Portable stage

A portable, stage technology, applied in theaters, buildings, building structures, etc., can solve the problems of inconvenient transportation, occupy a large space, fixed volume, etc., to save transportation space and transportation costs, reduce volume, and reduce distance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

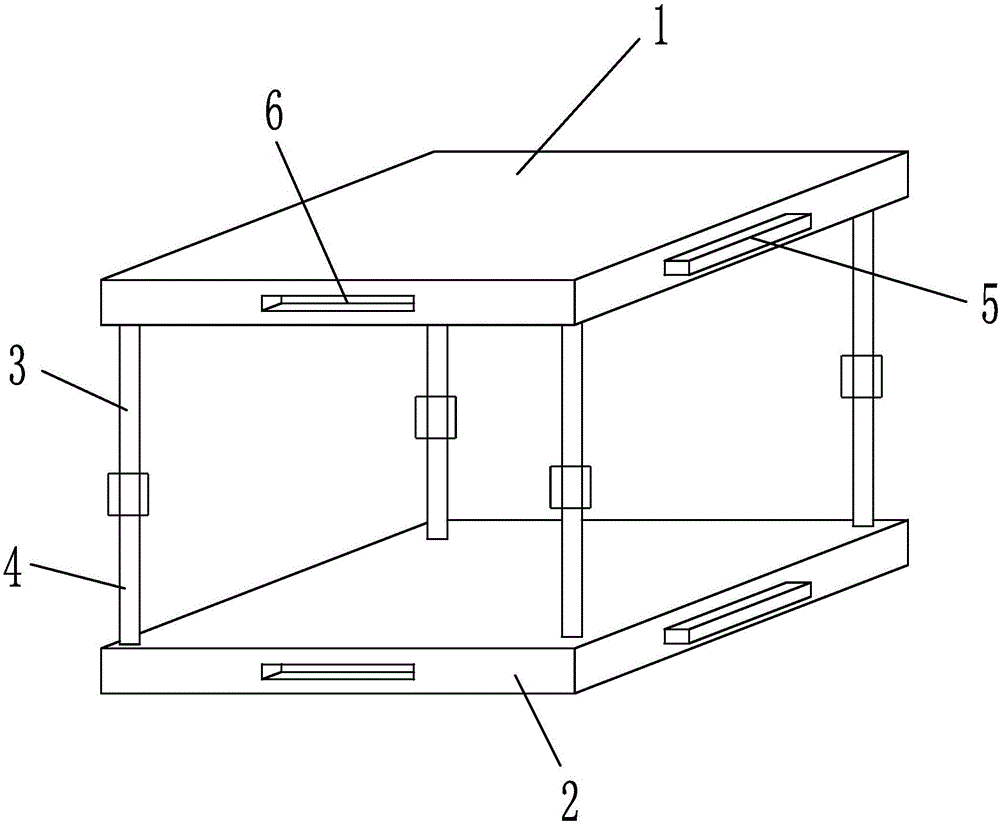

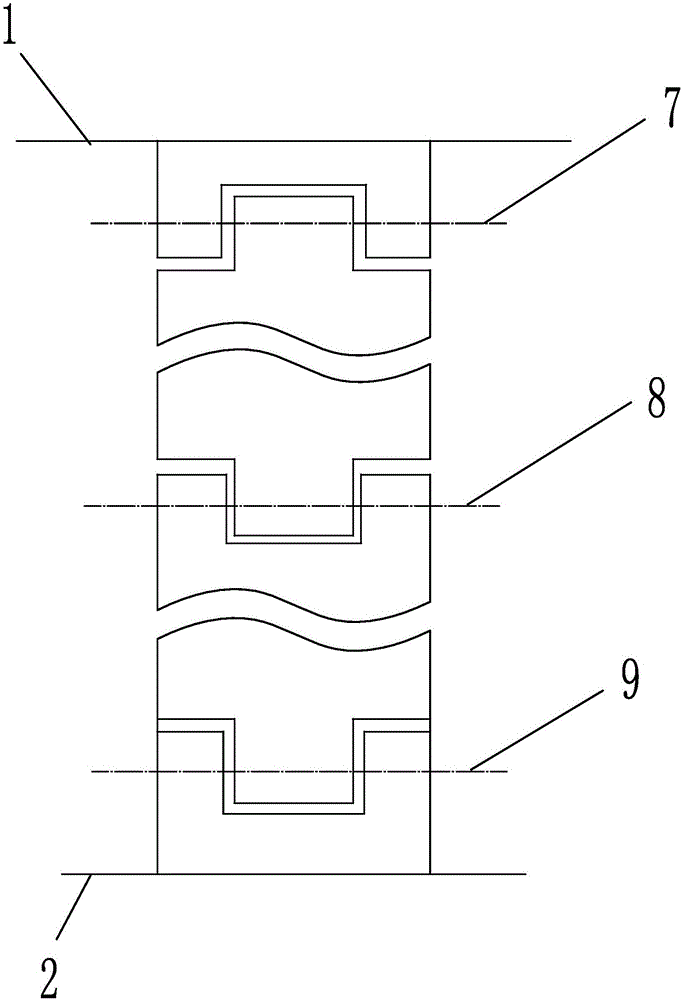

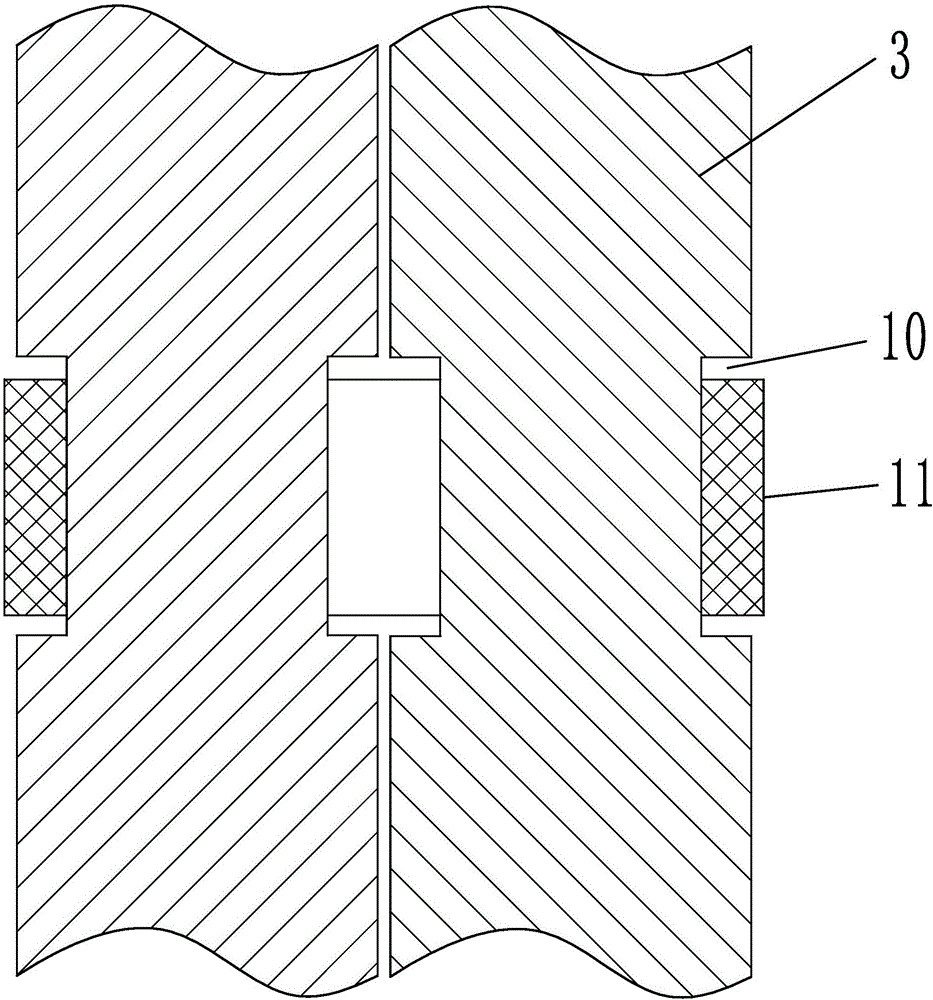

[0023] Embodiment 1: as figure 1 , 2 As shown in , 5, a portable stage includes a stage body, the stage body includes several stage base blocks spliced with each other, the stage base block includes an upper base plate 1 and a lower base plate 2, the opposite sides of the upper base plate are parallel to each other, and the One of the sides or two adjacent sides is provided with a limit protrusion 5, and the other three sides or two adjacent sides are provided with a limit protrusion to cooperate with another upper substrate of the same structure. The limit groove 6 of the upper base plate and the lower base plate have the same structure, and the corners of the upper base plate are provided with connecting arms, and the upper base plate is connected with the lower base plate through the connecting arms; the connecting arms include an upper support arm 3 and a lower support arm 4 , the upper support arm and the lower support arm are hinged through the first hinge mechanism 7...

Embodiment 2

