Serial-parallel elastically driven linear movement unit

An elastic drive, linear motion technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of slow movement, poor impact resistance, unstable output, etc., to achieve stable output, increase support capacity, and increase load capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

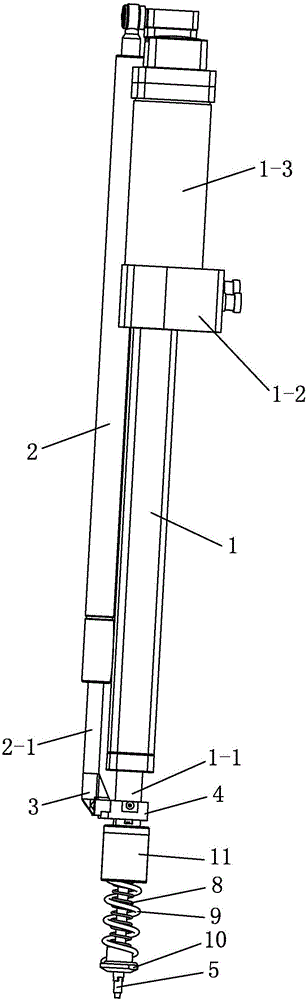

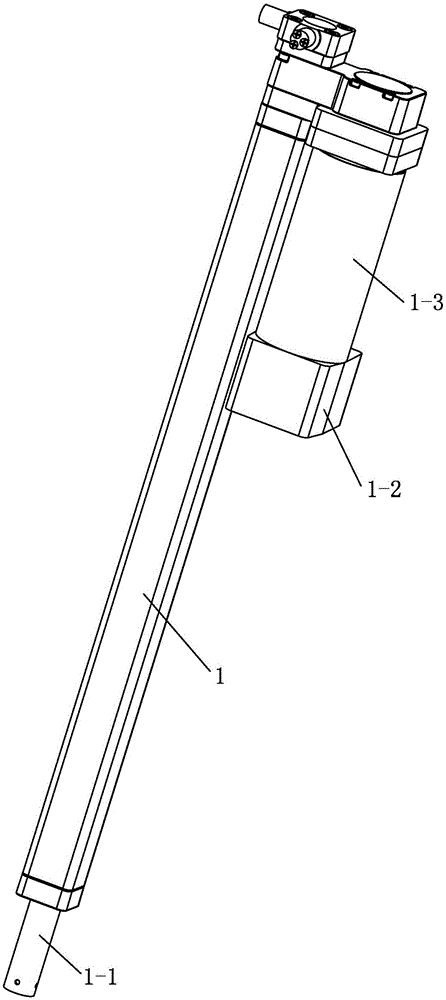

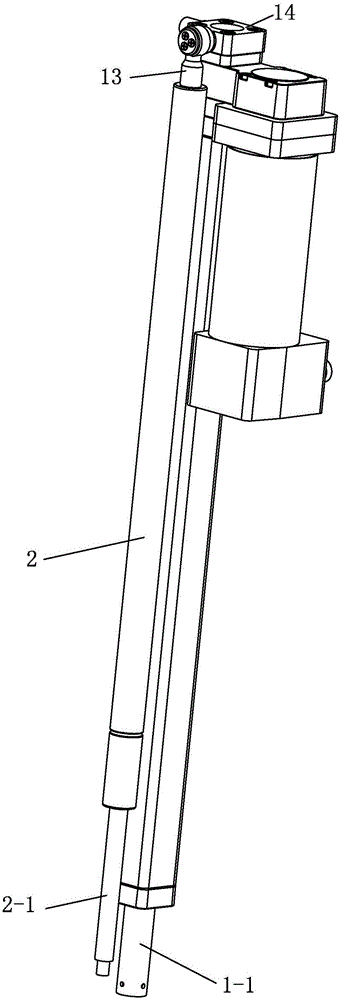

[0015] combine Figure 1-Figure 5 Explain that a series-parallel elastically driven linear motion unit of this embodiment includes an electric linear actuator 1, and it also includes a gas spring 2, a gas spring extension shaft connector 3, an actuator extension shaft connector 4, Shaft 5, sliding sleeve 6, upper thin spring 7, lower thin spring 8, lower thick spring 9 and lower spring fixing part 10;

[0016] The top of the cylinder body of the electric linear actuator 1 is rotatably installed with the gas spring 2, and the gas spring extension shaft 2-1 of the gas spring 2 is connected with the actuator extension shaft 1-1 of the electric linear actuator 1. 1 are arranged in parallel, the actuator extension shaft 1-1 of the electric linear actuator 1 is a hollow cavity, the upper section of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com