Transportation device for water conservancy culvert pipe

A transportation device and water conservancy technology, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve problems such as hidden safety hazards, poor shock absorption performance, slipping down, etc., and achieve the effect of effective fixing and good shock absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

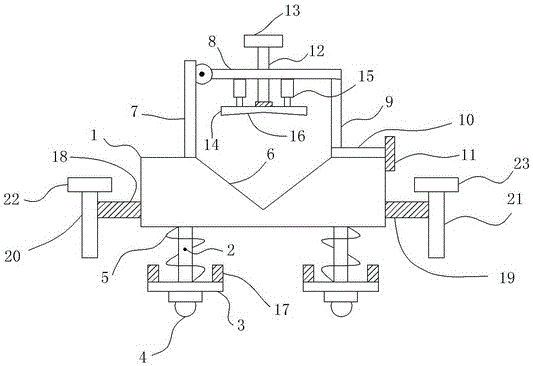

[0013] like figure 1 Shown, a kind of water conservancy culvert transportation device, comprises base 1, is respectively provided with the bottom telescoping rod 2 that extends vertically downwards at the four corners of the bottom of base 1, is provided with mounting seat 3 at the bottom end of bottom telescoping rod 2, when installing The bottom end of the seat 3 is equipped with a traveling wheel 4, and a coil spring 5 is sleeved outside the bottom telescopic rod 2, so as to play a good shock-absorbing and buffering effect in the process of transporting the culvert; There is a bottom V-shaped groove 6, a left vertical bar 7 extending vertically upwards is fixedly connected to the top left end of the base 1, an upper cross bar 8 is hinged at the top of the left vertical bar 7, and the right end of the upper cross bar 8 is also fixedly connected There is a right vertical bar 9, and a right cross bar 10 is fixedly connected to the bottom end of the right vertical bar 9 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com