A kind of ceramic carbon resistance and preparation method thereof

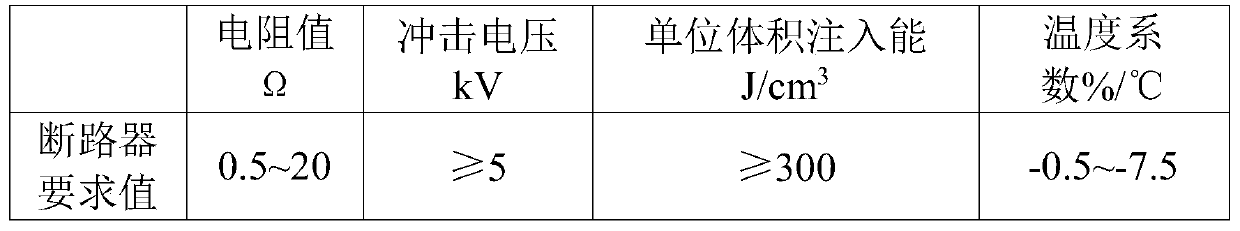

A technology of carbon resistors and ceramics, which is applied in the field of ceramic carbon resistors and its preparation, can solve the problems of difficult control of the chemical composition of bauxite, large resistivity dispersion, and endangering human health, and achieve easy control and small resistivity dispersion , high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The ceramic carbon resistance of the present invention is made of 30 parts by mass of corundum, 20 parts of mullite, 5 parts of quartz sand, 10 parts of glass powder, 15 parts of organic carbon and 0.5 part of binder Prepared.

[0024] The binder is diatomite; the organic carbon is epoxy resin; the particle size of corundum is 80-500 mesh; the particle size of mullite is 80-500 mesh; the particle size of quartz sand is 100-400 mesh.

[0025] The preparation method of ceramic carbon resistance of the present invention comprises the following steps:

[0026] 1) Weigh corundum, mullite, quartz sand, glass powder, organic carbon and binder, and then mix corundum, mullite, glass powder and quartz sand to obtain mixture A;

[0027] 2) ball milling the mixture A obtained in step 1), adding organic carbon, and then adding a binder after ball milling to obtain mixture B;

[0028] 3) adding pure water to the mixture B obtained in step 3) and then performing pulping to obtain a ...

Embodiment 2

[0035] The ceramic carbon resistance of the present invention is made of 40 parts by mass of corundum, 32 parts of mullite, 10 parts of quartz sand, 15 parts of glass powder, 8 parts of organic carbon and 1 part of binder Prepared.

[0036] The binder is phenolic resin; the organic carbon is pitch; the particle size of corundum is 80-500 mesh; the particle size of mullite is 80-500 mesh; the particle size of quartz sand is 100-400 mesh.

[0037] The preparation method of ceramic carbon resistance of the present invention comprises the following steps:

[0038] 1) Weigh corundum, mullite, quartz sand, glass powder, organic carbon and binder, and then mix corundum, mullite, glass powder and quartz sand to obtain mixture A;

[0039] 2) ball milling the mixture A obtained in step 1), adding organic carbon, and then adding a binder after ball milling to obtain mixture B;

[0040] 3) adding pure water to the mixture B obtained in step 3) and then performing pulping to obtain a slu...

Embodiment 3

[0047] The ceramic carbon resistance of the present invention is by mass parts 75 parts of corundum, 45 parts of mullite, 15 parts of quartz sand, 30 parts of glass powder, 3 parts of organic carbon and 2 parts of binder Prepared.

[0048] The binder is glass powder; the organic carbon is an organic polymer; the particle size of the corundum is 80-500 mesh; the particle size of the mullite is 80-500 mesh; the particle size of the quartz sand is 100-400 mesh.

[0049] The preparation method of ceramic carbon resistance of the present invention comprises the following steps:

[0050] 1) Weigh corundum, mullite, quartz sand, glass powder, organic carbon and binder, and then mix corundum, mullite, glass powder and quartz sand to obtain mixture A;

[0051] 2) ball milling the mixture A obtained in step 1), adding organic carbon, and then adding a binder after ball milling to obtain mixture B;

[0052] 3) adding pure water to the mixture B obtained in step 3) and then performing pul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com