Intelligent picking robot

A picking robot and intelligent technology, applied in horticulture, agriculture, plant cultivation, etc., can solve the problems of low efficiency, low degree of automation and low degree of intelligence in the mushroom transportation process, and achieve compact structure, high degree of automation and intelligence high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Referring to the accompanying drawings, the present invention will be further described in detail with specific embodiments.

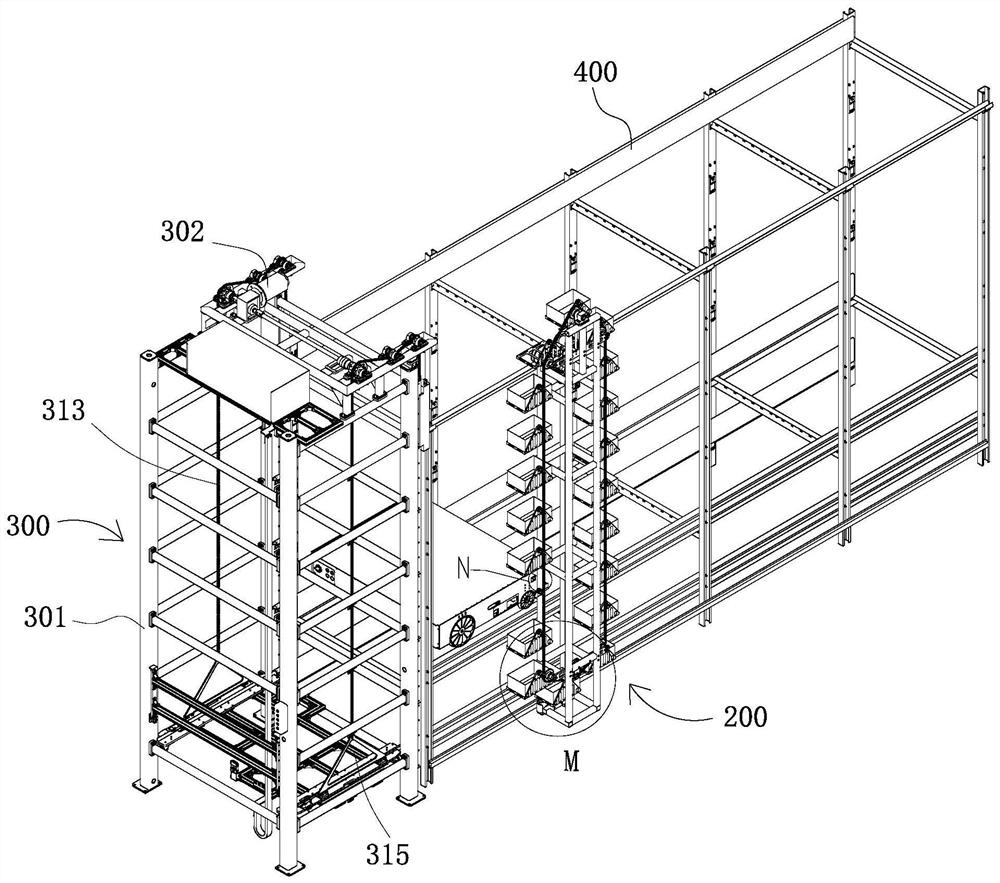

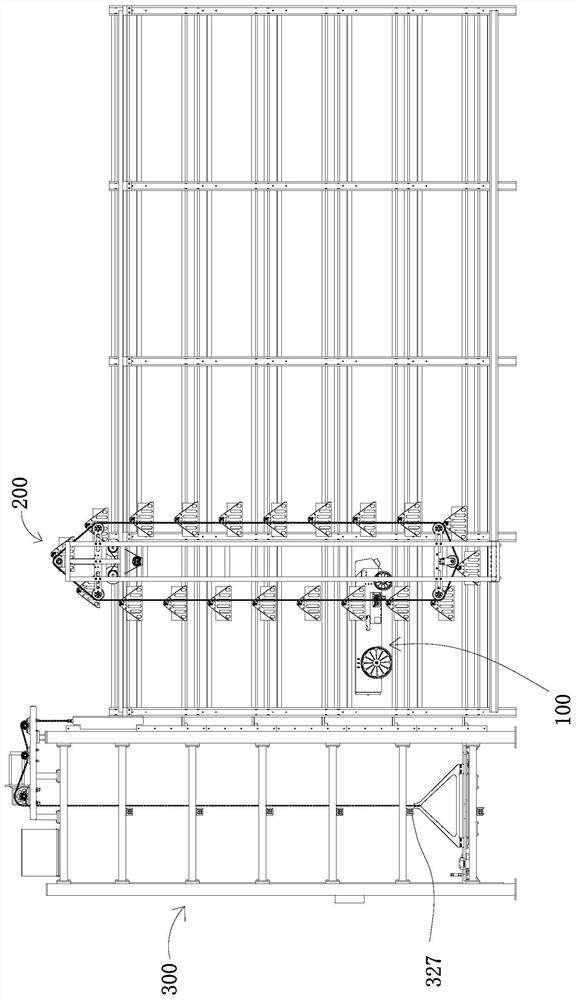

[0078] Such as Figure 1-6 As shown, the intelligent picking system includes an automatic picking robot 100 , an unattended material receiving device 200 , and an automatic layer changing device 300 .

