Garbage crushing device capable of realizing automatic loading degassing

A garbage crushing and automatic feeding technology, which is applied in the direction of gas treatment, grain processing, chemical instruments and methods, etc., can solve the problems of unsmooth discharge and poor crushing effect, and achieve high work efficiency and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

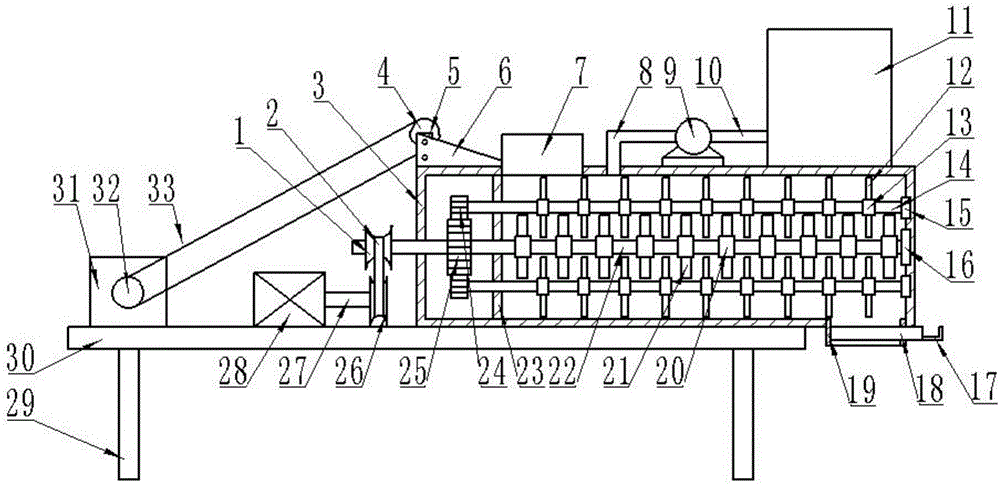

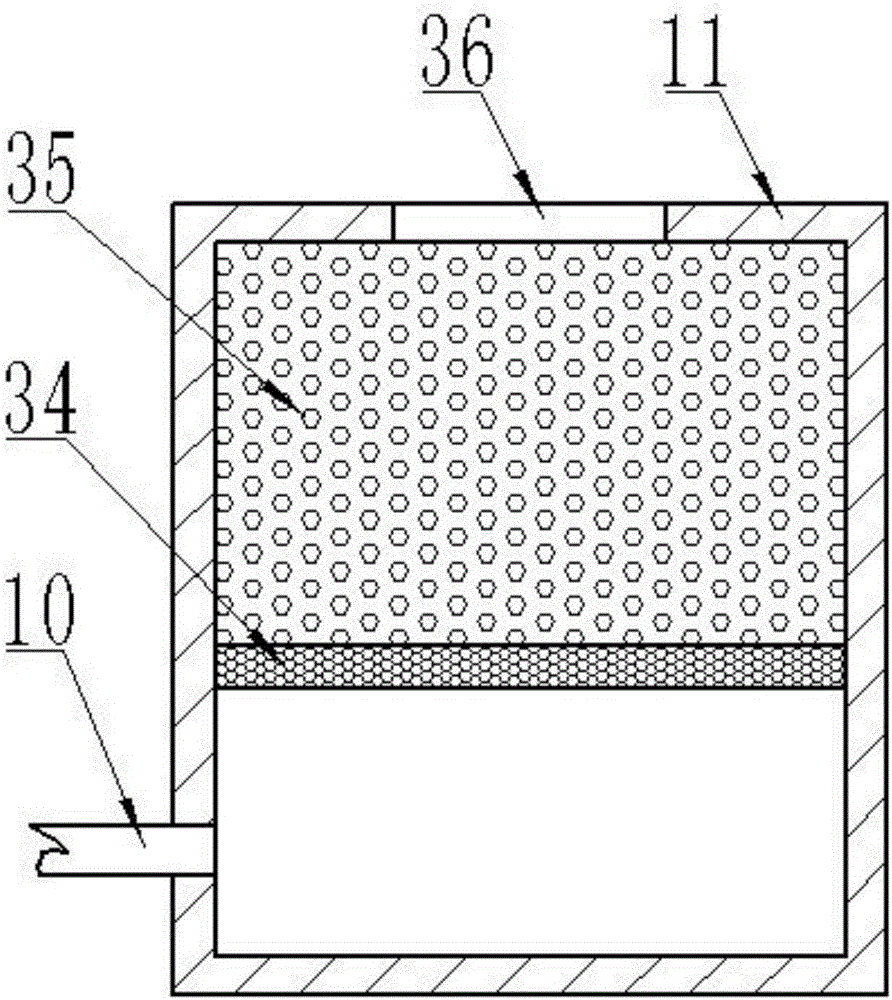

[0019] see Figure 1-2 , an automatic feeding and degassing garbage crushing device, including a feeding device, a crushing device and a degassing device; the feeding device includes a second rotating wheel 4, a second rotating wheel fixing frame 5, a blanking plate 6, A motor 31, a first rotating wheel 32 and a conveyor belt 33; the first motor 31 is fixedly arranged on the left side of the base 30; the first rotating wheel 32 is fixedly arranged on the first motor 31; Two rotating wheel fixed mounts 5 are fixedly arranged on the upper left side of the crushing box 3; The belt 33 is connected; the blanking plate 6 is fixedly arranged on the second rotating wheel fixed frame 5 by screws, and is communicated with the feeding cylinder 7; the first motor 31 is started to drive the conveyor belt 33 to rotate, and the garbage is transported in the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com