Solid waste extraction system and method thereof

A solid waste extraction technology, applied in solid waste removal, chemical instruments and methods, transportation and packaging, etc., can solve the problem of long oscillation reaction time, insufficient extraction reaction, inconvenient storage and measurement of toxic substances, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

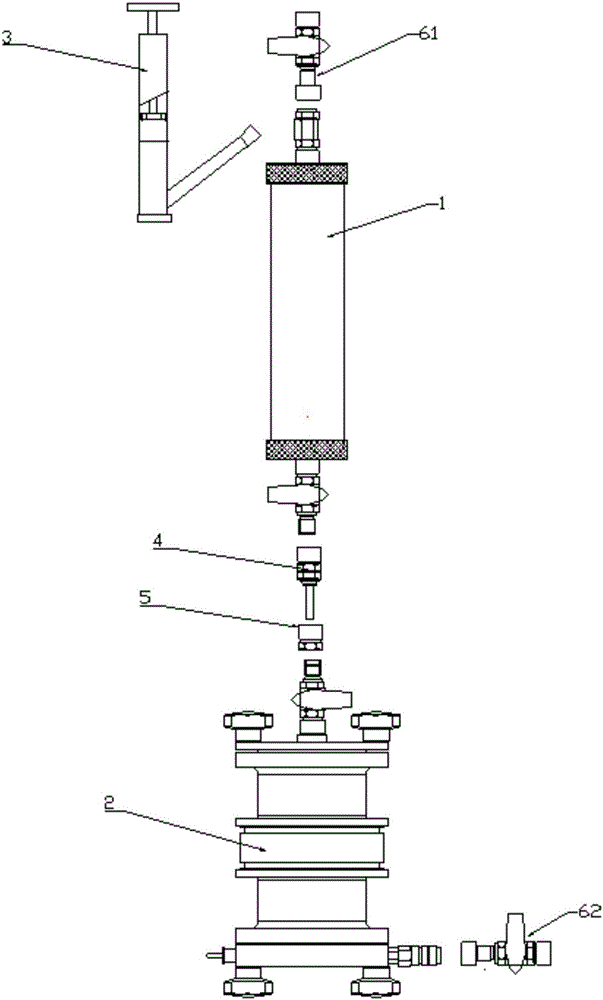

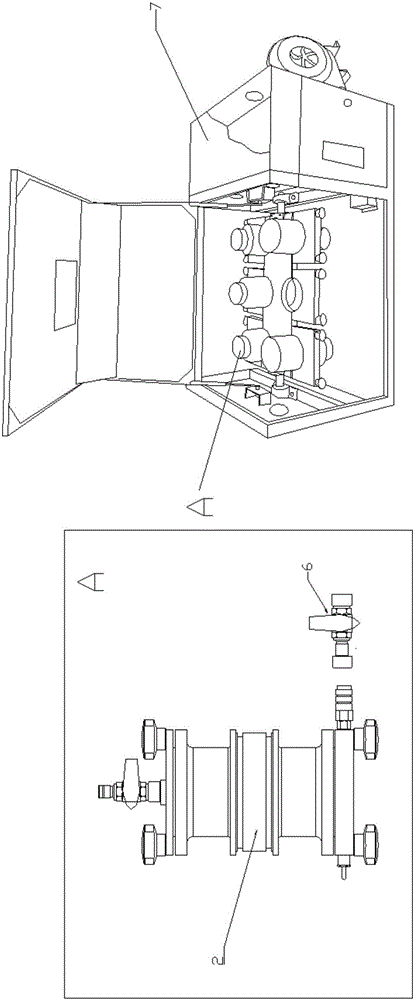

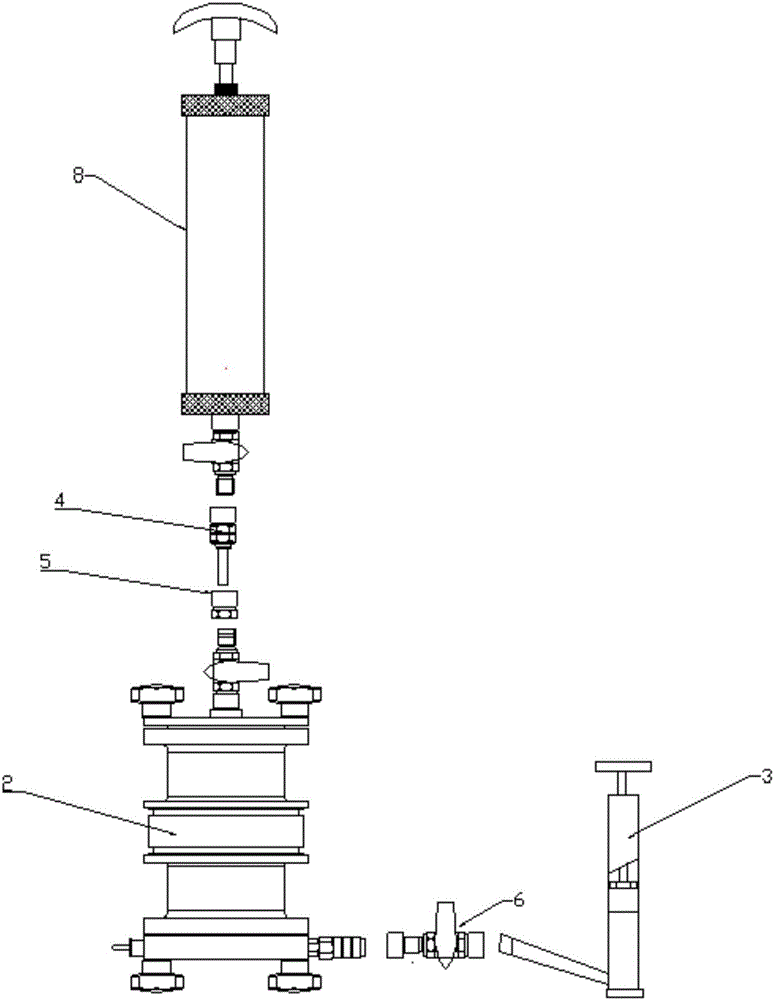

[0074] Such as Figure 1~3 As shown, the present invention provides a solid waste leaching system, including a leaching liquid addition part, a vibrating leaching part and an extract collection part, such as figure 1 As shown, the leaching and liquid addition part includes a liquid addition device 1, an extraction device 2 and a pressurization device 3, and the liquid addition device 1 and the extraction device 2 are connected through a connecting piece 4 and a connecting piece 2 5, so The air inlet 212 of the leaching device 2 is connected to a connector three 62, and the pressurizing device 3 is connected to the liquid adding device 1 through a connector four 61; as figure 2 As shown, the oscillating extraction part includes an extraction device 2 and an overturning oscillator 7, and the extraction device 2 is fixed in the overturning oscillator 7; as image 3 As shown, the extract collecting part includes a pressurizing device 3, an extracting device 2 and a collecting de...

Embodiment 2

