Wafer fork, silicon wafer transfer device and method

A handover device and chip fork technology, which is used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as deformation and damage of silicon wafers, achieve good adsorption effect, improve transmission efficiency, product accuracy, and accurate handover positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

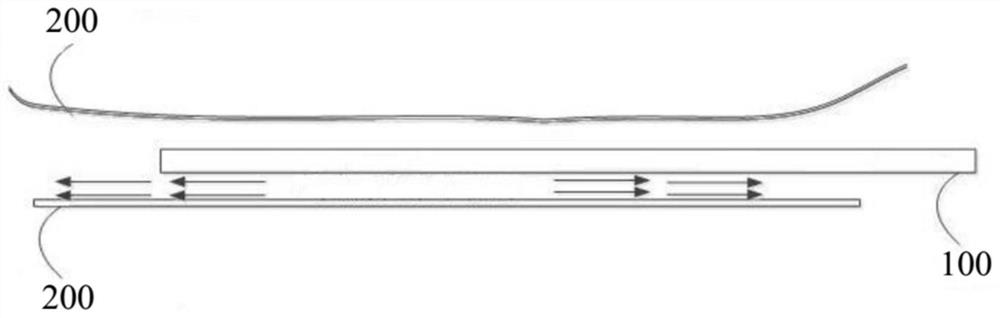

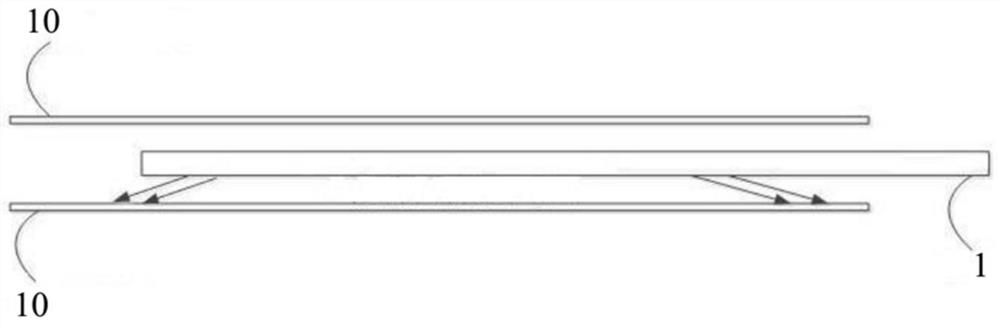

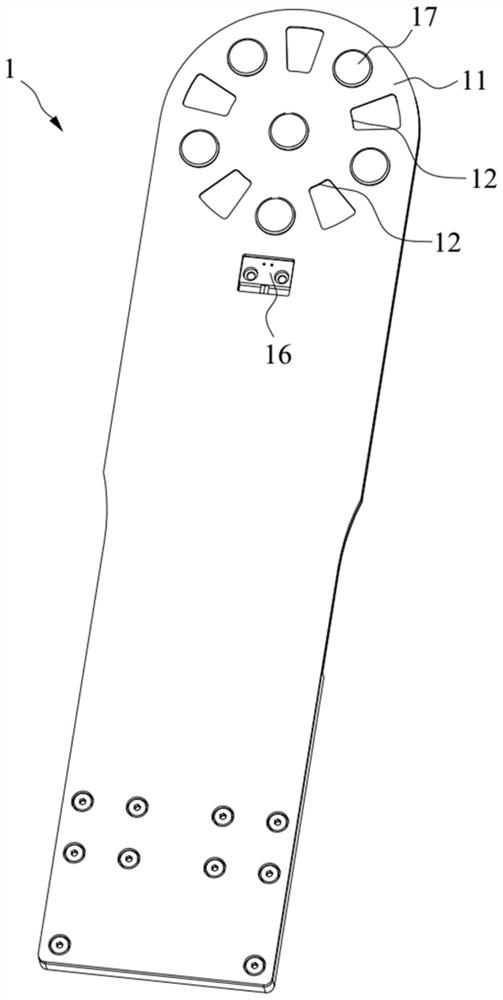

[0052] see figure 2 and image 3 , the embodiment of the present invention provides a fork for absorbing silicon wafer 10 . The chip fork 1 includes a chip fork body, and the chip fork body has an adsorption surface 11 for absorbing the silicon wafer 10. The adsorption surface 11 is provided with a plurality of air outlet holes 12, and the gas ejected from the plurality of air outlet holes 12 is inclined toward the outside of the adsorption surface 11. In order to reduce the air pressure on the adsorption surface 11, the Bernoulli effect is used to form a positive pressure adsorption area to adsorb the silicon wafer 10. Since the jetting direction of the gas is inclined, when the silicon wafer 10 in a certain groove is adsorbed, the silicon wafer 10 in an adjacent groove will not be deformed and damaged. Arrows in the drawings show the direction of gas flow.

[0053] Since the silicon wafer 10 is mostly circular, the adsorption surface 11 has a central position, and a plur...

Embodiment 2

[0078] Figure 10 to Figure 13 Embodiment 2 is shown, in which components identical or corresponding to those in Embodiment 1 are identified with reference numerals corresponding to Embodiment 1. For simplicity, only the differences between Embodiment 2 and Embodiment 1 are described. The difference is that the slope 14 is connected to the adsorption surface 11 and is located downstream of the gas outlet 12 , and the gas flows from the gas path 13 to the gas outlet 12 along the slope 14 . The structure of the air passage 13 and the air outlet 12 is simplified, which is convenient for processing and production.

[0079] In this embodiment, the extension direction of the air passage 13 is parallel to the adsorption surface 11, and the gas injection direction of the air outlet hole 12 is parallel to the adsorption surface 11. Due to the setting of the inclined surface 14, the gas ejected from the air outlet hole 12 is inclined relative to the adsorption surface 11. flow. exist...

Embodiment 3

[0084] For simplicity, only the differences between Embodiment 3 and Embodiment 1 are described. The difference is that along the direction of gas flow, the flow area of the gas path 13 decreases gradually, so that the gas flow speed is accelerated, and a stronger Bernoulli effect is formed on the adsorption surface 11, which is more conducive to stably adsorbing the silicon wafer 10 .

[0085] In Embodiment 1, when the inclined surface 14 is located at the intersection of the air passage 13 and the air outlet 12 , due to the setting of the inclined surface 14 , the cross-sectional shape of the air passage 13 changes from a rectangle to a triangle, and the flow area gradually decreases. Using the slope not only makes the injection direction of the gas inclined, but when the silicon wafer in a certain groove is adsorbed, it will not cause deformation and damage to the silicon wafer in the adjacent groove; and the flow area of the gas path 13 is gradually reduced, and the flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com