A nano-filter film transfer cutting tool

A filter film and nanotechnology, applied in workpiece clamping devices, metal processing, manufacturing tools, etc., can solve the problems of high price of filter film, scrapped filter film, etc., to eliminate unsafe factors, protect safety, The effect of safe and reliable preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

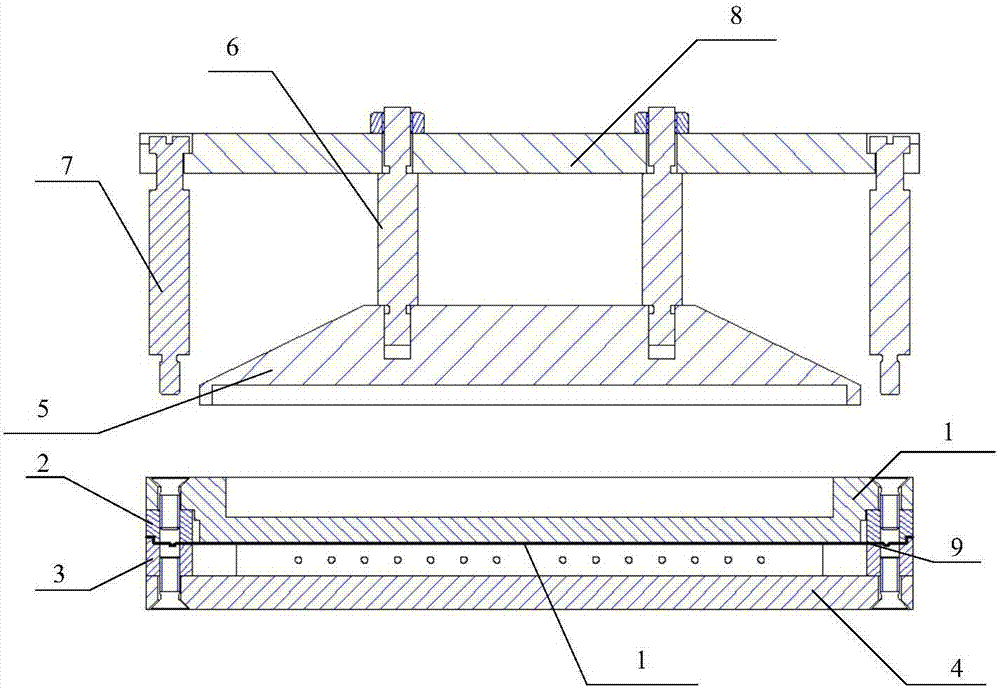

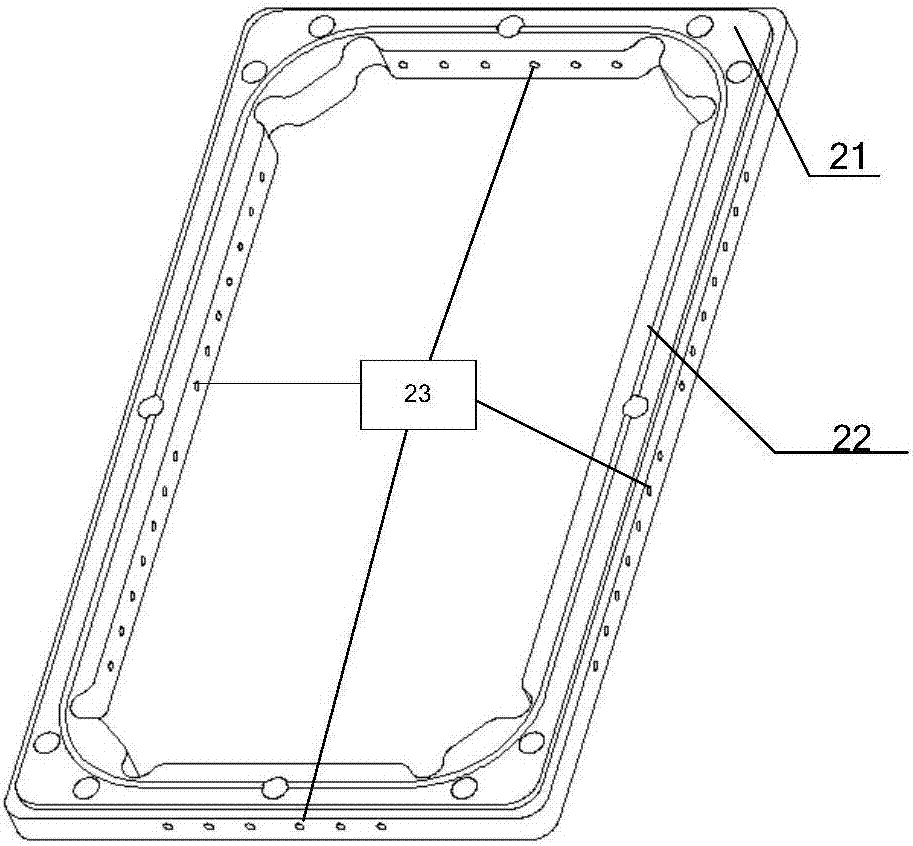

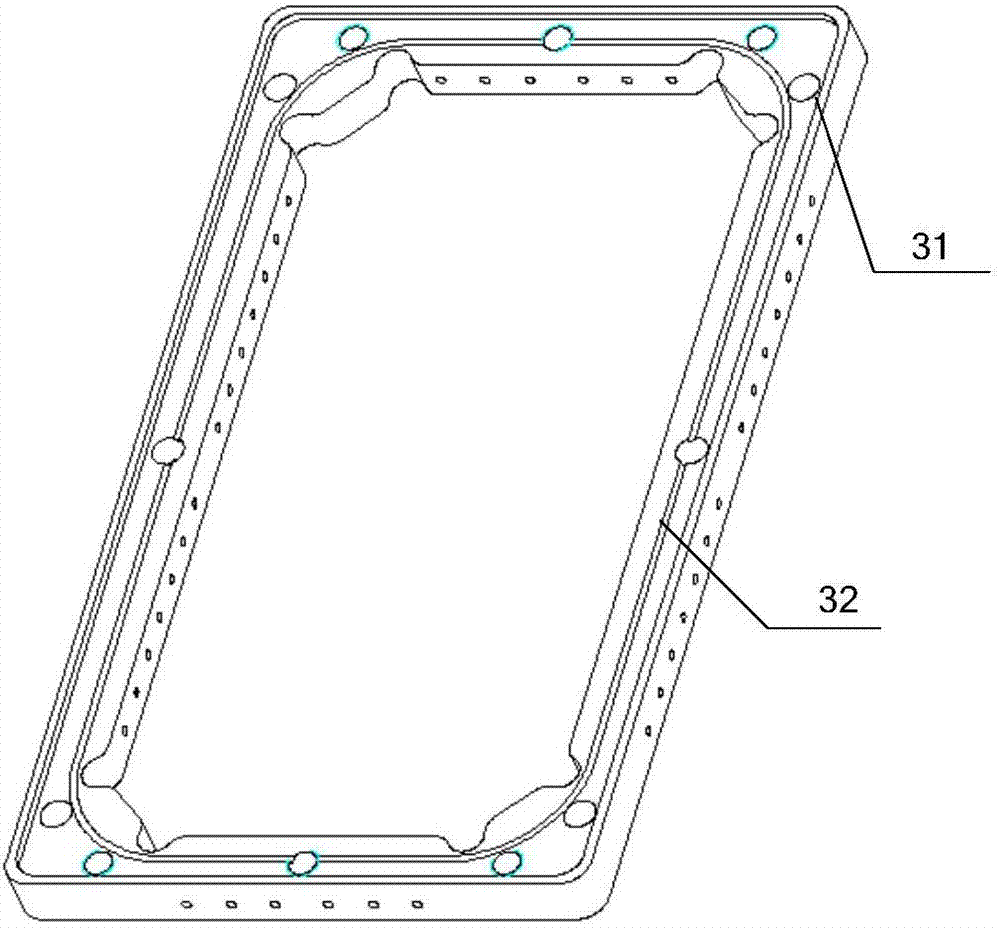

[0021] A kind of nano filter film transfer cutting tool of the present invention, such as figure 1 As shown, the tooling includes the following parts: an upper protective cover 1, an upper compression frame 2, a lower compression frame 3, a lower protective cover 4, a shape cover 5, a support column 6, an adjustment guide column 7, and a beam 8. Such as figure 2 and 3 As shown, the upper compression frame 2 and the lower compression frame 3 are both hollow square frame structures, and the size and shape of the two are consistent; the edge of the upper compression frame 2 is processed with a circle of protrusions, forming a first step 21 , the first step 21 is processed with a circle of arc grooves 22; the lower compression frame 3 is processed with a circle of grooves at the position corresponding to the first step 21 of the upper compression frame 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com