Silencing structure for power plant water cooling tower

A technology of water cooling towers and cooling towers, which is applied to water shower coolers, sound-generating devices, instruments, etc., and can solve problems such as unguaranteed sound-absorbing effects, unreasonable sound-absorbing structures of metal walls, and obstructed ventilation effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

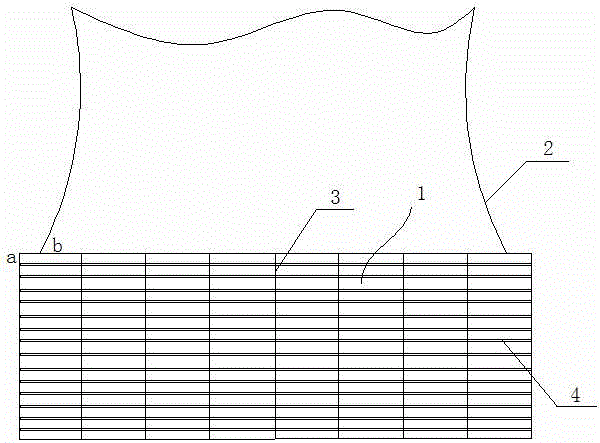

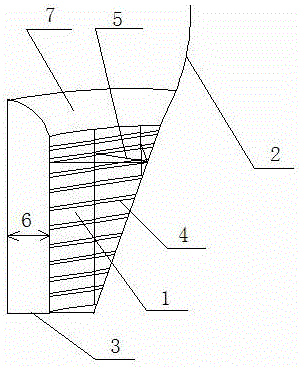

[0017] Such as figure 1 As shown, a sound-absorbing structure for a water cooling tower in a power plant is composed of several sound-absorbing units 1 connected around the bottom of the water cooling tower 2, and a fixed rod 5 is arranged between each sound-absorbing unit 1 and the water cooling tower 2; The silencing unit 1 is composed of a silencing unit frame 3 and a number of silencing sheets 4 with fixed intervals arranged in the frame, wherein the silencing sheets 4 are arranged obliquely, and the side facing the cooling tower 2 is lower than the opposite side; two adjacent The section between the sound-absorbing sheets is a rectangular gap, and the rectangular gap setting follows the following formula: D=2 , where a is the height of the gap, b is the length of the gap, D is the equivalent diameter of the rectangle of the gap, the units of a, b, and D are meters, and 0.01<ab<2.1, 0.11<D<1.64.

[0018] The height of the silencing unit 1 is lower than the height of the ...

Embodiment 2

[0023] The sound-absorbing sheet 4 in the sound-absorbing unit 1 is movably connected with the frame body 3, and the sound-absorbing sheet is rotated by controlling the movable connection point. The gap forms an insulating and sound-absorbing layer.

[0024] This is a special case. In severe cold areas, due to the low temperature, the cooling tower does not require high ventilation, but heat preservation and noise reduction. The adjacent sound-absorbing plates are connected to each other to form a windshield, and the bottom of the cooling tower is surrounded by a relatively closed space, so that the hot water coming down will not freeze easily, and the circulating water pump can pump the water away for circulation.

[0025] The present invention first considers that the root of the noise is the sound of water splashing, instead of processing all the sound frequency bands according to the existing technology, after spectrum analysis, the inventor found that it only needs to pro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap