Hoisting overturning device for concrete tower drum and hoisting overturning method

A concrete and tower technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of complexity, difficulty in hoisting and turning over, etc., and achieve the effect of convenient manufacturing, realization of repeated use, and simple hoisting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

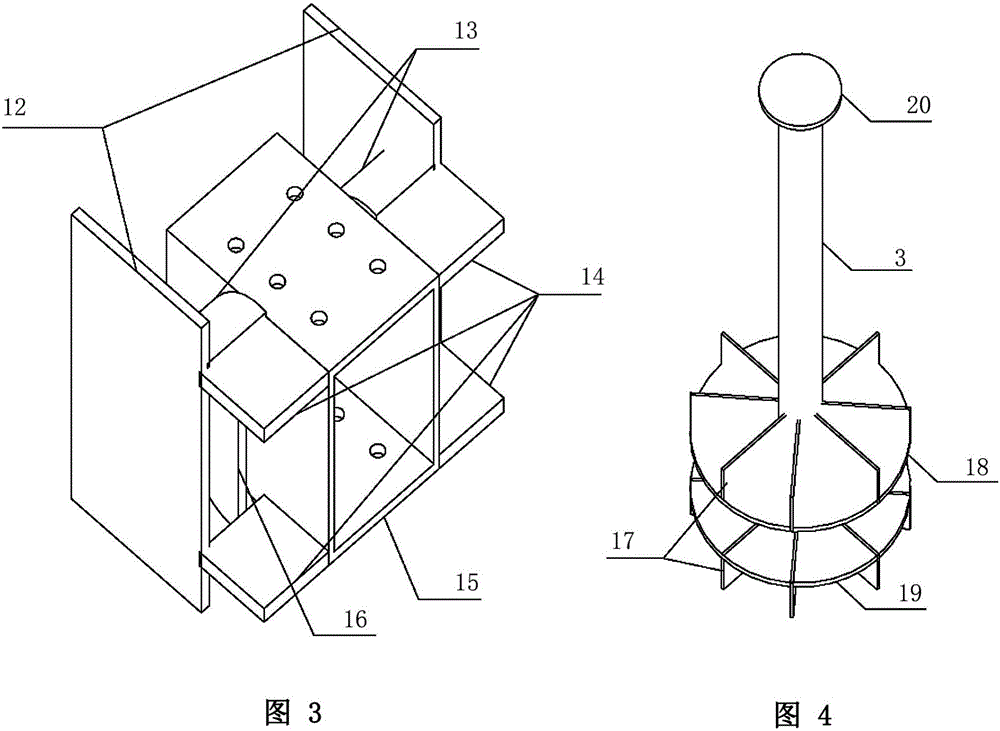

[0034] Exemplary embodiments of the present invention will now be described in detail, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like parts. The embodiments are described below in order to explain the present invention by referring to the figures.

