A centralized monitoring system and method for a substation inspection robot

A technology of inspection robot and centralized control system, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as difficulty in operation, difficulty in ensuring accuracy, waste of manpower and material resources, and achieve the effect of efficient use of big data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

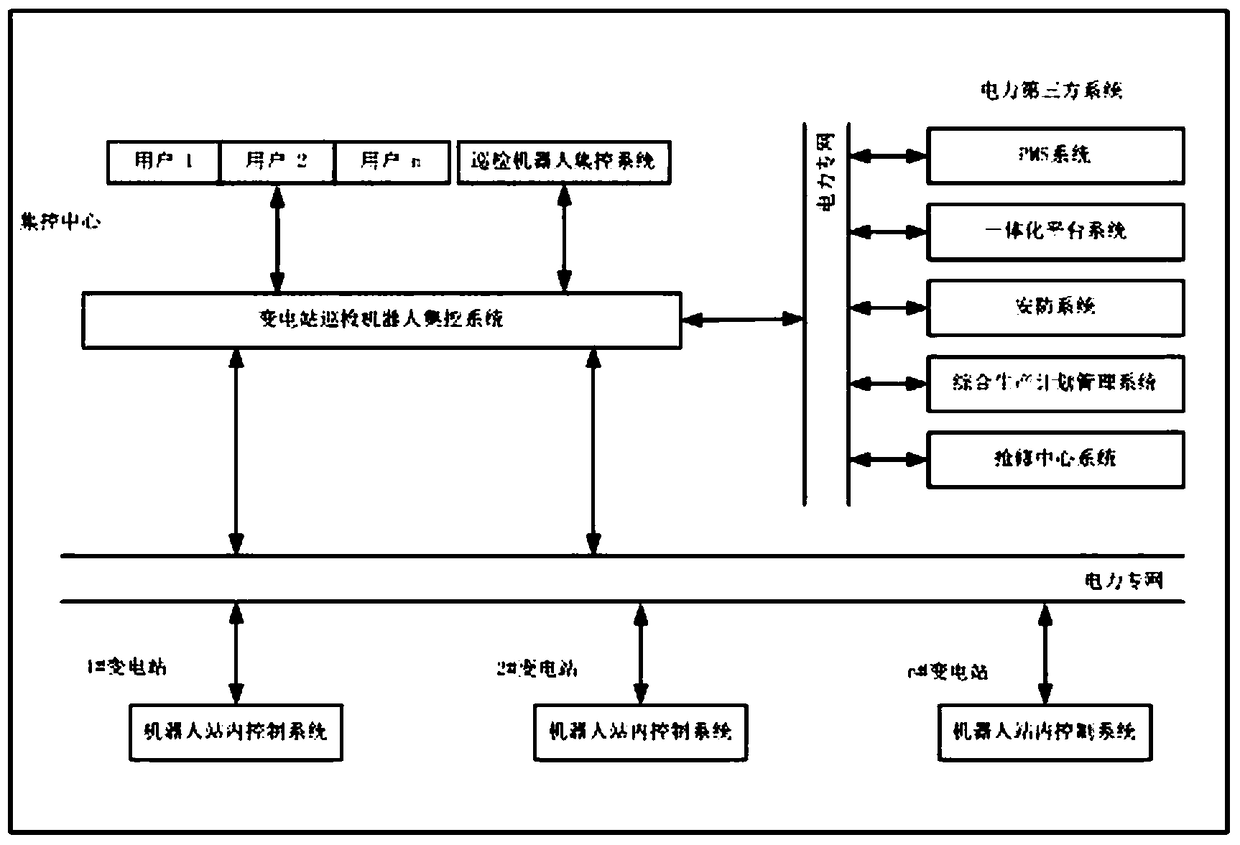

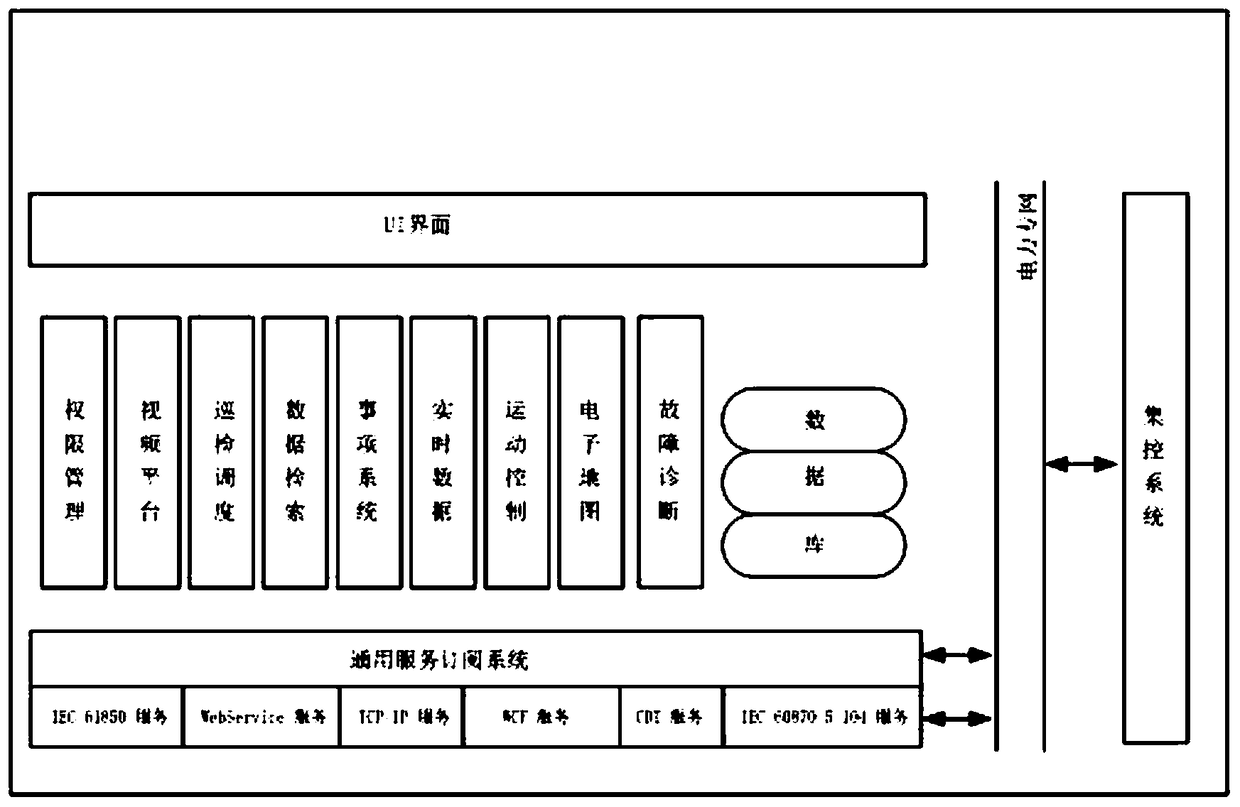

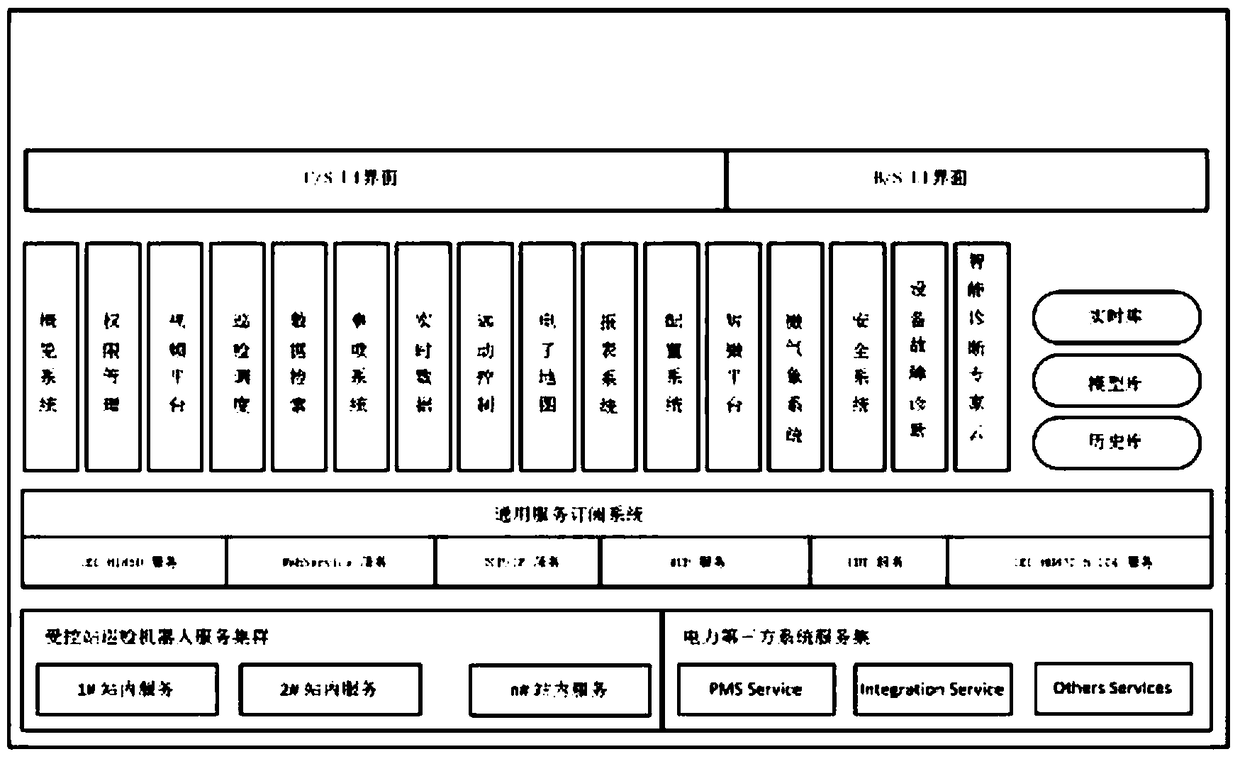

[0064] A centralized monitoring system for substation inspection robot cluster inspection, including the substation inspection robot centralized control system deployed in the centralized control center, multi-user client, third-party power system (accessible to PMS system, integrated platform system, security system, integrated production plan management system, emergency repair center system), the inspection robot station control system deployed in remote substations, and the substation inspection robot body. The centralized control system and the multi-user client are connected in a one-to-many manner, allowing local or remote client access based on the electric power private network; the centralized control system and the substation inspection robot station control system are connected in a one-to-many manner access. The centralized control system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com