Activated dye ink as well as preparation method and application thereof

A reactive dye and ink technology, applied in the application, dyeing, ink and other directions, can solve the problems of not enough bright colors, poor batch reproducibility, unclear images, etc., to improve the clarity and color reproduction, improve quality, Reduce the effect of line burrs

Inactive Publication Date: 2017-04-26

SHANGHAI ANNUOQI DIGITAL TECH CO LTD +2

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] The technical problem solved by the present invention is to overcome the defects of the existing traditional reactive digital printing inks in the wet printing process, s

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

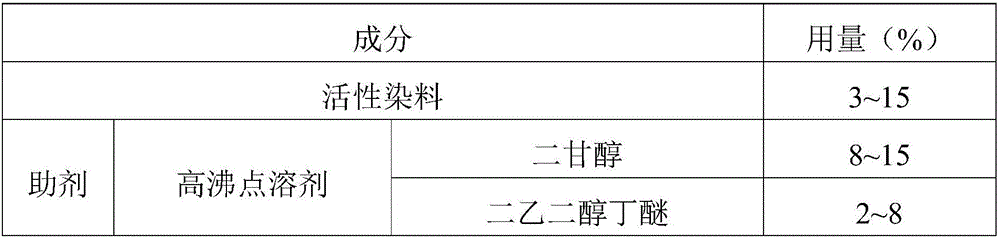

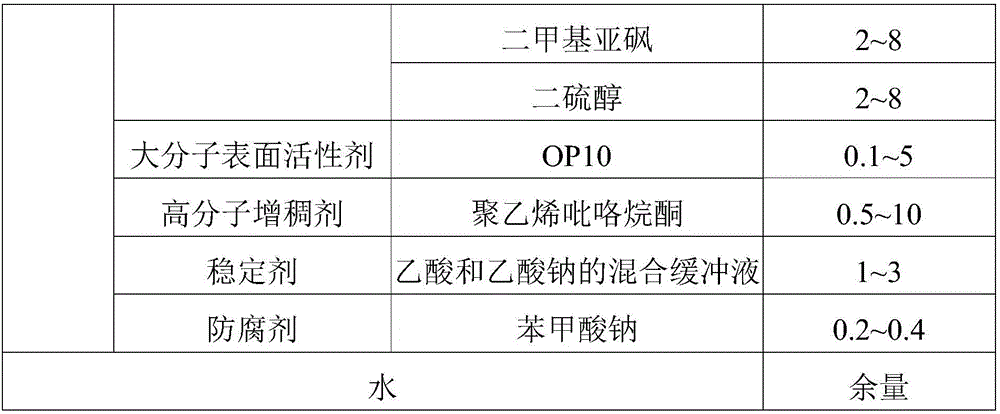

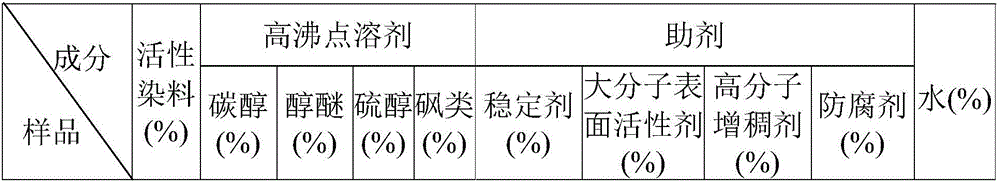

The invention discloses activated dye ink as well as a preparation method and application thereof. The activated dye ink comprises an activated dye, an adjuvant, a high-boiling-point solvent and water, wherein the adjuvant comprises a macromolecular thickener and a macromolecular surfactant with the molecular weight of 500 to 2,000; the use amount of the macromolecular surfactant is 0.1 to 5 percent, the use amount of the macromolecular thickener is 0.3 to 10 percent, the use amount of the activated dye is 3 to 15 percent, and the use amount of the high-boiling-point solvent is less than 25 percent but not 0; and the percentage is a percentage of the mass of each component in the total mass of the activated dye ink. The preparation method comprises mixing all the components and filtering the mixture. The activated dye ink disclosed by the invention is applied to a wet-printing digital printing technology, so that the phenomena of lines and burrs of wet-printing digital printing can be greatly reduced, the brightness of a textile, the clearness of a pattern and the color stability of textiles subjected to batch printing and dyeing are improved, and the problem of print permeability of a thick textile is effectively solved.

Description

technical field [0001] The invention relates to the field of digital inkjet printing, in particular to a reactive dye ink and its preparation method and application. Background technique [0002] Digital printing technology is an emerging green printing technology that emerged in the 1990s. In small-batch textile printing, it has the characteristics of fast, high efficiency and low cost. It is a new textile printing technology vigorously advocated and supported by our country. As one of the industries supported by the state, textile digital inkjet printing technology has been widely promoted and used all over the world relying on its obvious green printing technology and unique printing method. [0003] The traditional textile digital inkjet reactive printing technology has been widely promoted and used in thin textiles such as silk, silk scarves, and mercerized cotton, but it is difficult to obtain market approval for thick textiles, such as thick towels, bath towels, and b...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D11/328C09D11/30D06P1/38D06P5/30D06P1/52D06P1/613D06P1/653

CPCC09D11/328C09D11/30D06P1/38D06P1/5242D06P1/6135D06P1/6138D06P1/6536D06P5/30

Inventor 葛惠德王吉祥李慧

Owner SHANGHAI ANNUOQI DIGITAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com