[0127] On the basis of Example 1, a three-way joint is provided between the valve 213 and the second connector 5 during the extract collection process. Connect the collection device 1 and the collection device 2 through a three-way joint, connect the collection device 1 to the port 1 of the tee joint through the first connecting piece 1 and the first connecting piece 2, and connect the port 2 of the tee joint to the valve of the leaching device connection, the port three of the three-way joint is connected to the collection device two through the second connection part one and the second connection part two, and the pressurizing device is connected to the air inlet of the extraction device through the connection part five;

[0128] Open the collection safety valve of collection device 1, the valve of the leaching device and the safety valve of connector 5, close the collection safety valve of collection device 2, and pressurize the leaching device through a pressurizing device ...

Embodiment 3

[0132] On the basis of Embodiment 1, a three-way joint may be provided between the valve 213 and the second connector 5 during the liquid addition process. Connect liquid adding device 1 and liquid adding device 2 through a three-way joint, connect liquid adding device 1 to port 1 of the three-way joint through the first connecting piece 1 and first connecting piece 2, and connect port 2 of the three-way joint to the liquid adding Device 1 is connected, and port 3 of the tee joint is connected to liquid-filling device 2 through the second connecting piece 1 and second connecting piece 2, and the pressurizing device is connected to liquid-filling device 1 and liquid-filling device 2 through connecting piece 4 respectively. ; It can realize the requirement of adding different leaching reactants during the liquid addition process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com