Multifunctional worktable for electric power maintenance

A technology for electrical maintenance and workbenches, applied in electrical components, switchgear and other directions, can solve the problems of inconvenience in carrying, complex disassembly and assembly, and single function, and achieve the effects of diverse functions, high operational safety and high convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

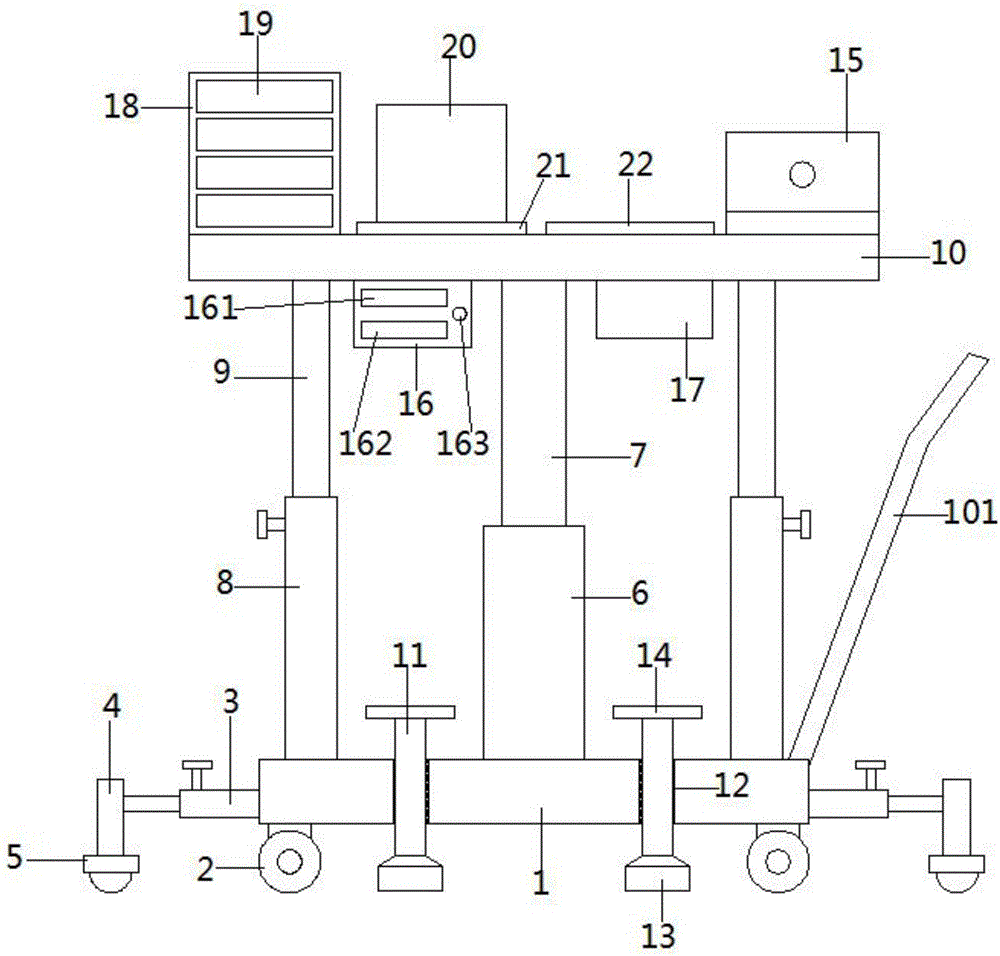

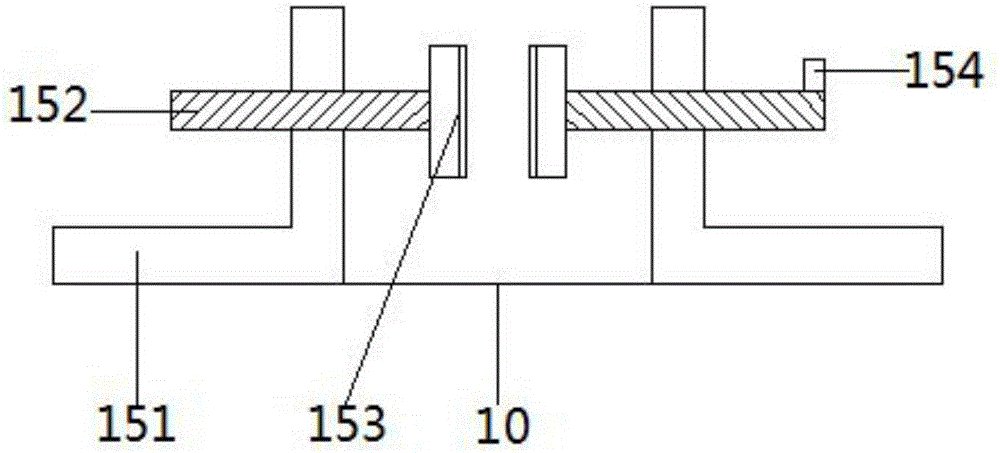

[0018] Example: see Figure 1-2 , in an embodiment of the present invention, a multifunctional workbench for electric power maintenance includes a base 1, and walking wheels 2 are provided around the lower side of the base 1, and horizontally arranged horizontal telescopic rods 3 are respectively connected to the four corners of the side of the base 1, The other end of the horizontal expansion rod 3 is also provided with a support 4, and the bottom end of the support 4 is also provided with a universal ball 5, and the center of the outer wall of the upper side of the base 1 is provided with an outer tube 6 extending vertically upwards. An inner pipe 7 is also embedded in the pipe 6, and the outer wall of the inner pipe 7 is threadedly connected with the inner wall of the outer pipe 6. At the four corners of the upper side of the base 1, there are vertical rods 8 extending vertically upward. The upper side of the vertical rod 8 is connected with the elevating rod 9, and the hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com