Die-casting die for new energy automobile brake booster oil cylinder and using method

A technology for new energy vehicles and die-casting molds, applied in the field of parts forming, can solve the problems of large machining allowance, high machining cost and low machining efficiency, and achieve the effects of reducing machining cost, improving efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

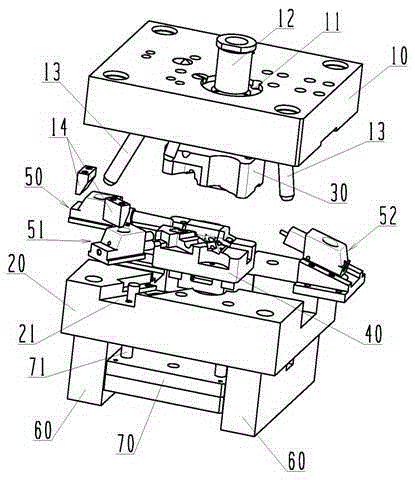

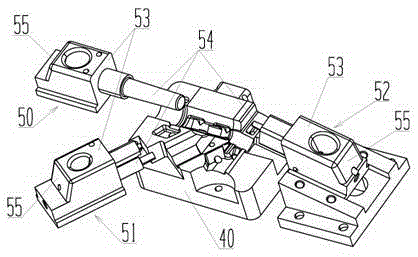

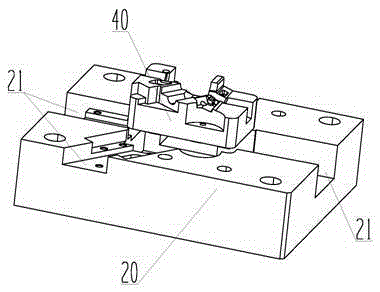

[0025] A die-casting mold for a brake booster cylinder of a new energy vehicle, comprising an upper template 10 and a lower template 20, an upper mold block 30 is detachably inlaid at the center of the lower surface of the upper template 10, and the center of the upper surface of the lower template 20 is The position is detachably inlaid with a lower mold block 40, the upper mold block 30 and the lower mold block 40 are both provided with a cavity, and the lower template 20 is also provided with three core-pulling mechanisms, which are respectively the first core-pulling mechanism 50. The second core-pulling mechanism 51 and the third core-pulling mechanism 53. The first core-pulling mechanism 50 is used to form the inner cavity on the cylinder of the brake booster. The second core-pulling mechanism 51 and the third core-pulling mechanism 52 are respectively use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com