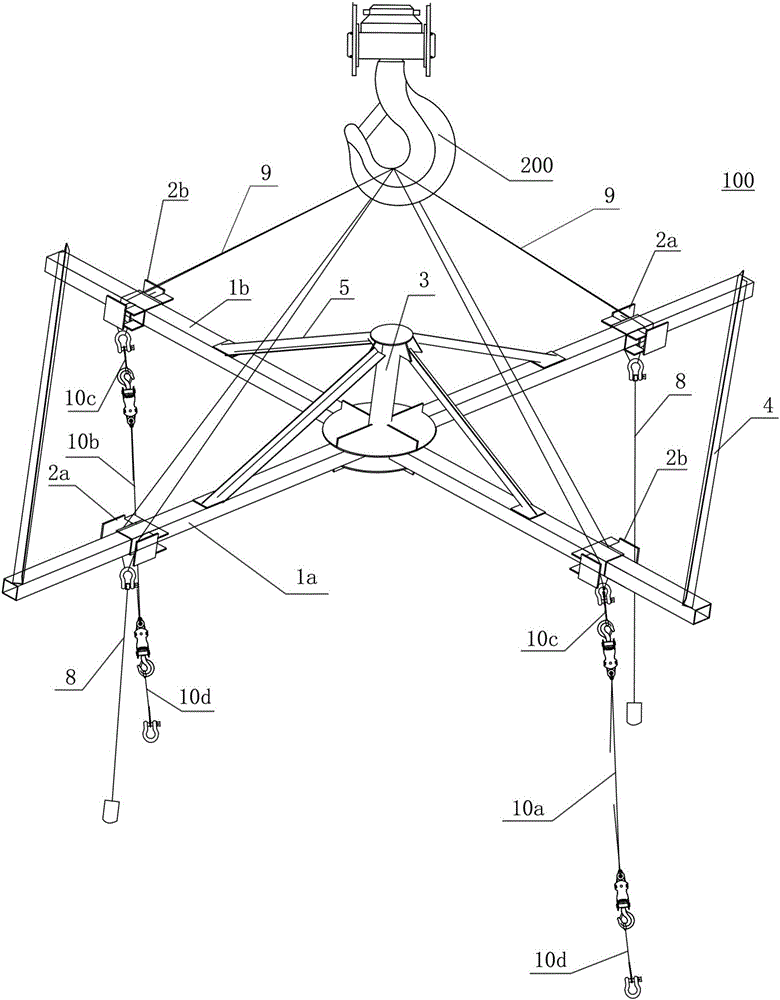

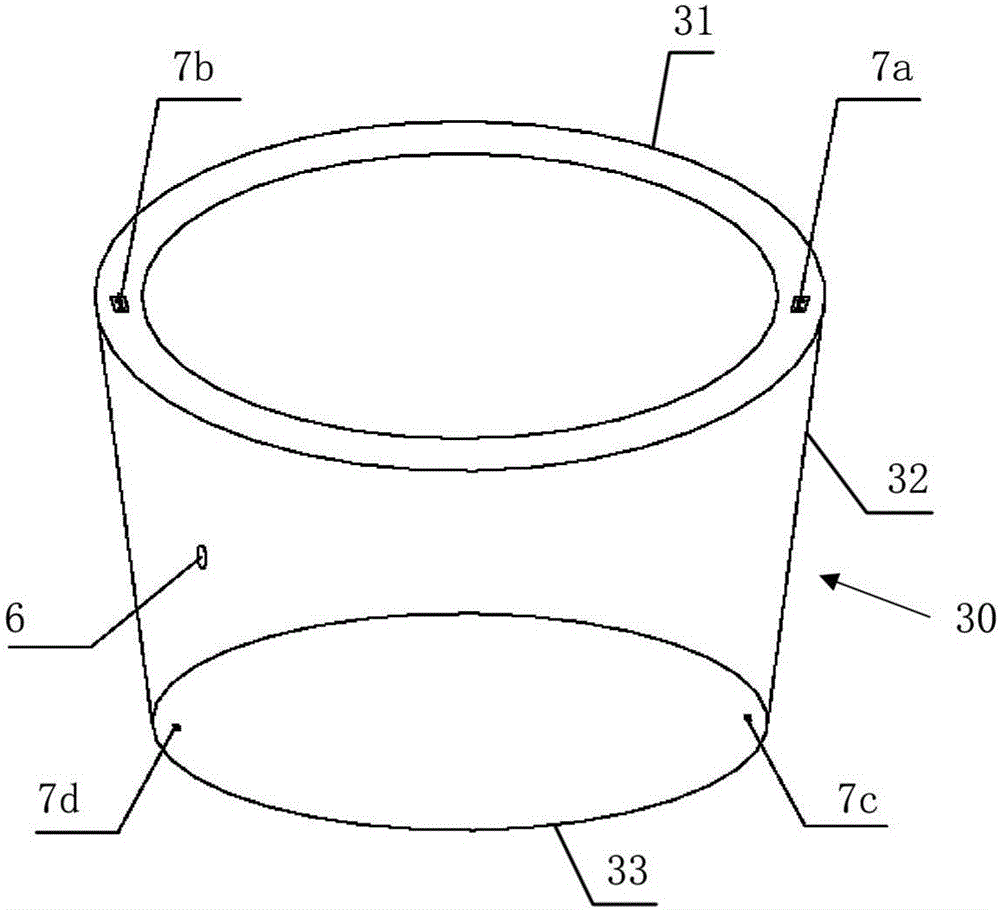

[0035] figure 1 is a perspective view showing the hoisting frame main body 100 of the hoisting turning device for a concrete tower 30 according to the embodiment. figure 2 is a perspective view showing a precast concrete tower 30 according to the embodiment.

[0036] The hoisting turning device for a concrete tower 30 according to the embodiment includes a hoisting frame body 100 , a pair of tower slings 8 , a first inverted chain 10 a and a second inverted chain 10 b.

[0037] In addition, an upper suspension point for connecting with a hook of a lifting device is provided on an upper portion of the upper surface of the lifting frame main body 100 . Four lower susp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com