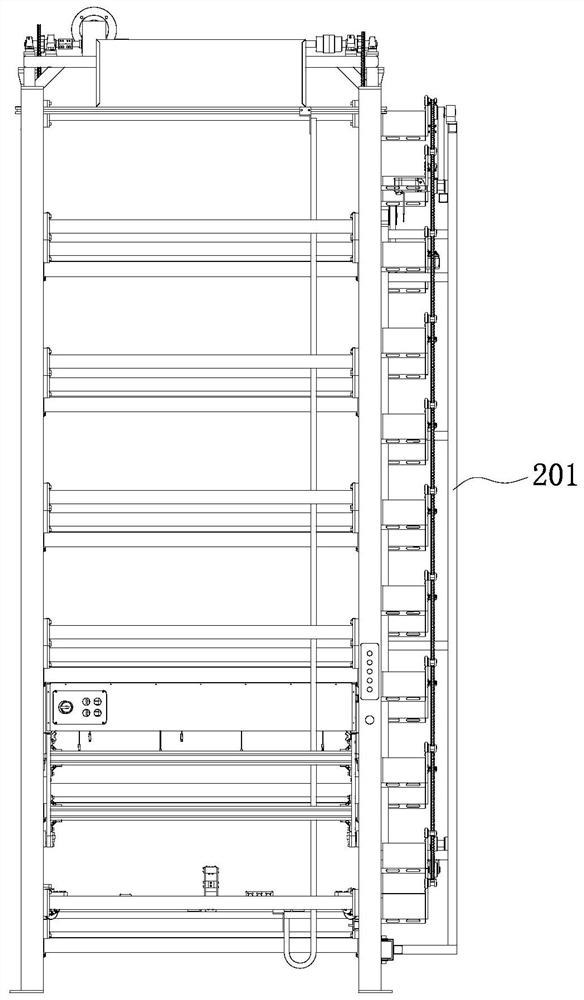

[0079] Such as Figure 10-18 As shown, the unattended material receiving device 200 includes a vertical support 201, a support wheel 202, a driving wheel 203, a first traveling wheel 204-1, a second traveling wheel 204-2, a circulation drive motor 205, a circulation chain 206, an upper Support plate 207, lower support plate 208, driving sprocket connection seat 209, circulation driving synchronous pulley 210, circulation synchronous belt 211, driving sprocket rotating shaft 212, driving sprocket 213, first driven sprocket 214, second driven sprocket Driven sprocket 215, the 3rd driven sprocket 216, the 4th driven sprocket 217, the 5th driven sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com