Welded welding seam detection device

A welding seam detection and signal receiving device technology, applied in the field of detection devices, can solve the problems of rising unqualified product rate, decreasing work efficiency, affecting processing quality, etc., so as to improve work efficiency, avoid human eye fatigue, and avoid naked eye observation. the effect of the error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

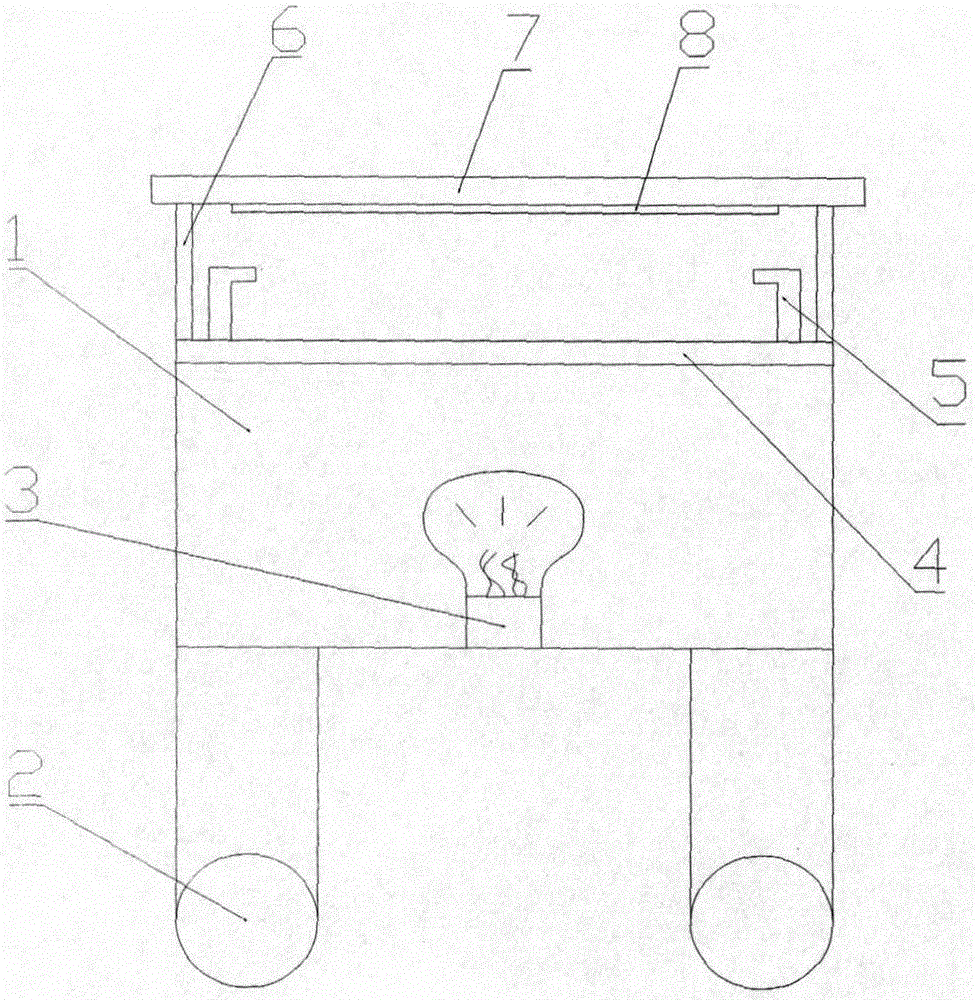

[0015] Such as figure 1 As shown, the invention discloses a welding seam detection device, which includes a detection platform and a signal receiving device arranged on the upper end of the detection platform.

[0016] The testing platform includes a testing platform body 1, a tempered glass 4 arranged on the testing platform body 1, and a searchlight 3 inside the testing platform body 1; A number of rollers 2 are provided, and a pair of inverted L-shaped baffles 5 are arranged symmetrically on the upper end surface of the detection table body 1 .

[0017] The signal receiving device includes a mounting plate 7 and a light source signal sensor 8 arranged on the lower part of the mounting plate 7; the mounting plate 7 is erected on a pair of supporting columns 6, and the supporting columns 6 and a pair of L-shaped baffles 5 are arranged on the detection platform body 1, the light source signal sensor 8 is evenly arranged on the lower end of the mounting plate 7.

[0018] When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com