Precision forging machine locking cylinder buffer mechanism

A buffer mechanism and locking cylinder technology, applied in the field of precision forging machines, can solve the problems of inconsistent hammer head position, reduced life, reduced dimensional accuracy, etc., to eliminate the effect of uncertain clearance, reduce waste, and improve dimensional accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

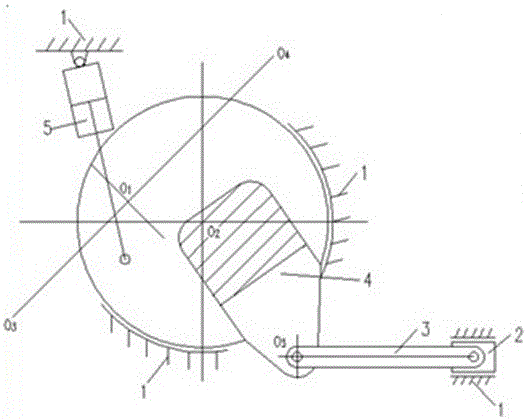

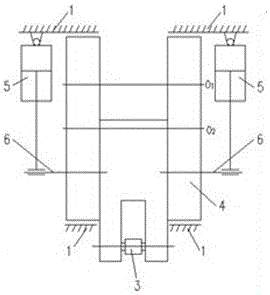

[0013] Such as figure 1 with figure 2 As shown, the eccentric sleeve adjusts the reduction amount of the hammer head of the precision forging machine. One end of the eccentric sleeve 4 is fixed at the rotation center O2 of the frame 1 of the precision forging machine, and the hammer head driven by the eccentric shaft is located at the non-rotation center of the frame. at O1.

[0014] The slider 2 is fixedly connected to one end of the pull rod 3, and the other end of the pull rod 3 is fixed to the outside of the eccentric sleeve 4, and the motor drives the slider 2 to move, thereby driving the eccentric sleeve 4 to rotate, and adjusting the hammer head depression.

[0015] There are gaps between the eccentric sleeve 4 and the frame 1, and the slide block 2 to its driving motor. Since there is no restriction, the direction of these gaps is uncertain. When not forging, the gravity makes the eccentric sleeve 4 sink, and the gap between it and the frame 1 is at the top. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com