Gas-assisted injection molding process for automobile interior trim

A gas-assisted technology for automotive interior parts, applied to household components, household appliances, and other household appliances, can solve problems such as whitening and bright marks, and achieve the effects of reducing bright marks, easy blowing, and reducing cooling cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples, but not as a limitation of the present invention.

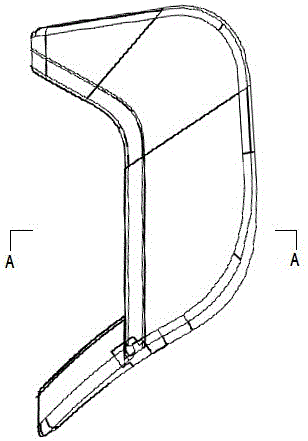

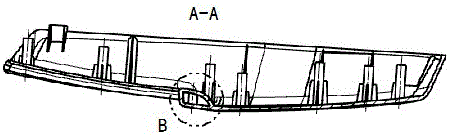

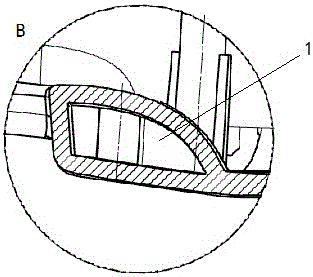

[0020] Taking the car map bag as an example, please combine Figure 1 to Figure 3 , the product is designed to have a large and long airway 1 with a cross-sectional area of 160mm 2 , the total length of airway 1 is 450mm. When produced by the existing injection molding process, it is easy to Figure 4 There is a large difference in wall thickness 2 between the middle airway and the product appearance surface, forming a bright mark defect.

[0021] The mold for producing the product can adopt the technical scheme disclosed in the Chinese patent CNCN104908258A. The movable mold is provided with a product forming cavity and an overflow groove, and the overflow groove communicates with the product forming cavity and the communicating position is located at the product air passage. An air needle is set on the movable mold and the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com