Plasma generator

A plasma and generator technology, applied in the field of ion generators, can solve the problems of unreliable installation of metal mesh, uneven discharge, easy offset, etc., and achieves the advantages of exciting discharge efficiency, ensuring discharge efficiency and reducing energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

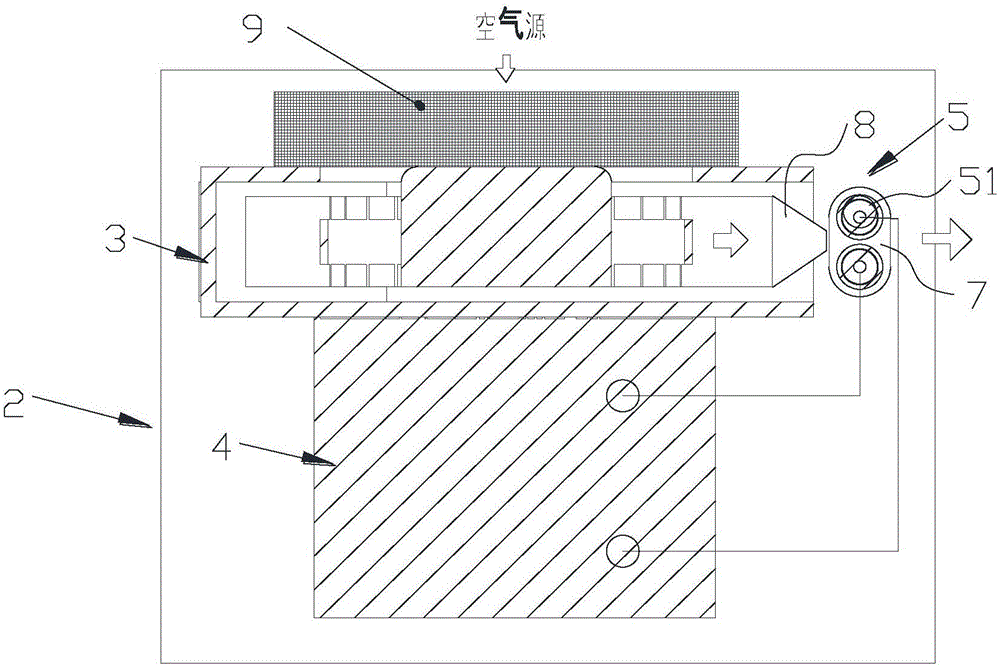

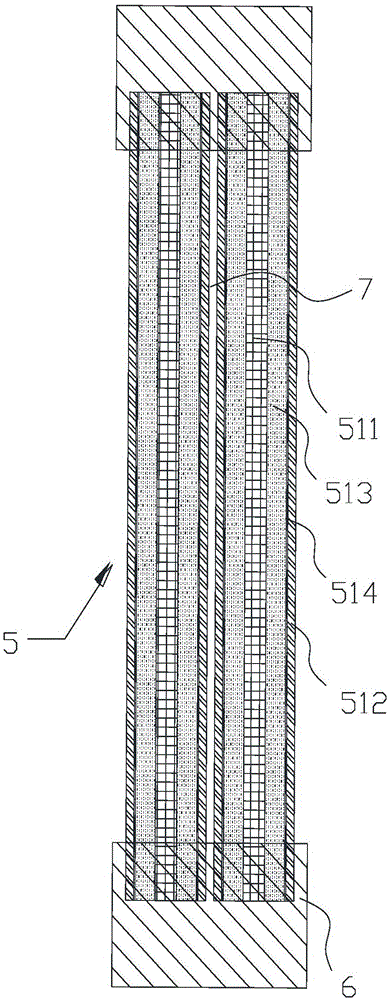

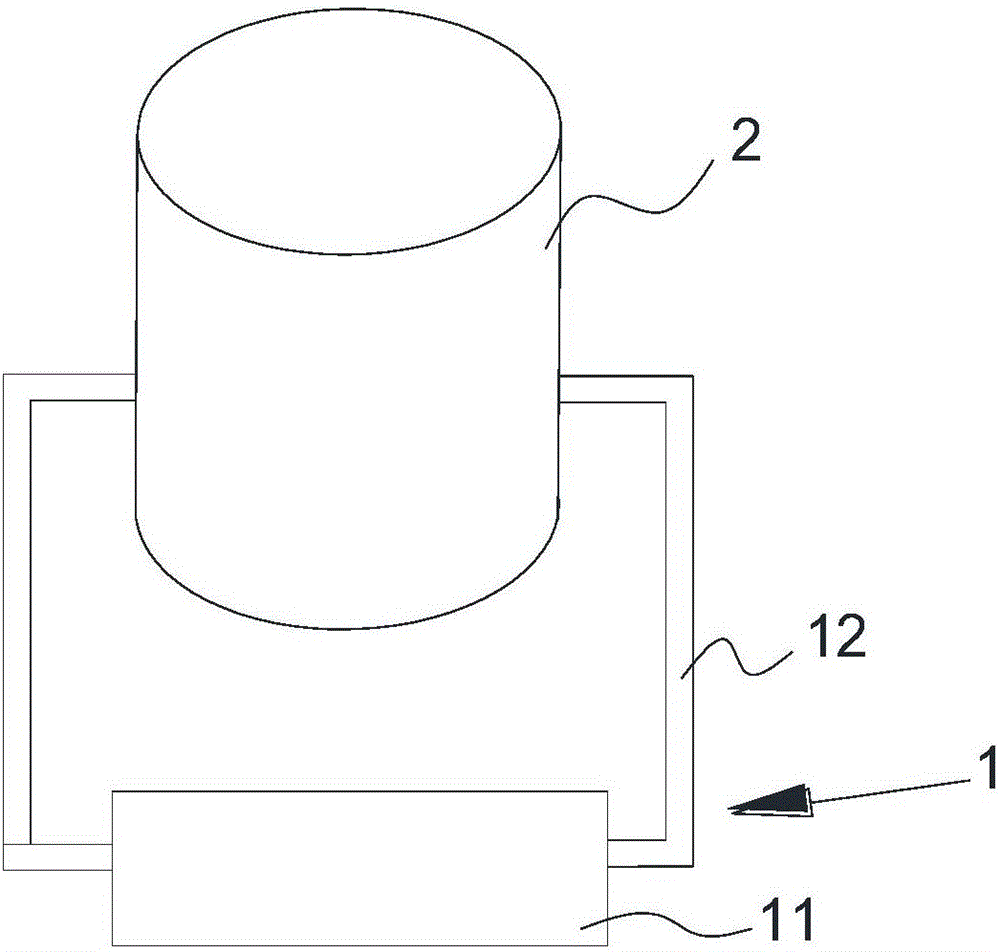

[0019] Such as Figure 1-3 As shown, the plasma generator includes a rotating frame 1, a housing 2 with an air inlet and an injection port, a vortex fan 3, a power supply 4, a discharge body 5 and an insulating sealing support 6 all installed in the housing 2 , the discharge body 5 includes two parallel and spaced discharge tubes 51, the discharge tube 51 includes an electrode 511 electrically connected to the power supply 4 through an electrode 511 wire, and a quartz tube 512 that is sleeved outside the electrode 511 at intervals, And the inert gas 513 filled in the quartz tube 512, the inner wall of the quartz tube 512 is coated with a fluorescent coating 514; a discharge gap 7 facing the injection port is formed between the two discharge tubes 51; The air outlet of the vortex fan 3 is equipped with a nozzle 8, and the opening of the nozzle 8 is faci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com