Drawing radome opening mechanism

A technology of opening mechanism and radome, which is applied in the direction of antenna, antenna parts, radiation unit cover, etc., which can solve the problems of high precision and increased weight of fixed right-angle slide rails and cylinder heads, so as to reduce the structural weight and ensure the position The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution will be described in further detail below in conjunction with the accompanying drawings.

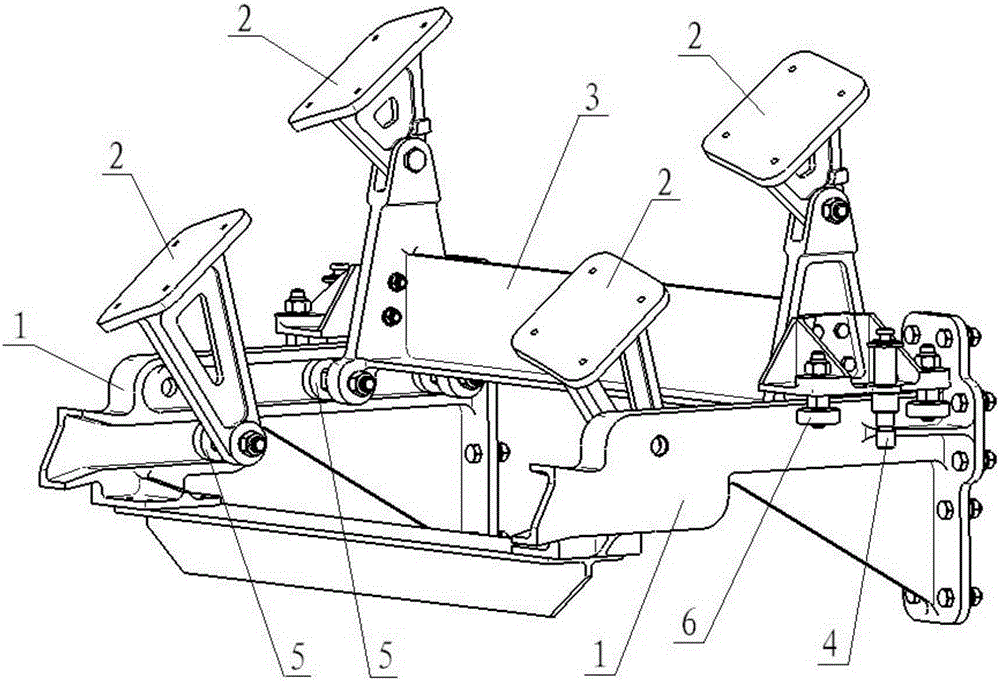

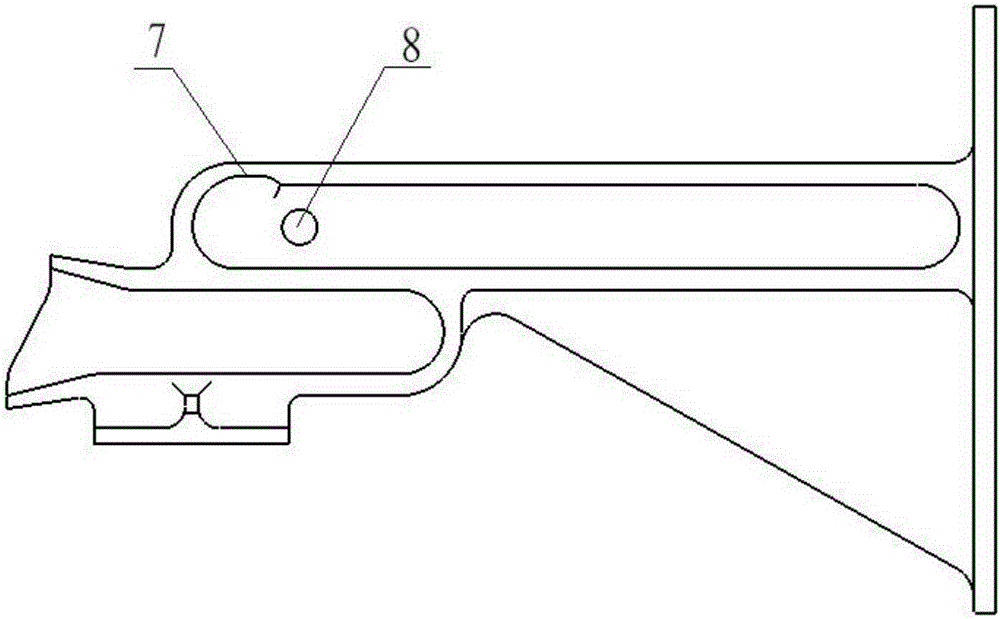

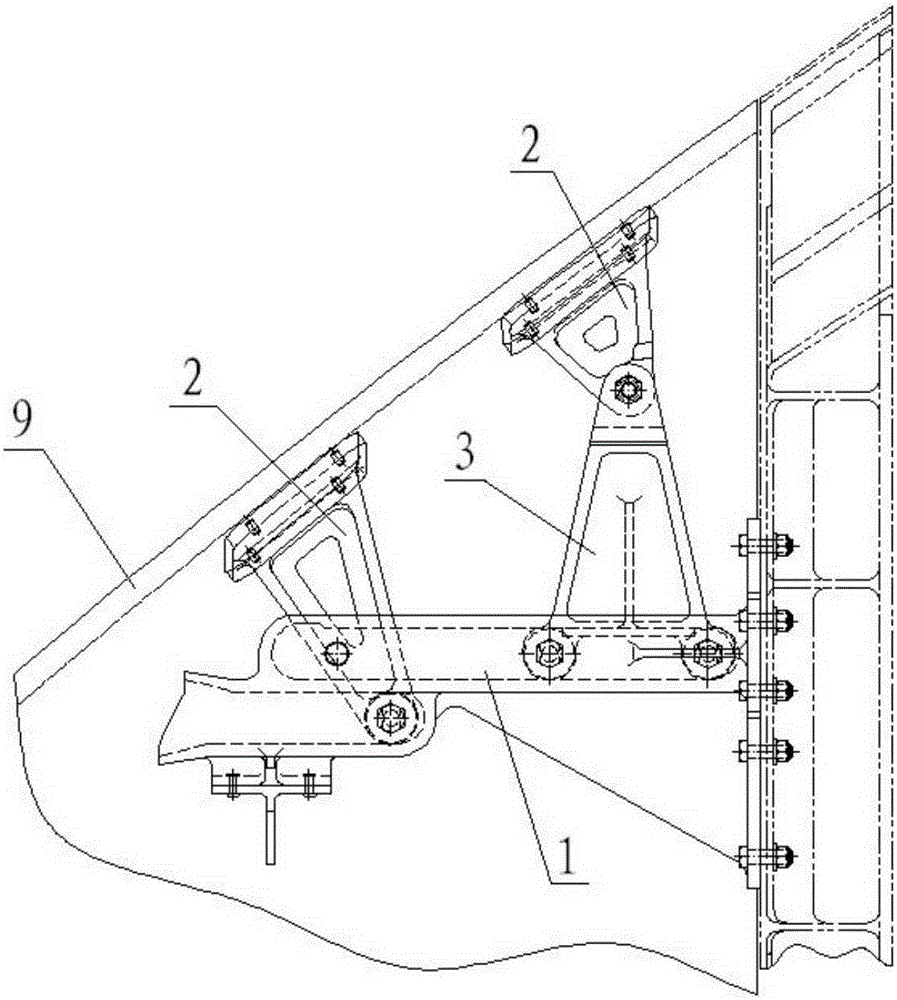

[0015] As shown in the figure, the opening mechanism includes a double-layer slide rail 1, an ear piece 2, a slider 3 and a roller 5. Two upper and lower tracks are distributed on one end surface of the double-layer slide rail 1, and the two ends of the slider 3 A roller 5 is installed, and the roller 5 is located in a track of the double-layer slide rail 1, and can slide in the track. Each end of the ear piece 2 is equipped with a roller 5, and the roller 5 on the ear piece 2 is located on the double-layer slide rail 1. In the other track, one end of the track where the roller 5 on the lug 2 is located is an opening;

[0016] The upper end of the slider 3 is hinged with an ear piece 2. When the radome cover body 9 is fixed on the ear piece 2 and the roller 5 on the slider 3 moves to one end of the track where it is located, the roller 5 on the ear piece 2 w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap