Automatic steel fireproof roller shutter

A fire-resistant roller shutter and steel technology, which is applied to fire-proof doors, shutters/movable grilles, door/window protection devices, etc., can solve the problems of easy deformation and damage of steel roller shutters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

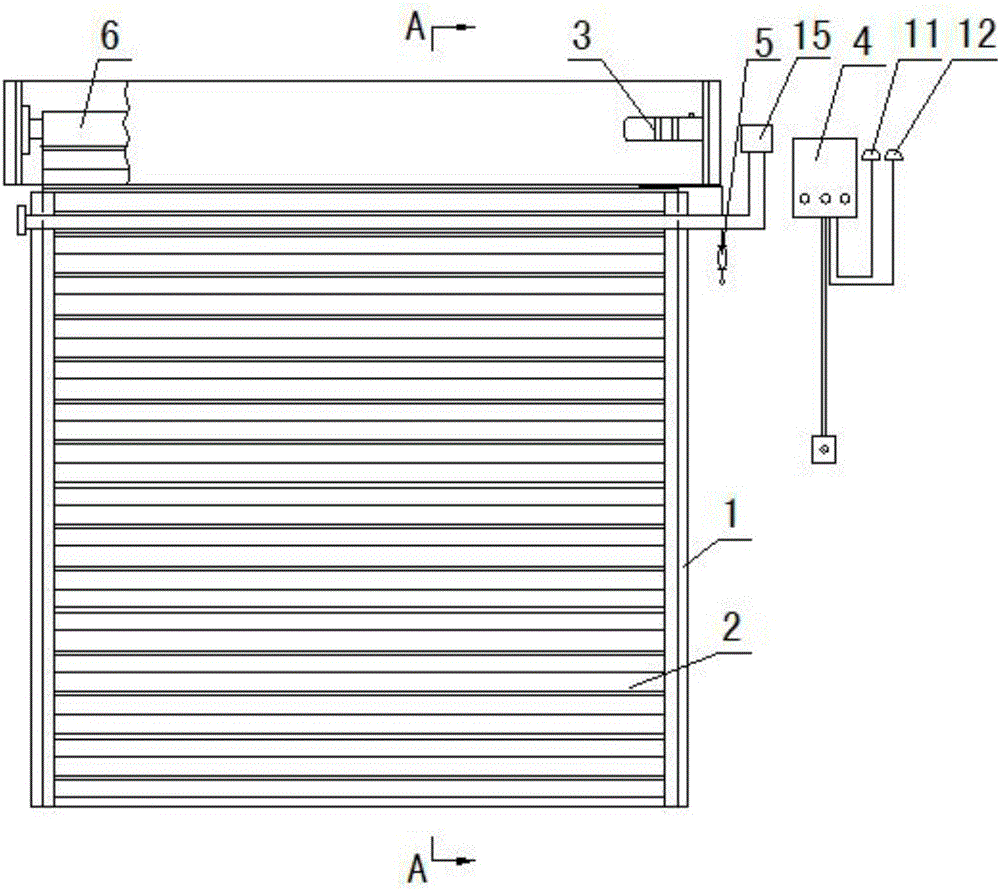

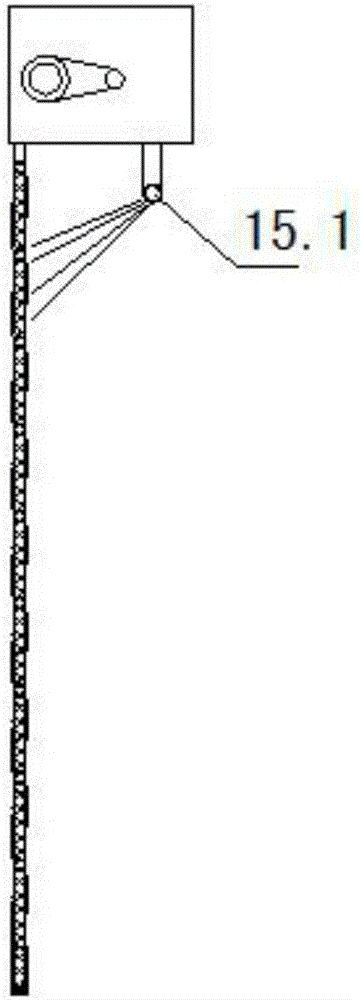

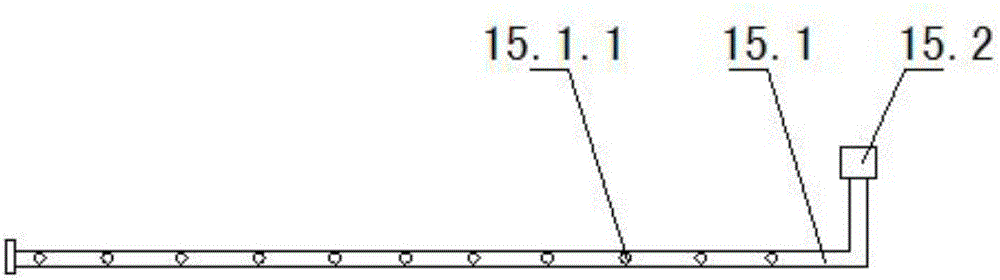

[0016] The automatic steel fire-proof rolling shutter shown in the accompanying drawings includes guide rail 1, curtain plate 2, door rolling machine 3, rolling shutter controller 4, reel 6, sprinkler system 15, point-type photoelectric smoke detector 11, temperature control Release device 5, point-type temperature-sensitive fire detector 12; the curtain panels 2 are connected in series to form a door curtain, which is installed in the fixed guide rail 1; the upper end of the door curtain is connected with the flat reel 6, and rotates around the central axis of the reel 6 to open and close up and down; spray The system 15 includes a spray pipe 15.1, a solenoid valve 15.2, and the solenoid valve 15.2 is electrically connected to the roller shutter controller 4; the spray pipe 15.1 is placed horizontally (in other embodiments, the spray pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com