[0025] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 8 As shown, the connecting plate comprises a left connecting plate 27 and a right connecting plate 28, several upper latches 29 are arranged on the left connecting plate, several lower latches 30 are arranged on the right connecting plate, the left connecting plate and the right connecting plate pass through The matching snap connection of the upper latch and the lower latch. One end of the hoop plate is the left connecting plate, and the other end is the right connecting plate, and the left and right connecting plates are just a relative concept of one left and one right. There are several upper teeth on the left connecting plate, and several lower teeth on the right connecting plate. When the hoop plate surrounds the connecting arm, match the upper and lower teeth on the left connecting plate and the right connecting plate. Insertion, mutua...

Embodiment 3

[0026] Embodiment 3: The structure of this embodiment is basically the same as that of Embodiment 1 or 2, the difference is that, as Figure 9 As shown, the two adjacent sides of the upper substrate are provided with outwardly protruding curved protrusions, and the other two adjacent sides are provided with outer edges of the curved protrusions of the upper substrate with the same structure. The limiting recess; the limiting protrusion is located in the middle of the height direction of the outer edge of the convex portion of the curved surface, and the limiting groove is located in the middle of the height direction of the limiting recess. The curved surface convex portion 31 on the upper substrate cooperates with the limiting concave portion 32 of the adjacent upper substrate, the limiting concave portion can limit the curved surface convex portion, the friction between the limiting concave portion and the curved surface convex portion is along the tangential direction, Sinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com