Air tightness test device

A test device and air-tightness technology, which can be used in the use of liquid/vacuum for liquid-tightness measurement, and by detecting the appearance of fluid at the leak point, which can solve problems such as poor controllability, low safety, and easy occurrence of safety accidents. , to achieve the effect of stable parts, good controllability, and prevention of dangerous accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

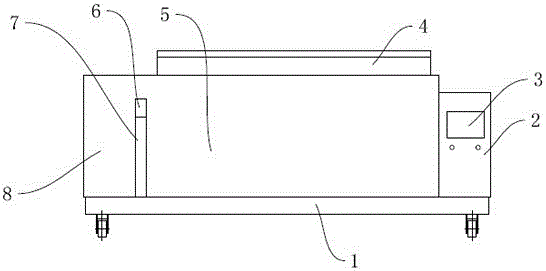

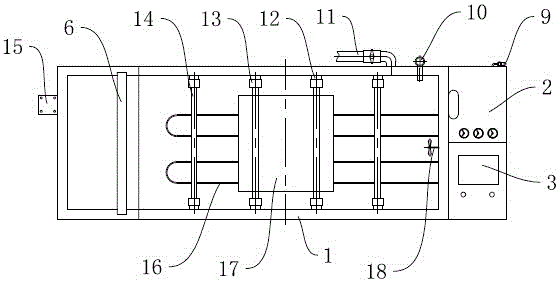

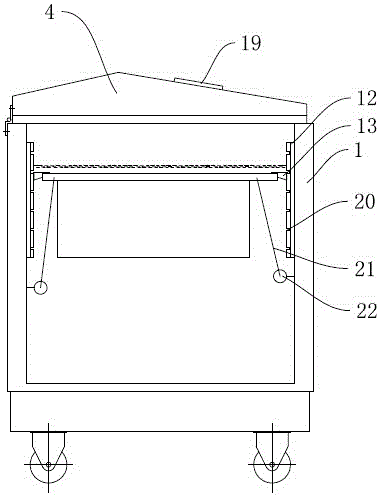

[0025] Embodiment: a kind of air tightness test device (referring to figure 1 figure 2 image 3 ), including the water tank 1 and the inflation device of the connecting parts 17, the inside of the water tank is provided with a pressure covering part 14 for pressing parts, the upper part of the water tank is hinged with an openable safety tank cover 4, and the safety tank cover is connected to the water tank. 15. Drive the safety box cover to rotate through the cylinder. The section of the safety case cover is triangular in shape, and the inclined surface of the safety case cover is provided with an observation window, and a transparent plate 19 is fixed on the observation window. A control cabinet 2 is connected to the side of the water tank, and the control cabinet has a display screen 3 .

[0026] A reference partition 7 is arranged inside the water tank, and the reference partition divides the water tank into two parts, one part is the immersion area 5 where the pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com