Side body forming mould for automobile

A technology for forming molds and automobiles, which is applied in the direction of forming tools, manufacturing tools, vehicle parts, etc., can solve the problems of affecting product quality image, high scrap rate, and scrapping the whole body, so as to improve drawing stability and drawing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

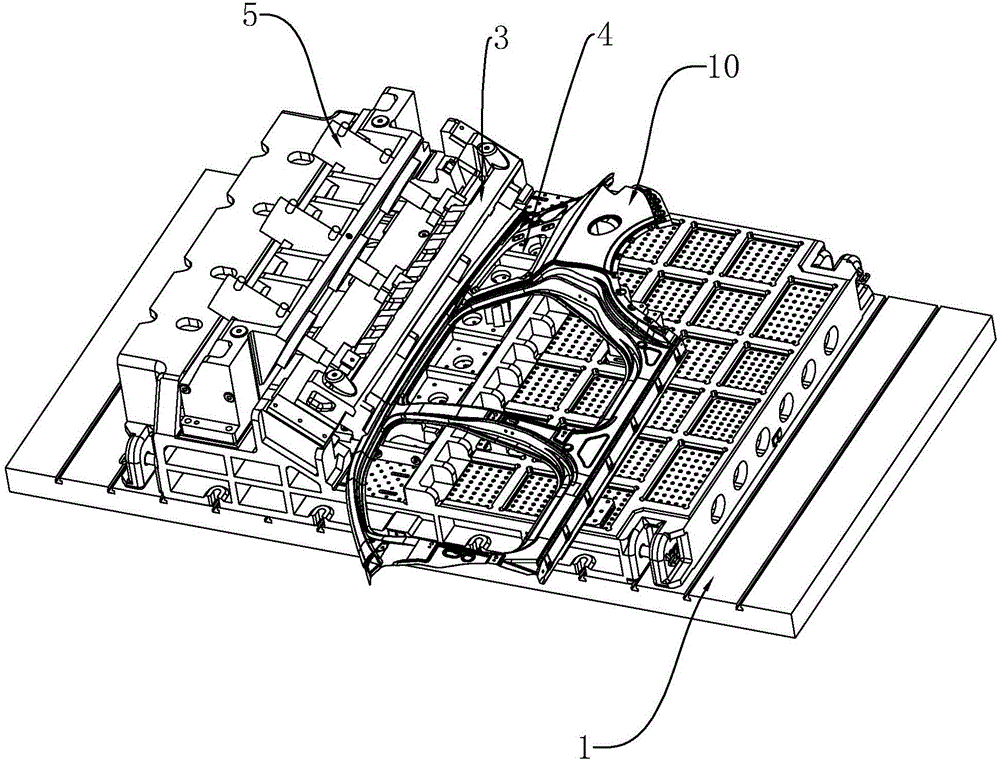

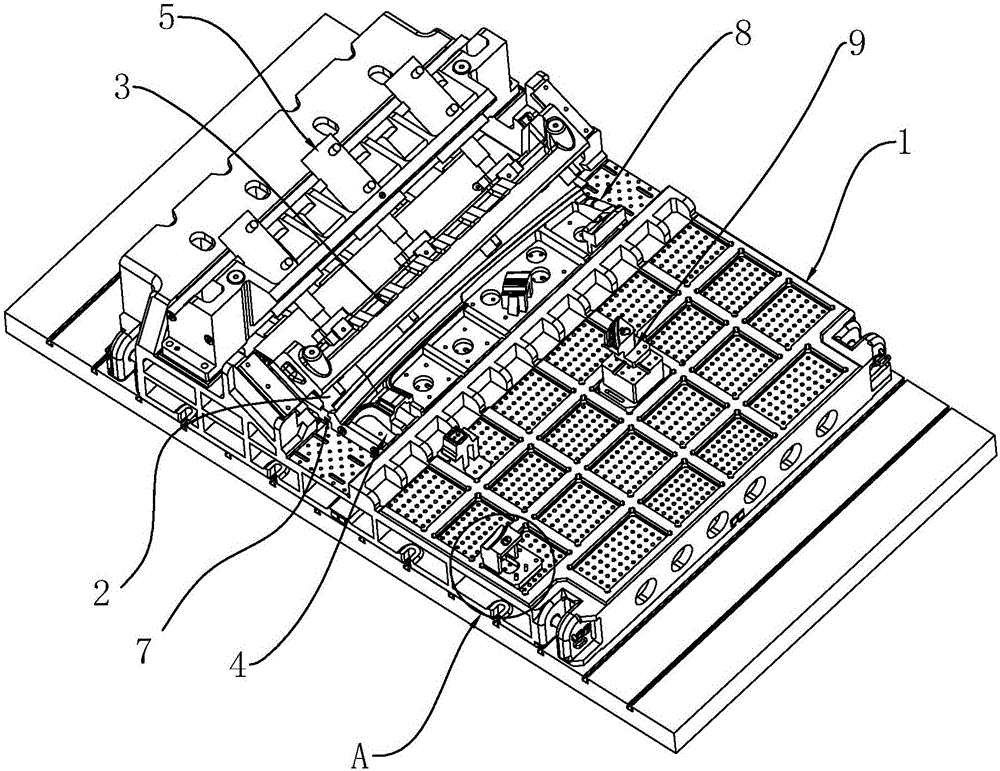

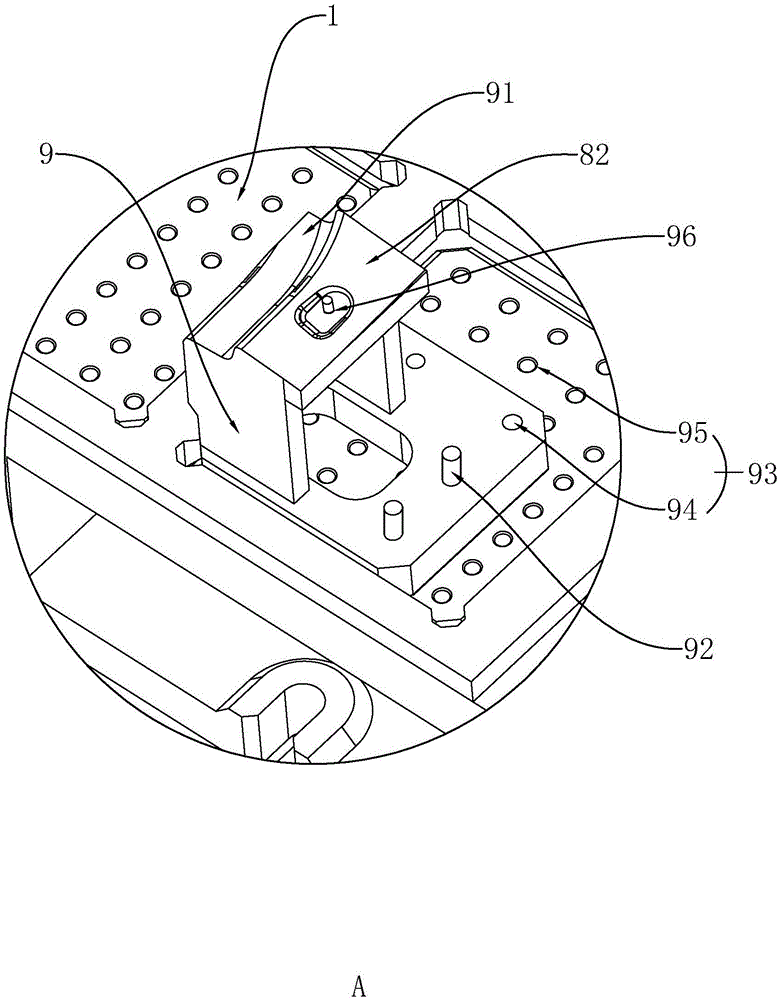

[0039] refer to Figure 1 to Figure 10 Further explanation of the automotive side wall forming mold.

[0040] A car side wall forming mold, such as figure 1 , figure 2 with Figure 10 As shown, it includes base 1, front pressing core 2, side pressing core 3, fixed mold pressing core 4 fixedly arranged on base 1, fixedly arranged on base 1 and used to drive side pressing core 3 to tilt downward The first drive assembly 5 moving towards the direction of the fixed die pressing core 4 and the second drive assembly 6 arranged on the base 1 for driving the front pressing core 2 to slide in the direction of the front pressing core 2 on the base 1; When the core 4, the side binder core 3 and the front binder core 2 are closed, a shaping cavity 7 for drawing and forming the side wall is formed, and the side binder core 3 and the front binder core 2 are set to be equal in length, and the fixed mold is pressed. The length of the material core 4 is longer than that of the side pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com