Control system special for industrial dust removing equipment and control method of control system

A technology of dust removal equipment and control system, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems that limit the fine development of industrial dust removal equipment, the large operation workload of dust removal equipment, and the large volume of electric control cabinets/boxes. and other problems, to achieve the effect of optimizing function and appearance, saving equipment space, and fully functional

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings.

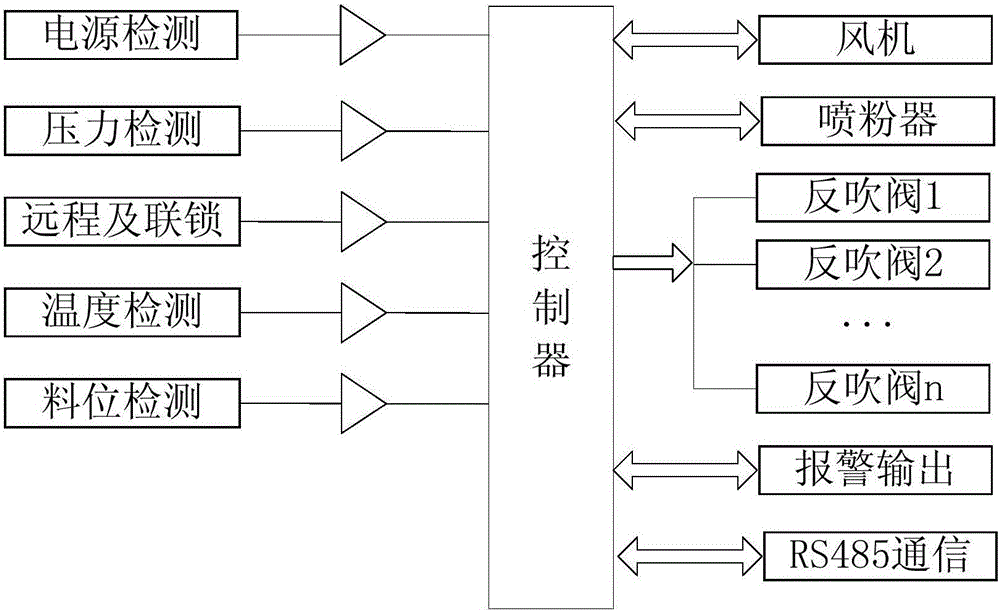

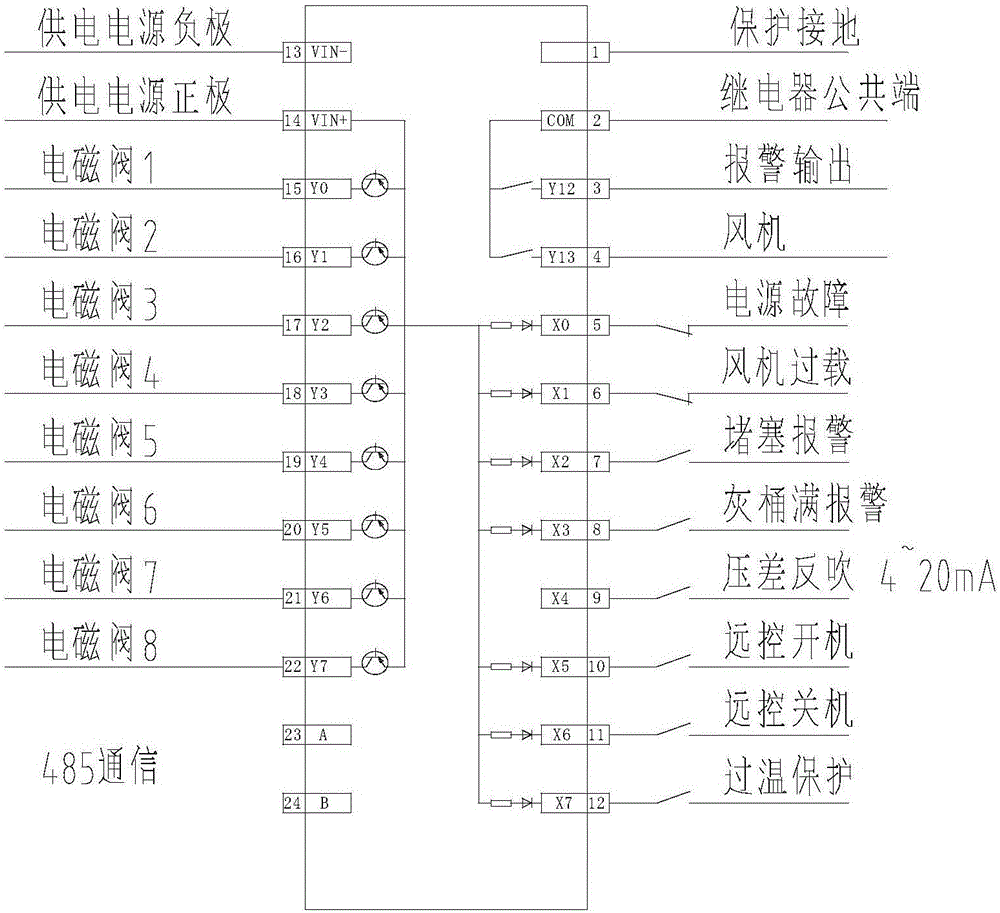

[0033] Such as figure 1 with figure 2 As shown, the present invention discloses a special control system for industrial dust removal equipment, including a controller, a power detection module, a pressure detection module, a temperature detection module, a material level detection module, an alarm output module, and an RS485 communication module;

[0034] The power detection module, pressure detection module, temperature detection module and material level detection module are all connected to the input terminal of the controller, and are respectively used to detect the power failure of the industrial dust removal equipment, the pressure difference value of the inner and outer surfaces of the filter cartridge, and the temperature of the filter cartridge. and talc powder level in the duster;

[0035] The alarm output module is connected with an output termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com