Carrier pigeon remote control automatic feeder

A remote controller and automatic feeding technology, which is applied in applications, poultry farming, animal husbandry, etc., can solve the problems that the feeding time and feeding amount cannot be changed at any time, and the feeder does not have the function of remote feeding, so as to achieve room for improvement The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

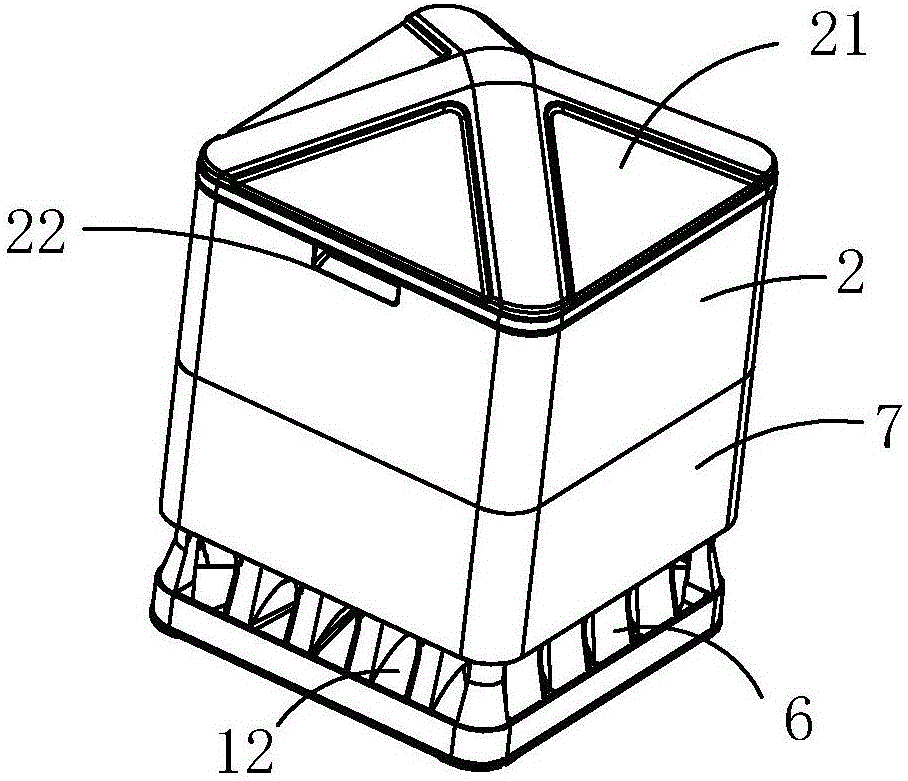

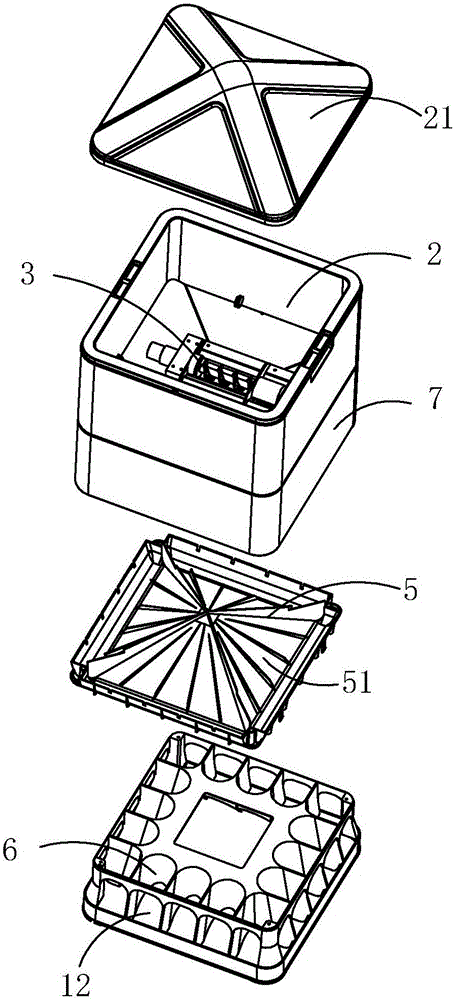

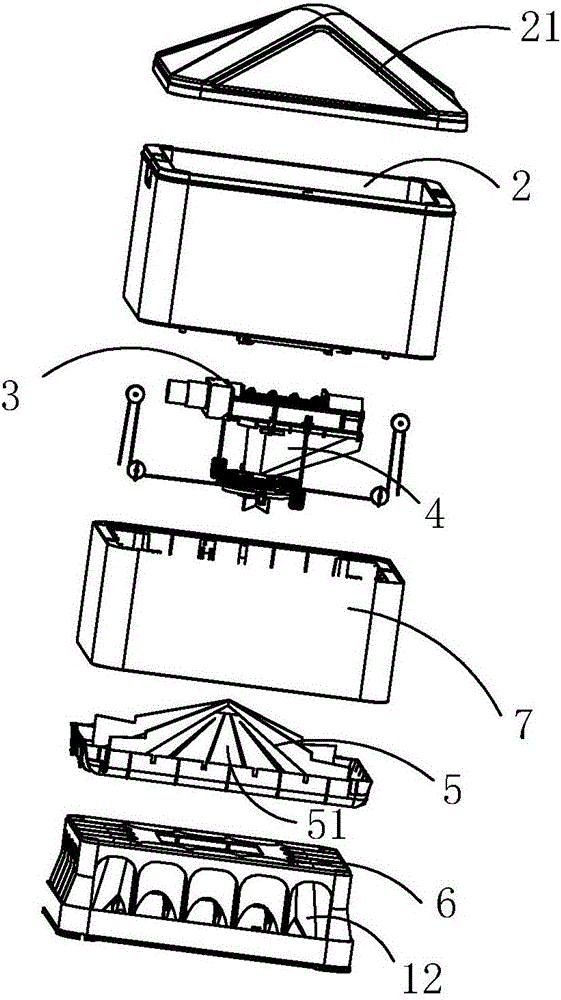

[0020] Please also refer to Figure 1 to Figure 4 , The pigeon remote control automatic feeder of the present invention includes a remote controller 1, a pigeon grain storage, a screw conveyor 3, a pigeon grain distribution pipe 4, a pigeon grain guide plate 5 and a feeding area 6. The program is set in advance at the remote controller 1 to set the opening and closing time of the automatic control screw conveyor 3, thereby realizing regular and quantitative feeding of pigeons. By connecting the remote controller 1 to the remote control terminal 11 through the network, the screw conveyor 3 is turned on and off instantly through the remote control terminal 11, so as to realize feeding the pigeons through the remote control terminal 11 without going to the dovecote for manual feeding. Or it is also possible to remotely modify the program of the remote controller 1 by the remote control terminal 11, so as to reset the opening and closing time of the screw conveyor 3, so as to real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com