Z-shaped descending conveying device for sliding by dint of self gravity and provided with anti-falling seesaw

A technology of conveying device and seesaw, which is applied in the direction of transportation and packaging, slideway, etc., which can solve the problems of difficult production, accelerated decline of workpieces, easy jamming of workpieces or falling impact, etc., to achieve effective control of the sliding speed and smooth sliding process , the effect of controllable sliding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

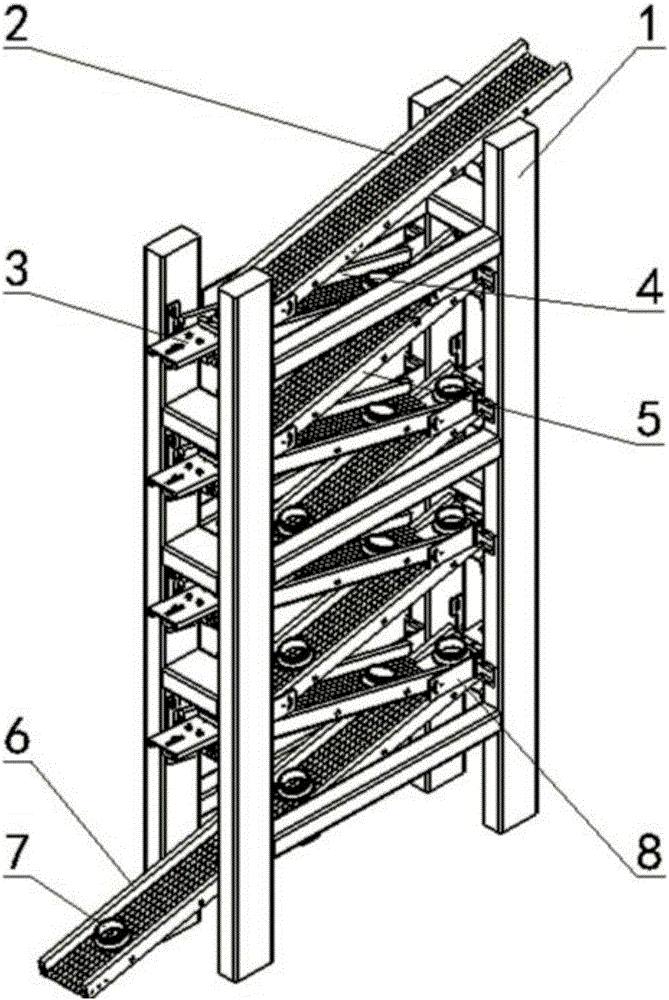

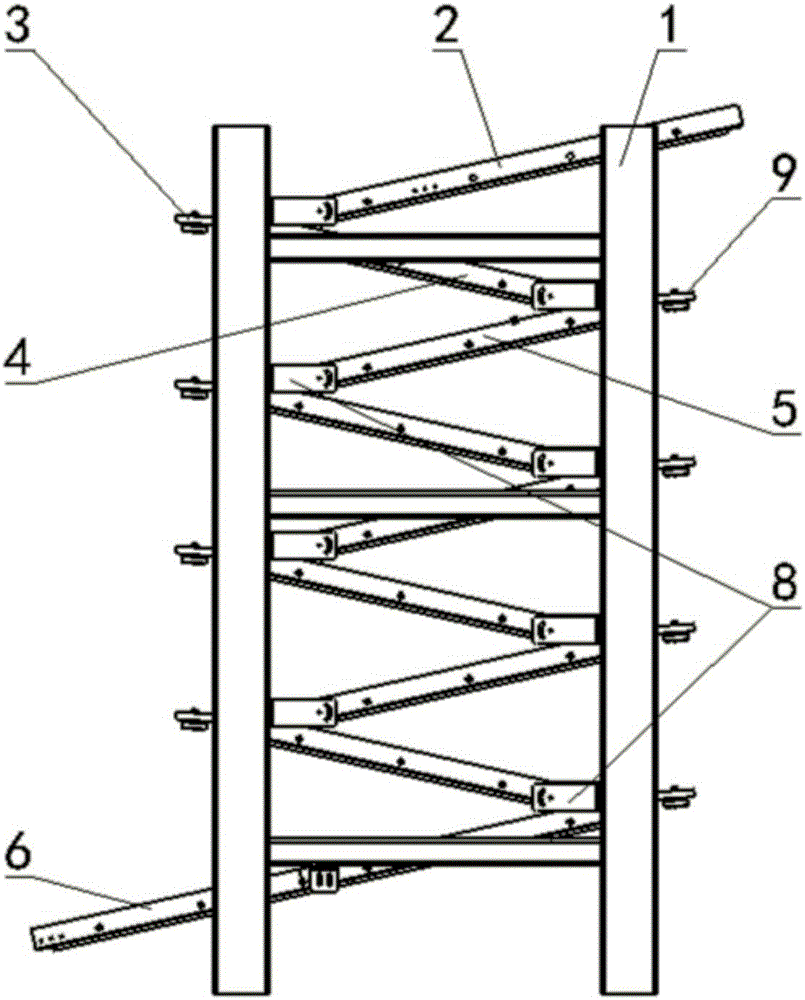

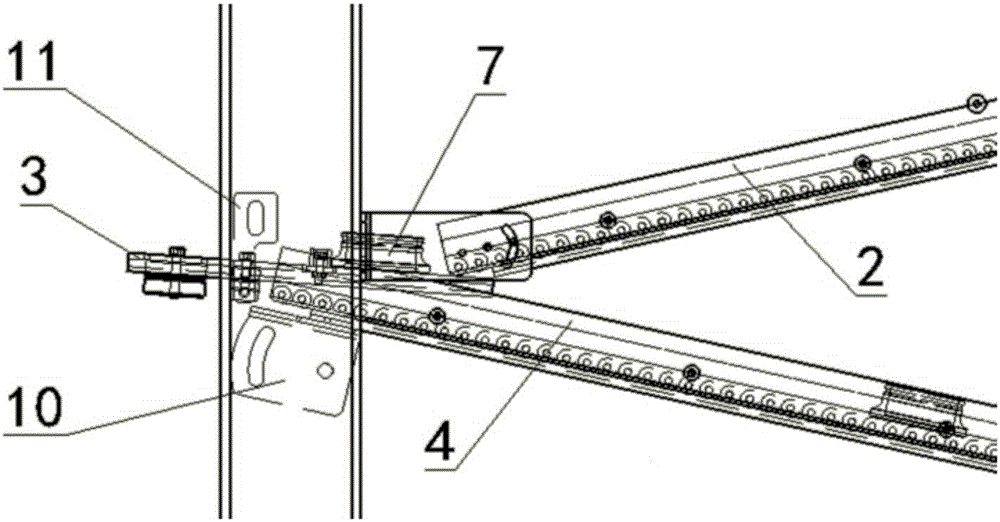

[0022] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as Figure 1 to Figure 4 As shown, the anti-planting seesaw of the present invention relies on the self-gravity sliding Z-shaped descending conveying device to include a mounting frame 1, a feeding slideway 2, an anti-planting seesaw 3, a Z-shaped slideway 4 to the right, and a Z-shaped direction to the right. Left slideway 5, discharge slideway 6, adjustable angle connecting plate 8, reverse anti-planting seesaw 9, adjustable angle mounting plate 10, seesaw connecting plate 11, slide plate 12, counterweight 13, rotating shaft mounting seat 14, Rotating shaft 15, blocking block 16. The workpiece 7 in the figure does not belong to the components included in the device.

[0024] Such as Figure 1 to Figure 3 As shown, the feeding slideway 2 is arranged above the installation frame 1 of the present invention, and the anti-planting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com