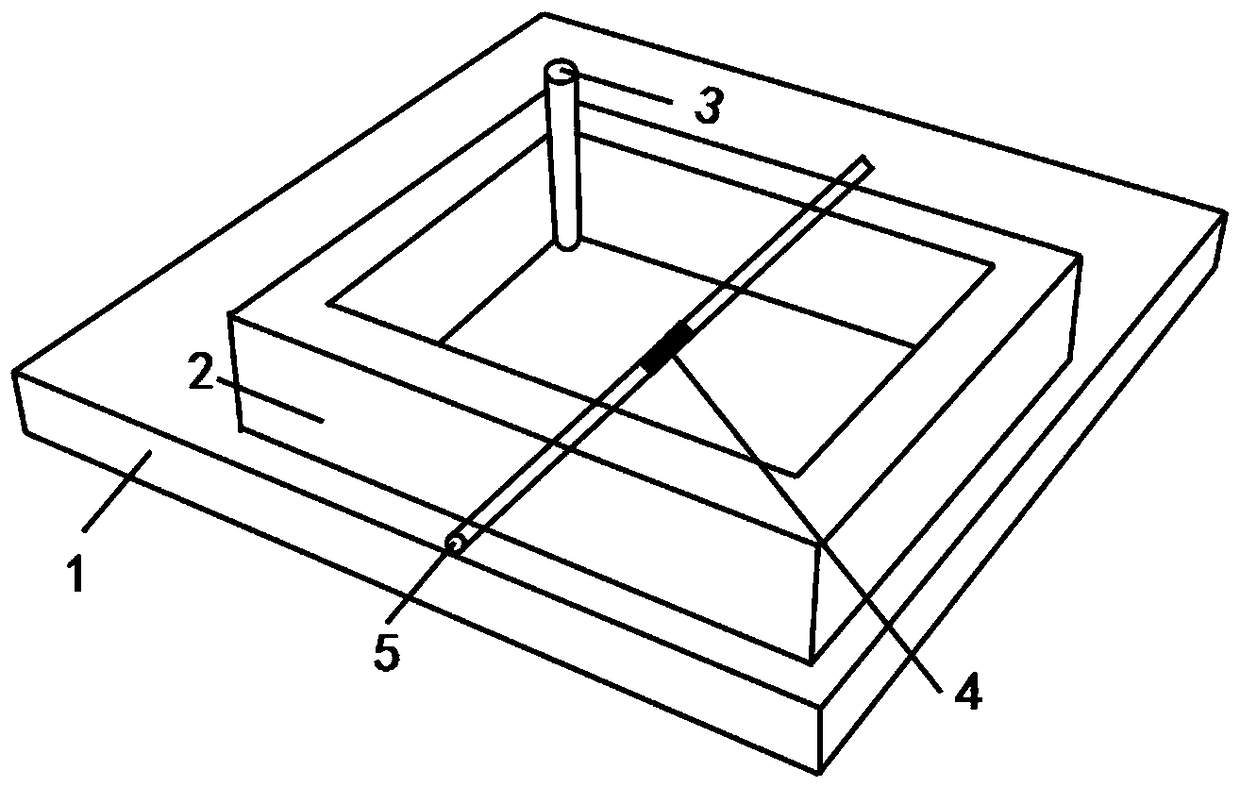

Photothermal waveguide-based microfluidic chip and its microfluidic method

A microfluidic chip and microfluidic technology, applied in the field of optofluidics, can solve problems such as functional limitations of optically controlled microfluidics, single fluid flow form, scattering of optical components, etc., and achieve fast, convenient and low-cost manufacturing methods , Stable effect of stimulating heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

