Anti-broken core mechanical pencil

A propelling pencil, anti-breaking technology, applied in mechanical pencils, printing, writing utensils, etc., can solve the problems of broken core, lead lead broken into many knots in the tip sleeve, lead core broken in the tip sleeve, etc., to achieve convenient use, Reduce the movable distance and reduce the effect of core breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

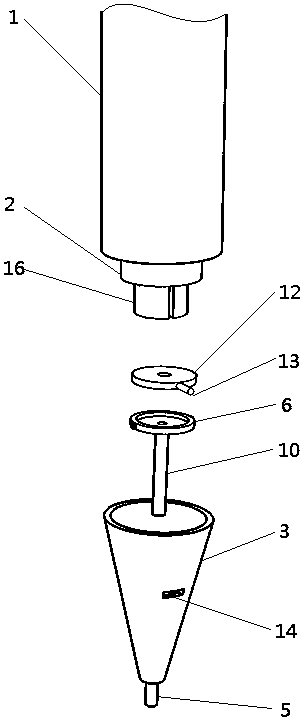

Embodiment 1

[0023] Embodiment one, such as image 3 , Figure 5 As shown, when selecting the manually controlled point cover 3 to cooperate with the pen barrel, when installing the lead core, first move the lever 13 to move the A pressing plate 12 upwards, the pressure on the pressing plate 6 decreases, and the pressure plate 6 below The powder filler 11 is in a loose state, and then the lead core installation process is carried out in the same way as in the traditional way. The lead core passes through the protective core tube 5, the sealing hose 10, and the chuck 16 successively, and enters the core tube 2.

[0024] After the lead core is installed, turn the lever 13 in the opposite direction, the pressing plate A 12 moves downward, and drives the pressing plate 6 to move downward together, and the pressing plate 6 exerts pressure on the powdery filler 11, and the powdery filler 11 is in a tight state At the same time, the sealing hose 10 is pressed to wrap the lead core, so as to comp...

Embodiment 2

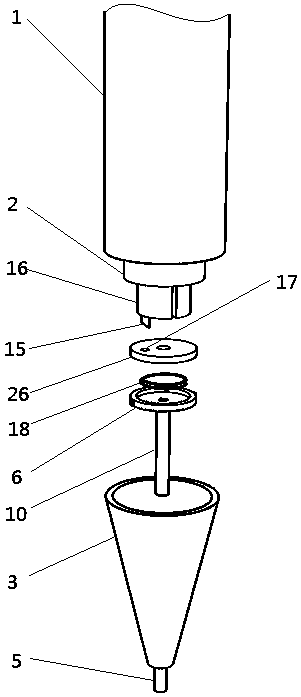

[0025] Embodiment two, such as figure 2 , Figure 4 As shown, when the automatic control point sleeve 3 is selected to cooperate with the pen tube, when the lead core is installed, the core tube 2 needs to be pressed downward, the chuck 16 moves downward and opens, and the wedge-shaped latch 15 at the bottom of the chuck 16 moves together Move down and insert into the cylindrical socket 17, because the bottom of the wedge-shaped bolt 15 is an inclined slope, so it can drive the B pressing plate 26 to rotate, cooperate with the thread to make the pressing plate 12 move upward, the pressure on the pressing plate 6 decreases, and the pressing plate 6 The powder filler 11 below is in a loose state, and then the lead core is installed.

[0026] After the lead core is installed, loosen your finger, the core tube 2 moves upward, the chuck 16 and the wedge-shaped pin 15 move upward together, the wedge-shaped pin 15 is pulled out from the cylindrical socket 17, and under the action o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com