Rinsing device used for filling beverage bottles

A beverage bottle and mounting frame technology, which is applied to cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of high cleaning cost, easy pollution, waste of resources, etc., to avoid low efficiency, easy to use, The effect of meeting the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

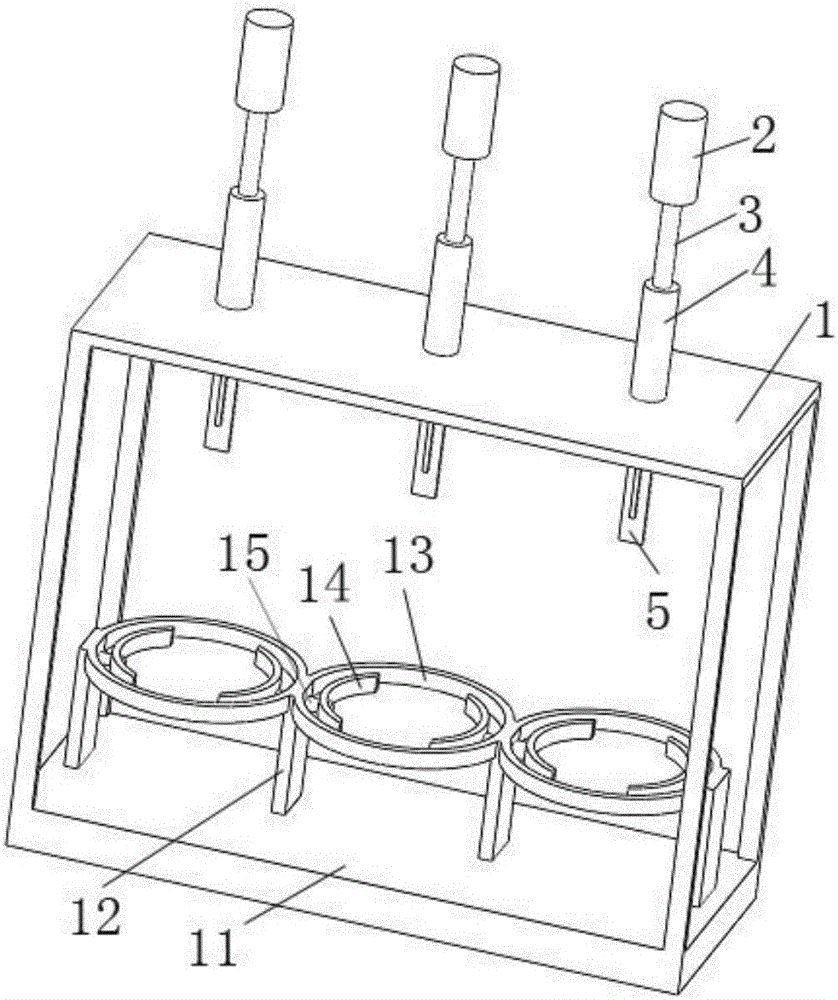

[0016] see figure 1 , a scrubbing device for filling beverage bottles, comprising a mounting frame 1, a clamping assembly and a scrubbing assembly;

[0017] The mounting frame 1 is a rectangular frame, the sides of which are open, and the top surface of the bottom plate 11 of the mounting frame 1 is distributed with four support plates 12, and clamping is provided between two adjacent support plates 12. components;

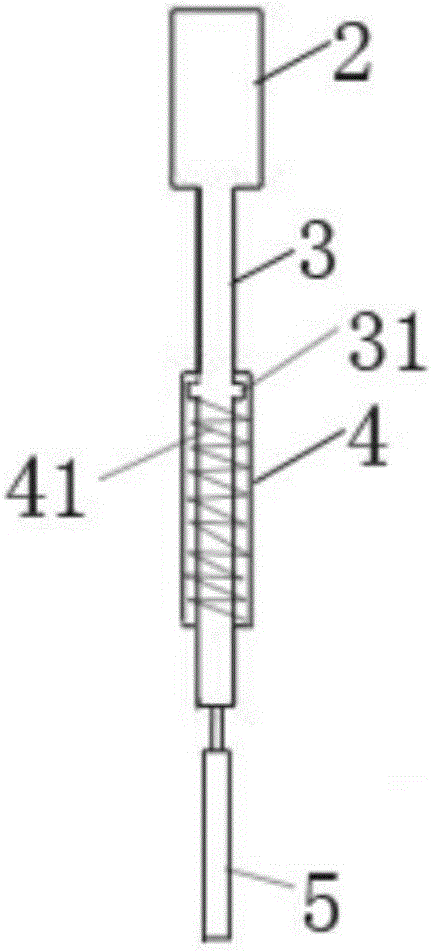

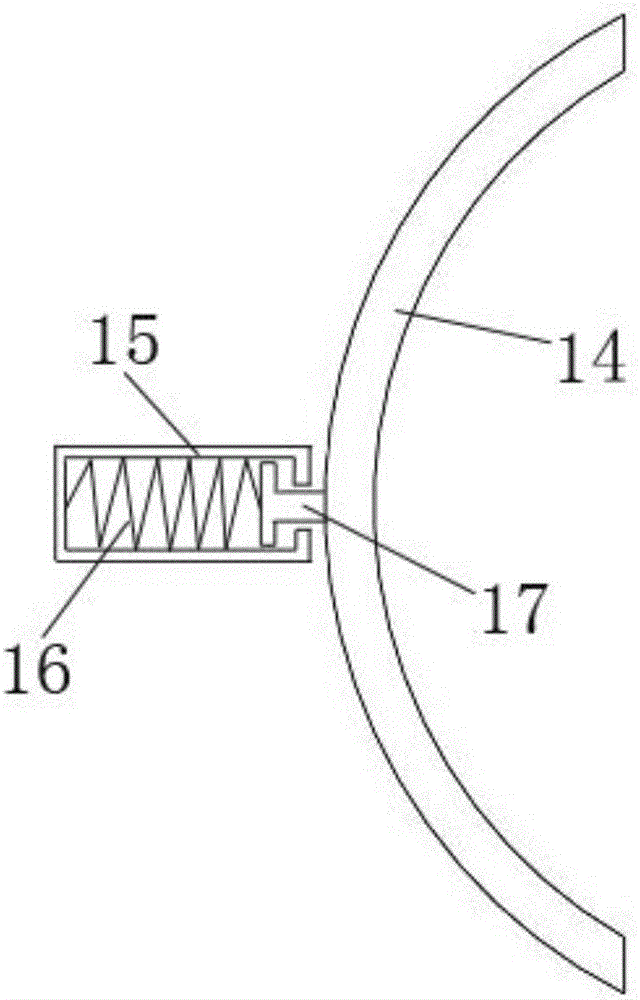

[0018] The clamping assembly includes an outer ring 13 and two arc-shaped plates 14; the outer ring 13 is horizontally arranged on the tops of two adjacent support plates 12, and the opposite sides of the inner wall of the outer ring 13 protrude laterally with limiting tubes 15 , the first spring 16 is horizontally arranged in the limit tube 15; the two arc-shaped plates 14 are respectively arranged at the limit tube 15 places on opposite sides of the outer ring 13, and the outer wall of the arc-shaped plate 14 is arranged radially. Connecting rod 17 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com