Filling type hollow hydraulic support device

A hydraulic prop and filling technology, which is applied in the directions of props/supports, mining equipment, earth cube drilling, etc., can solve problems such as poor safety, difficult manufacturing and maintenance, and complicated friction clamping mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below through preferred embodiments in conjunction with the accompanying drawings.

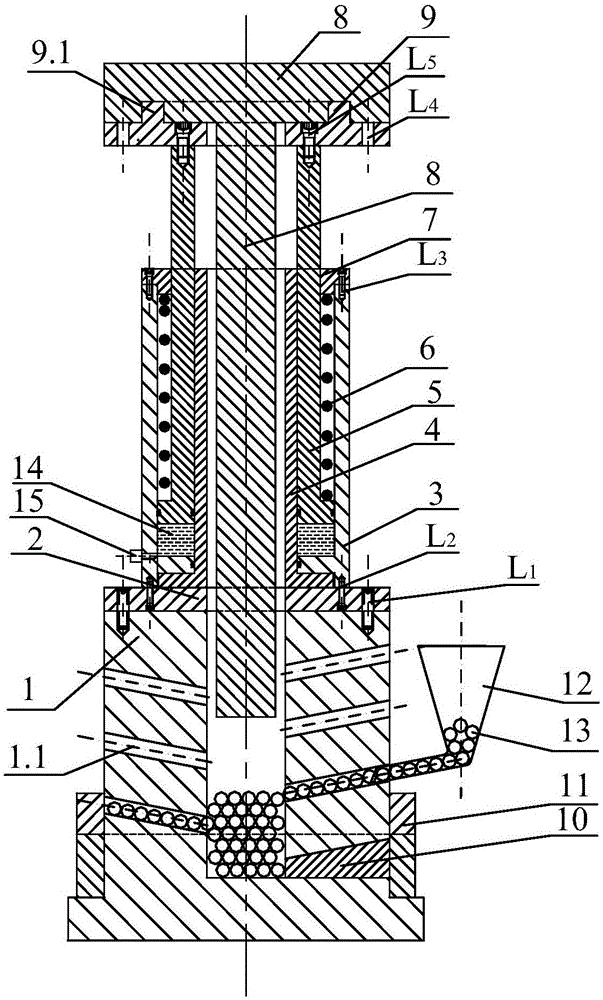

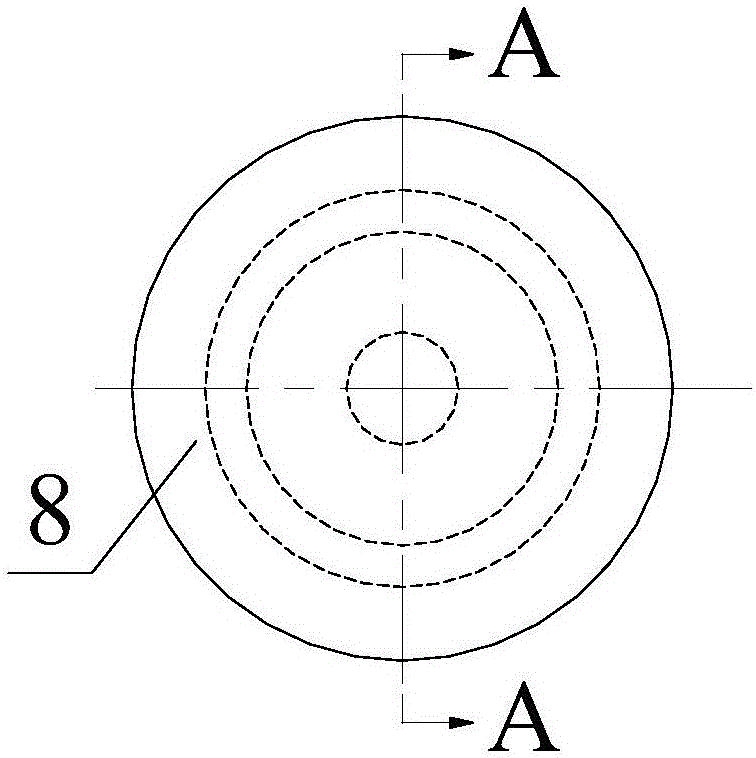

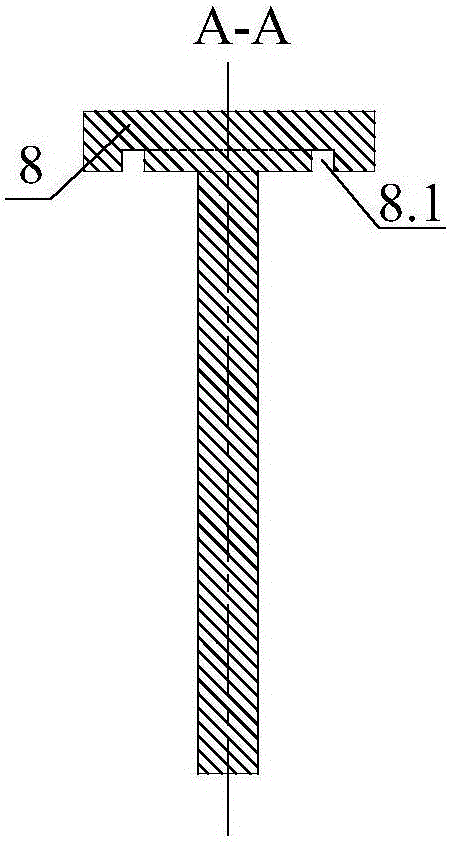

[0018] Such as figure 1 As shown, the device of the present invention is transported in the tunnel, a general-purpose liquid injection gun is inserted into the liquid injection hole of the three-purpose valve 15, the liquid injection gun is opened, and the high-pressure liquid is driven by the hydraulic pump to the one-way valve in the three-purpose valve. Push the steel ball into the hydraulic chamber to raise the piston 5; when the upper end of the "T"-shaped top cover 8 is close to the working surface, the liquid injection gun stops operating, and the pressure of the emulsion 14 in the hydraulic chamber is the pump station pressure. , the "T"-shaped top cover 8 has obtained the initial supporting force; according to the height of the rising column, move the ring sleeve 11, connect the special tool funnel 12 with the ramp 1.1, and put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com