A treatment device and method for aluminum phosphide reaction tail gas

A technology of aluminum phosphide and tail gas, which is applied in the direction of chemical instruments and methods, separation methods, phosphorus compounds, etc., can solve problems such as poor effect, smoke and dust, smoke emission, phosphorus exceeding the standard, etc., and achieve good economic and environmental benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

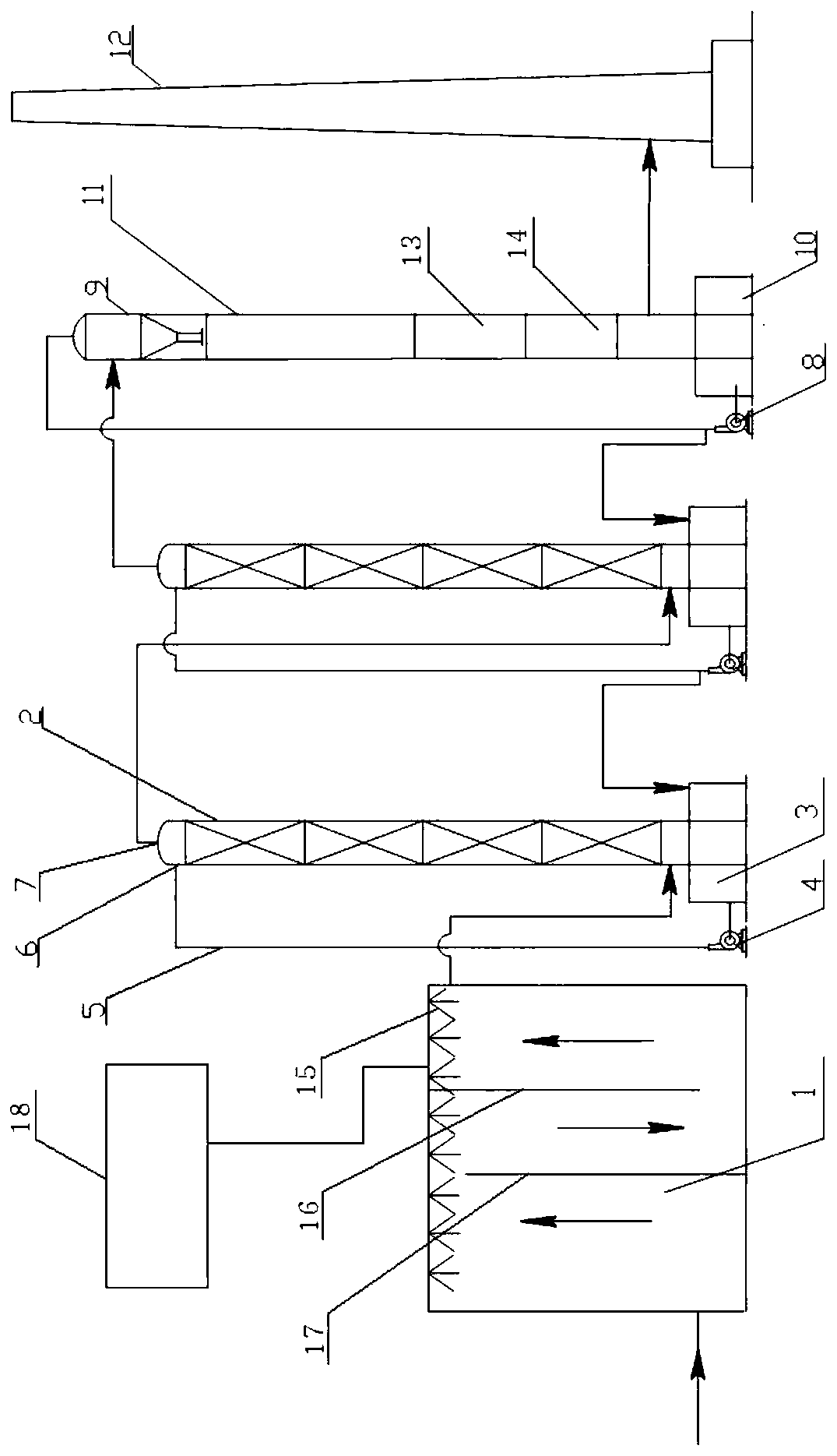

[0021] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

[0022] refer to figure 1 , a treatment device for aluminum phosphide reaction tail gas, the device includes a settling cooling chamber 1, a spray absorption tower 11 and several packed absorption towers 2; the settling cooling chamber 1 is provided with a cooling chamber tail gas outlet and a spraying device 15 , the spray device 15 is arranged on the top of the settling cooling chamber 1; the top of the packed absorption tower 2 is provided with a distributor, a packed tower lye inlet 6 and a packed tower tail gas outlet 7, and the bottom is provided with a packed tower tail gas inlet 1. The bottom is provided with a packed tower lye storage tank 3 with a packed tower lye output port, and a packed tower lye pipe connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com