Running method of bamboo chip cutting machine based on construction field usage

An operation method and cutting machine technology, applied in mechanical equipment, sugarcane machining, wood splitting device, etc., can solve the problems of inability to realize coherent reciprocating action, complicated control mode, and easy damage of equipment, and achieve fast and stable contact, Easy to operate, not easy to damage the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

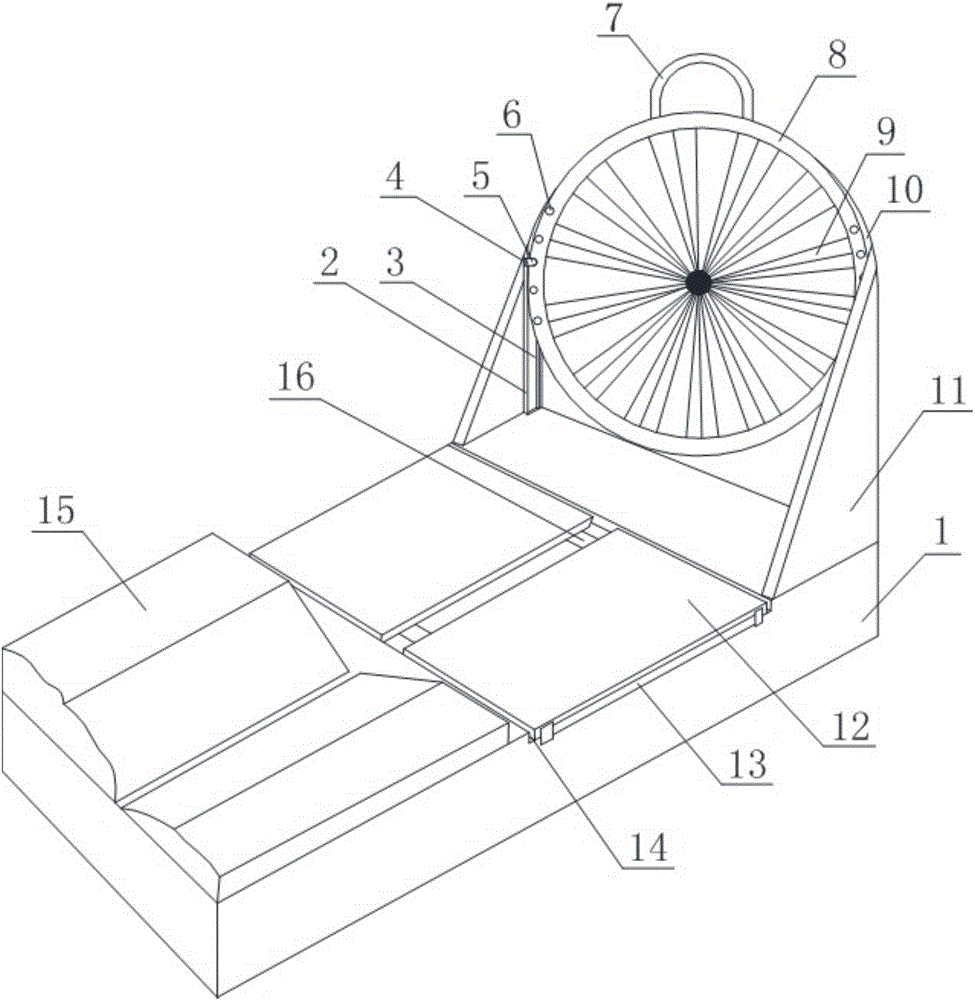

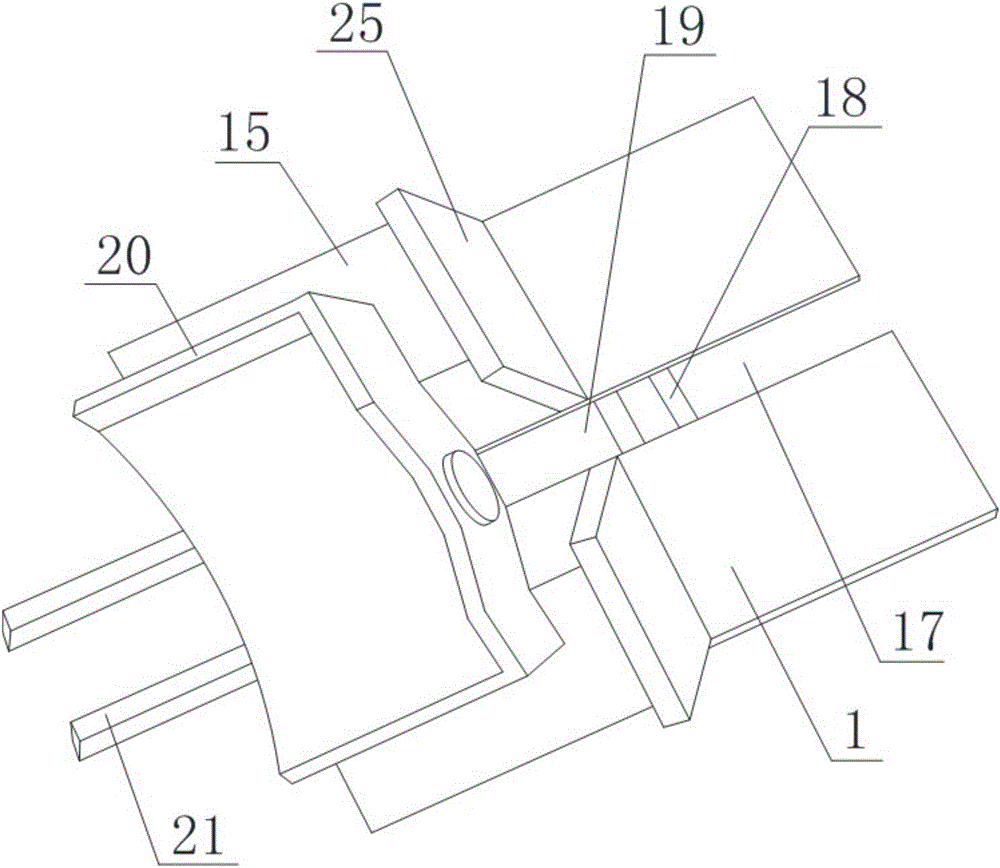

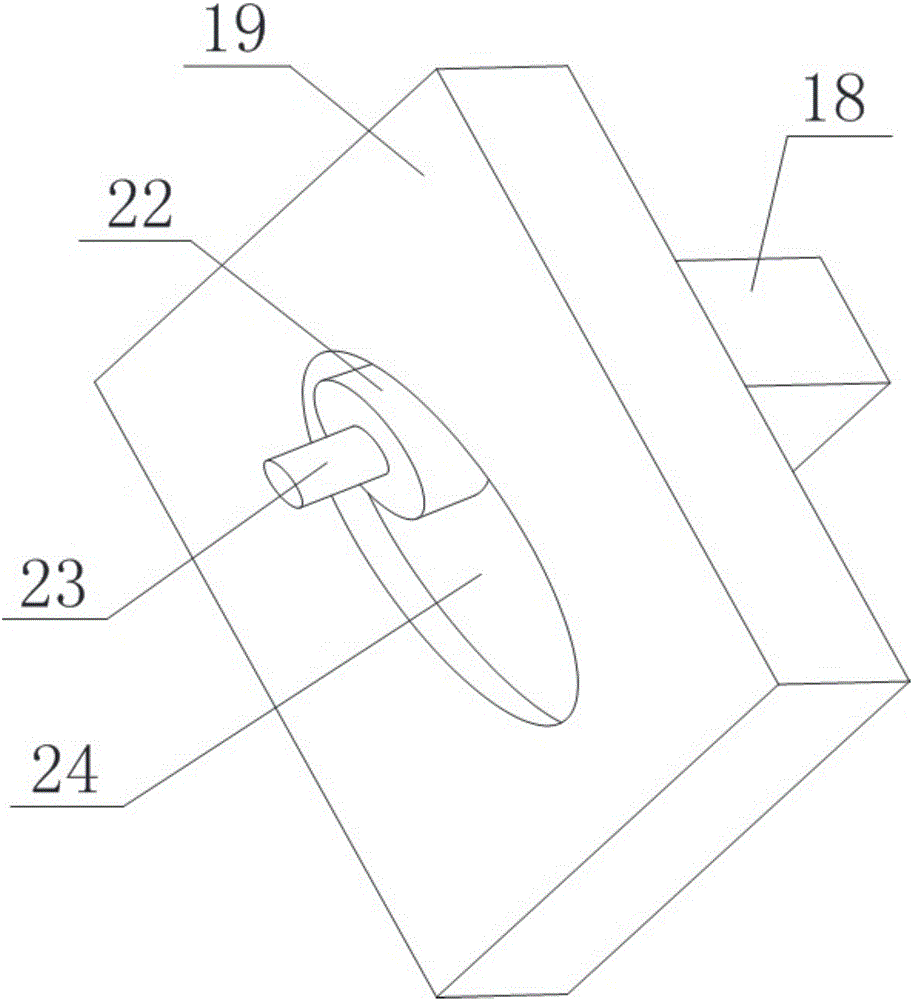

[0030] Such as figure 1 , figure 2 , image 3 Shown, a kind of operation method based on the bamboo cutting machine used at the construction site, its hardware equipment includes support frame and cutting platform 1, and cutting platform is arranged on support frame top and is fixed with support frame top, and cutting platform 1 is provided with Through the guide groove 17 of the cutting platform 1, two groups of cutting knives are arranged on the top surface of the cutting platform 1, and a motor is arranged below the cutting platform 1 as a power mechanism. The mechanism is arranged below the cutting platform 1, and the transmission mechanism is provided with a connecting column. A reversing plate 19 is arranged between the connecting column and the cutting platform 1. The bottom of the reversing plate 19 is concaved to form a reversing groove 24. The top of the connecting column is arranged on the In the reversing groove 24, the bottom end is fixed with the transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com