Method and apparatus for preparing mixture and removing sticky material on scale

A technology for mixing materials and weighing hoppers, which is applied in the field of preparing mixed materials and removing sticky materials in the weighing bucket, can solve the problems of difficulty in removing the sticking materials in the weighing bucket, the cleaning method that cannot be washed with water, and the cleaning method cannot be used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

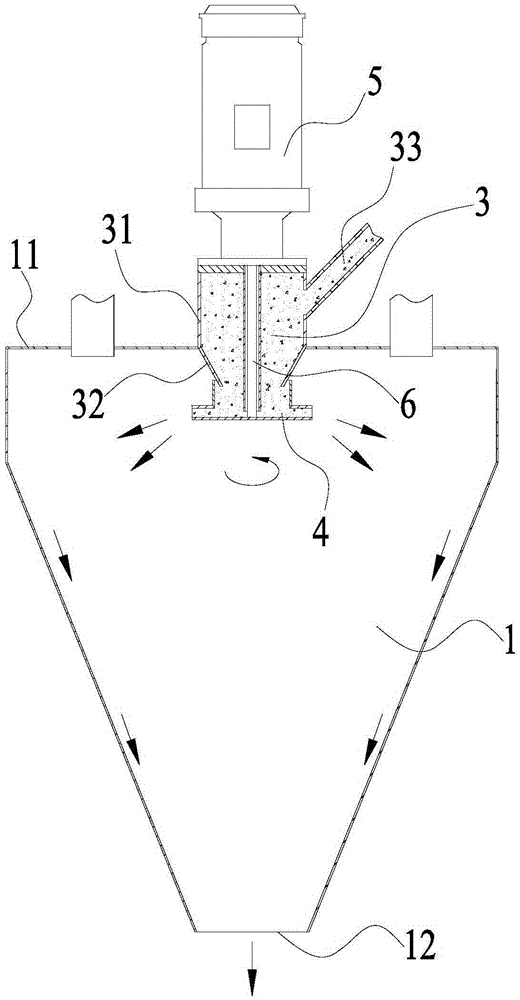

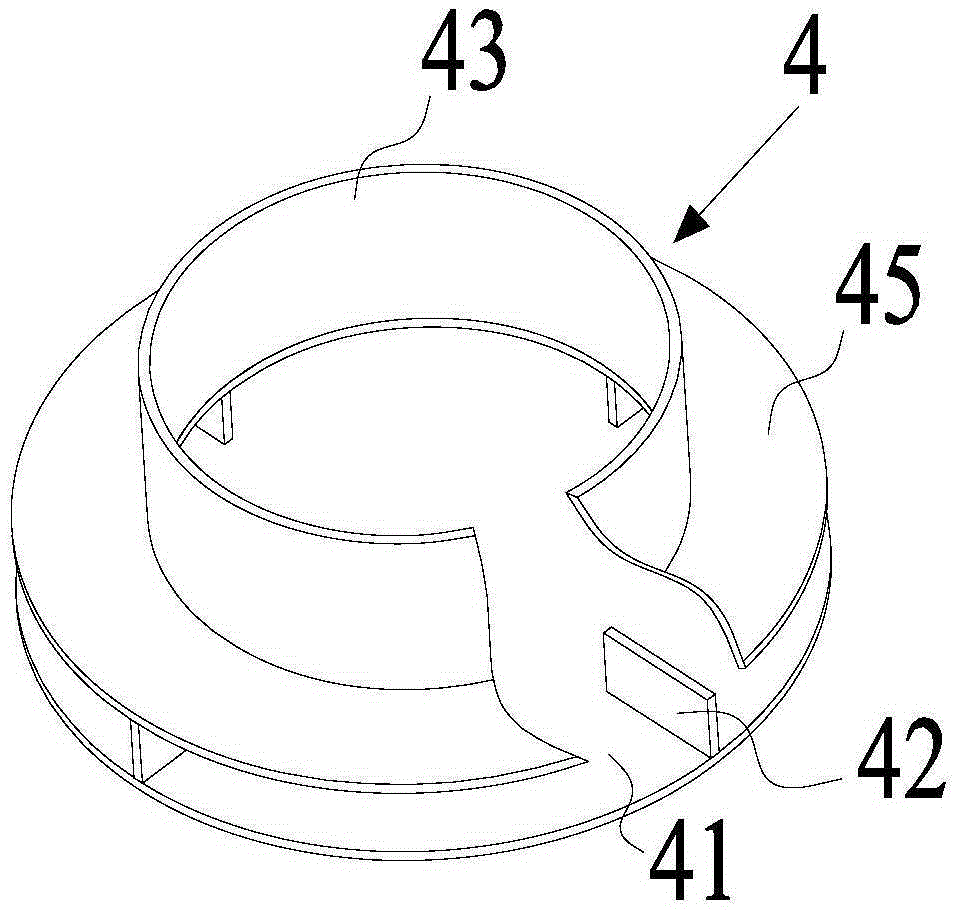

[0045]The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

[0046] In the present invention, unless otherwise stated, the directional words used such as "up, down, left and right" generally refer to up, down, left and right as shown with reference to the accompanying drawings; "inside, outside" Refers to the inside and outside of the contour of each component itself.

[0047] According to one aspect of the present invention, there is provided a method for removing sticky material from a scale hopper, the method comprising: causing a first solid material to flush the sticky material in the scale hopper at a predetermined speed, wherein the sticky material in the scale hopper is made of a second solid state material. The material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com