Inclined wide-narrow row pot seedling transplantation mechanism

A wide-narrow-row, oblique-type technology, applied in the field of agricultural machinery, can solve the problems of affecting the effect of transplanting operations, small gearbox space, unstable movement, etc., and achieve the effects of good transplanting operation quality, small swing and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

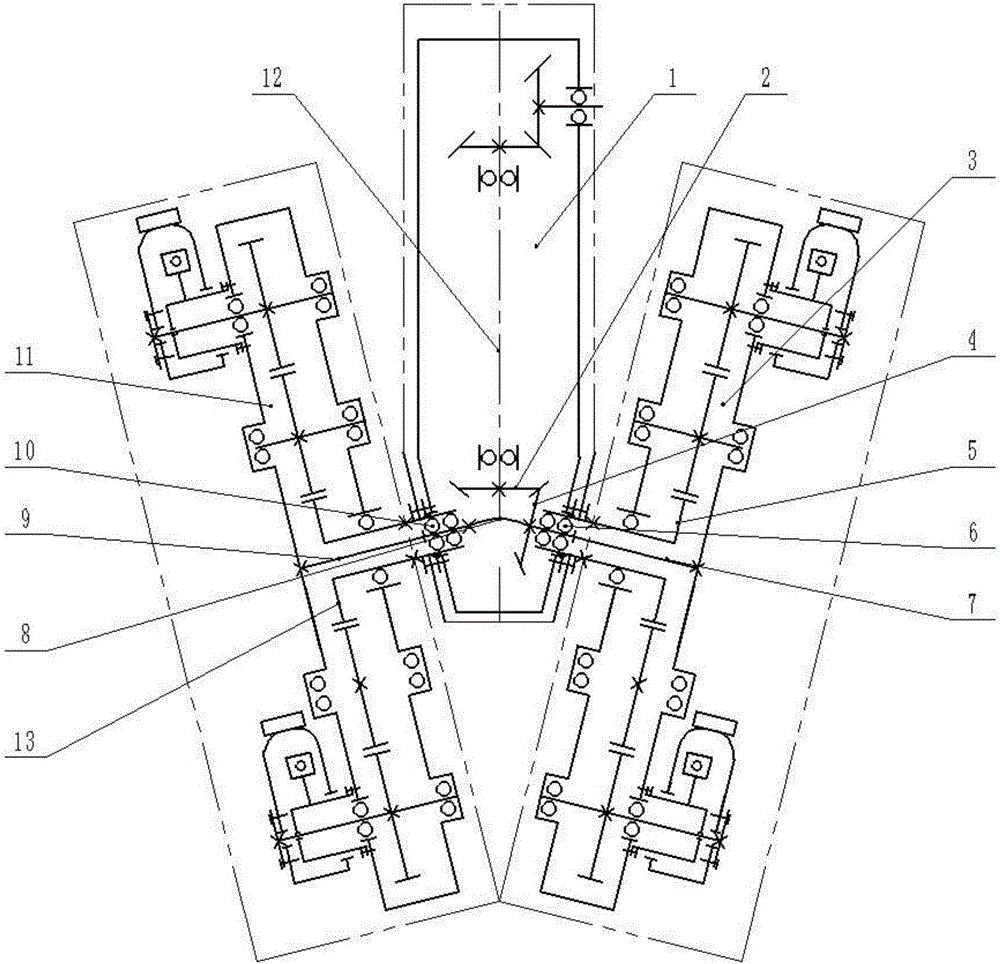

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. An oblique wide and narrow row seedling transplanting mechanism includes a power transmission box 1, a left splitting mechanism 11 and a right splitting mechanism 3, and a left power output shaft 9 and a right power output shaft 9 are relatively equipped on the left and right sides of the power transmission box 1. The power take-off shaft 7, the left and right power take-off shafts 9 and 7 axis centerlines are symmetrically arranged in a downward slope relative to the horizontal plane, and are fixedly installed on the right power take-off shaft 7 or on the left power take-off shaft 9 Bevel gear 4, the driving bevel gear 4 meshes with the driving bevel gear 2 on the main transmission shaft 12 in the power transmission box 1, and the left split-insertion mechanism 11 and the right split-insertion mechanism 3 are connected with the left power output shaft 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com