B. Cartridge 100 also includes arc emitter 120 , arc retractor 124 , and resilient element 128 . Arc emitter 120 is located within frame 112 and is translatable relative to frame 112 . As shown, the arc retractor 124 forms part of the frame 112 (eg, at the second end 108 , but may be attached to the frame 112 in some embodiments). The resilient element 128 is in physical communication with the frame 112, such as in direct physical communication with the first section 112A. In some embodiments, resilient member 128 is a contact activated spring element secured to arc emitter 120 . Resilient element 128 may be configured ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap