Medical procedure simulator

A surgical simulator and medical technology, applied in the field of medical surgical simulators, can solve problems such as problems and achieve the effect of reducing demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

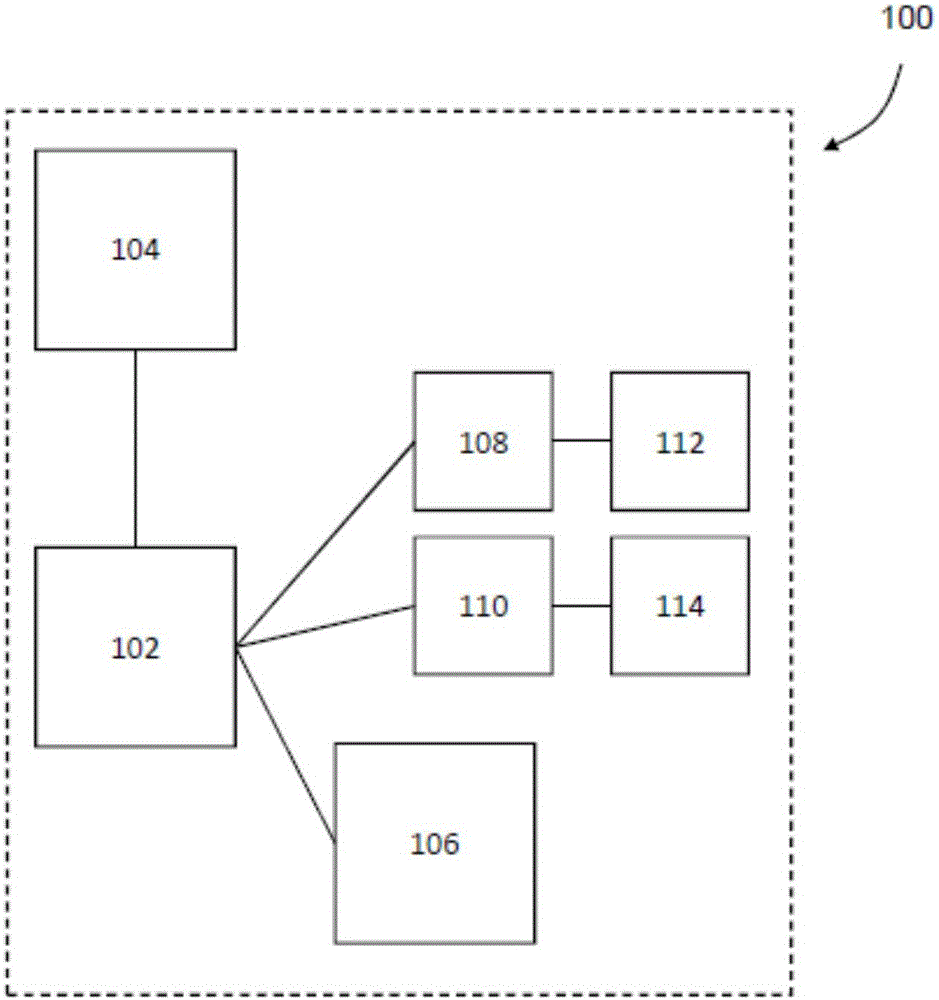

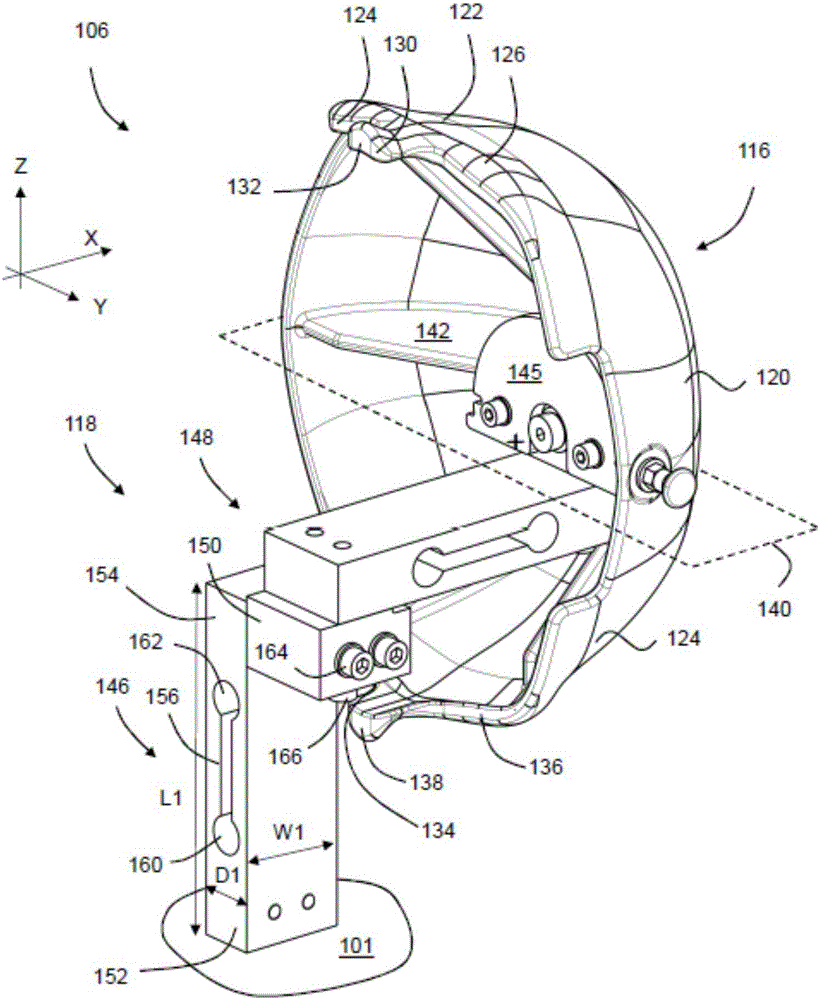

[0047] figure 1 is a schematic diagram of an ophthalmic surgery simulator 100 . The simulator 100 includes a computer 102 having memory and a processor. The processor is arranged to execute software stored in the memory, in particular software for simulating a medical procedure such as an ophthalmic operation. Computer 102 is connected to VDU 104 , stand 106 , first haptic system 108 and second haptic system 110 .

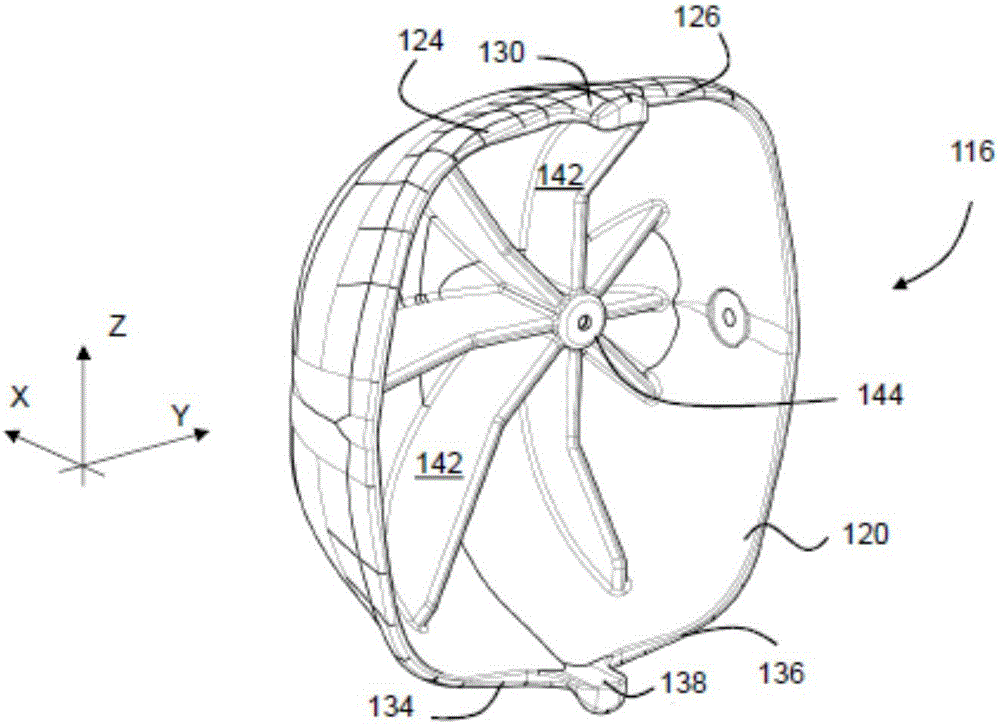

[0048] The VUD is configured with two separate outputs mounted behind respective eyepieces which are closer to the ophthalmic microscope.

[0049] Each haptic system 108, 110 includes first and second handpieces 112, 114, respectively. Haptic systems 108, 110 and handpieces 112, 114 will not be described in detail. Generally, the haptic systems 108, 110 are configured to monitor the position of the handpieces 112, 114, respectively, and provide force feedback. As the user operates the handpieces 112, 114, the computer 102 moves the virtual tool in the virtua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com