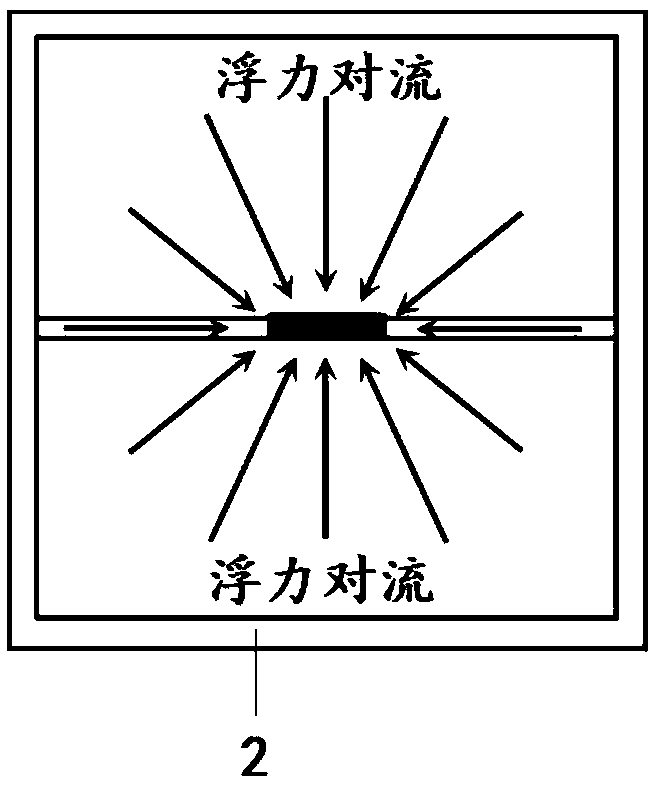

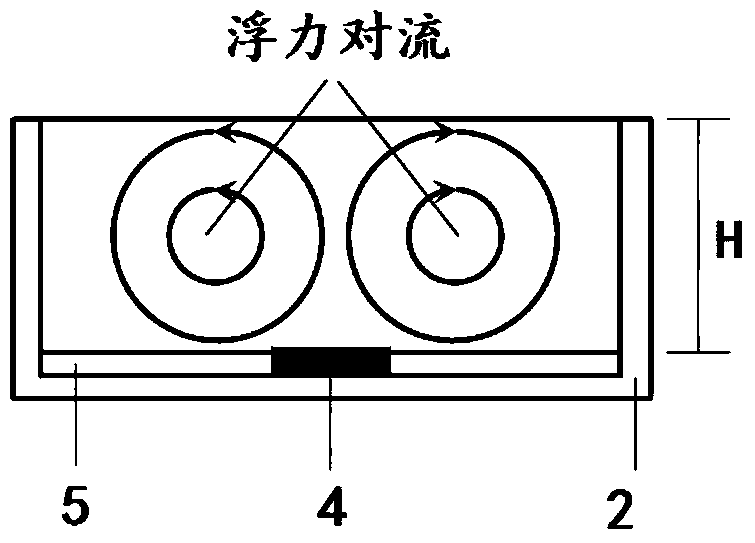

[0044] This embodiment primarily produces a vertical vortex flow dominated by buoyant convection. In this embodiment, the microfluidic pump injects more liquid to form a thicker fluid layer, and the thickness of H is 30-100 μm. At this time, the heat that excites the photothermal waveguide in the microfluid diffuses in the microfluid, and the microfluid close to the heat source Density decreases due to local expansion due to increased temperature. This redistribution of density within the microfluidics creates the buoyancy driving force. The direction of the driving force is vertical, so the driving fluid flows from the low position to the high position, and then from the high position to the low position, so that the vertical vortex is formed in such a cycle. The vertical direction of its convection is as Figure 2b shown. At the same time, since the direction of thermal diffusion is axisymmetric to the photothermal waveguide, the horizontal direction of the generated conv...

Embodiment 2

[0046] This embodiment primarily produces a horizontal vortex flow dominated by thermocapillary convection. In this embodiment, the microfluidic pump injects less liquid to form a thinner fluid layer, the thickness of H is 5-20 μm. At this time, the heat that excites the photothermal waveguide in the microfluid diffuses in the microfluid, and on the surface of the microfluid, The surface tension of the microfluidics near the center becomes smaller as the temperature increases. This redistribution of microfluidic surface tension creates shear stress. Since this phenomenon only occurs on the microfluidic surface, the direction of the driving force is horizontal, so the driving fluid flows from the low surface tension region (high temperature region) to the high surface tension region (low temperature region), and thus forms a horizontal vortex. Its convective direction is as Figure 3a shown. Since the direction of thermal diffusion is axisymmetric to the microfluidic surface...

Embodiment 3

[0048] In this embodiment, horizontal and vertical mixed vortex flows are mainly generated. The micro-flow pump injects an appropriate amount of liquid so that the thickness H of the micro-fluid is 20-30 μm. At this time, the redistribution of the density inside the microfluid and the surface tension on the surface of the microfluid is caused by exciting the photothermal waveguide in the microfluid. The former forms buoyant convection, the latter forms thermocapillary convection, and the two types of convection overlap each other.

[0049] Embodiments of the present invention and experimental operations are described in further detail below in conjunction with examples and drawings, but the embodiments of the present invention are not limited thereto.

[0050] A single-mode silica fiber (SMF-28, Corning Company, USA) was drawn by flame heating stretching method, and a micro-nano waveguide with a diameter of 1.0 μm and a length of 2 mm was drawn. The photothermal waveguide is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com