Cooking device and primary-frying and blanching system thereof

A technology for cooking equipment and boiling water, which is applied in the field of cooking equipment, can solve the problems of complex structure and huge volume of a lubricating oil system, and achieves the effects of simple and compact structure, simplified structure and improved reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

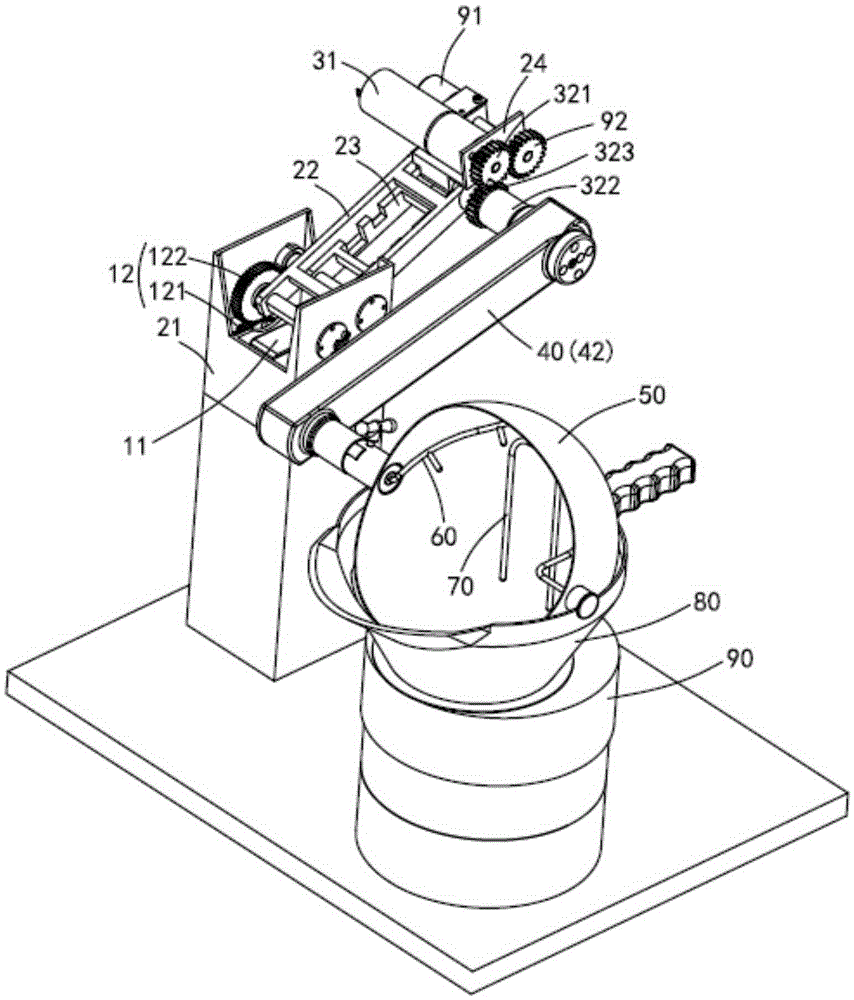

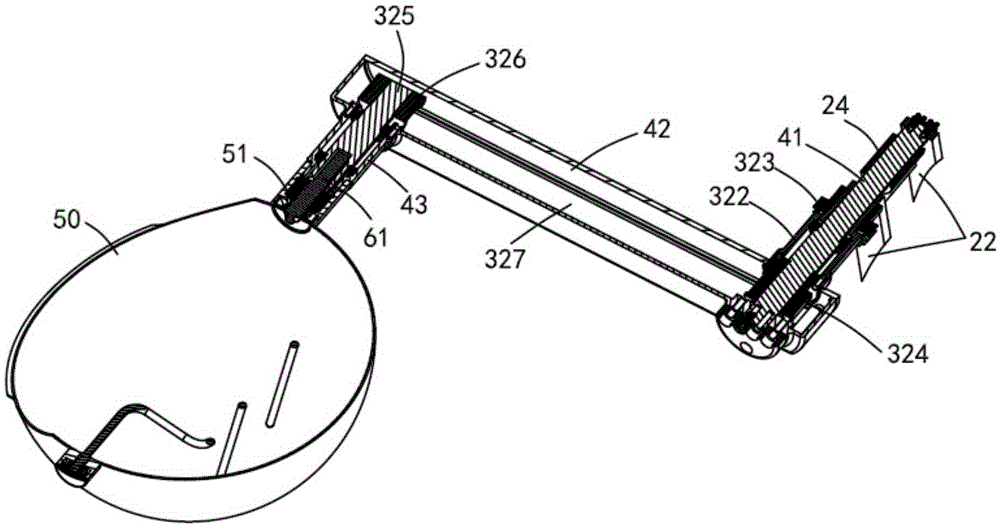

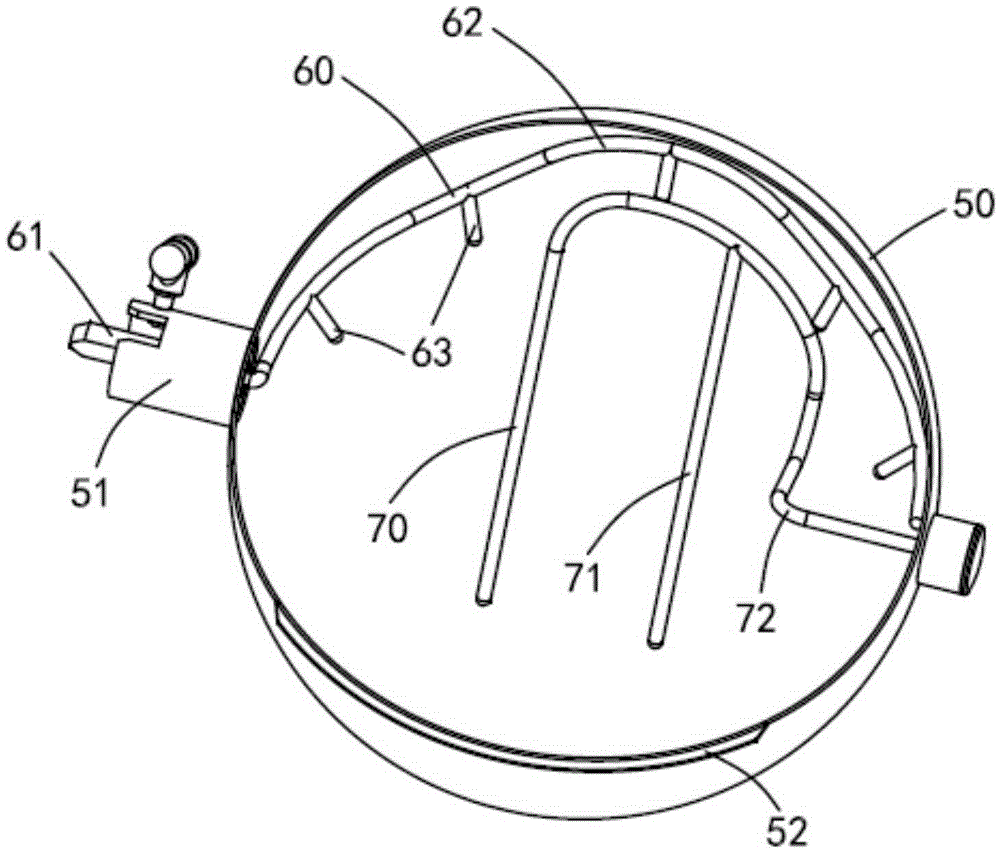

[0033] figure 1 It is a structural schematic diagram of an embodiment of the lubricating oil blanching system of the present invention, figure 2 The connecting mechanism and stirring transmission mechanism in the lubricating oil blanching system are shown. Such as figure 1 and 2 As shown, the lubricating oil blanching system of this embodiment includes: a first motor 11 (pan driving motor), a first gear transmission mechanism 12; a frame 21, a driving link member 22, and a driven link member 23 , connecting rod member 24; second motor 31 (stirring drive motor), stirring transmission mechanism 32; connecting mechanism 40; lubricating oil blanching pot 50; stirring mechanism 60; A heating device 90 for heating the heating medium pan 80, wherein:

[0034] The first motor 11 is arranged on the frame 21, the first gear transmission mechanism 12 includes a first driving gear 121 and a first driven gear 122 meshing with each other, the first driving gear 121 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com