Automatic washing equipment of dish-shaped and bowl-shaped objects and control method of automatic washing equipment

A self-cleaning, dish-shaped technology, applied in the direction of cleaning equipment, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem of greasy stains that are difficult to be cleaned, and achieve the effect of ensuring hygiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

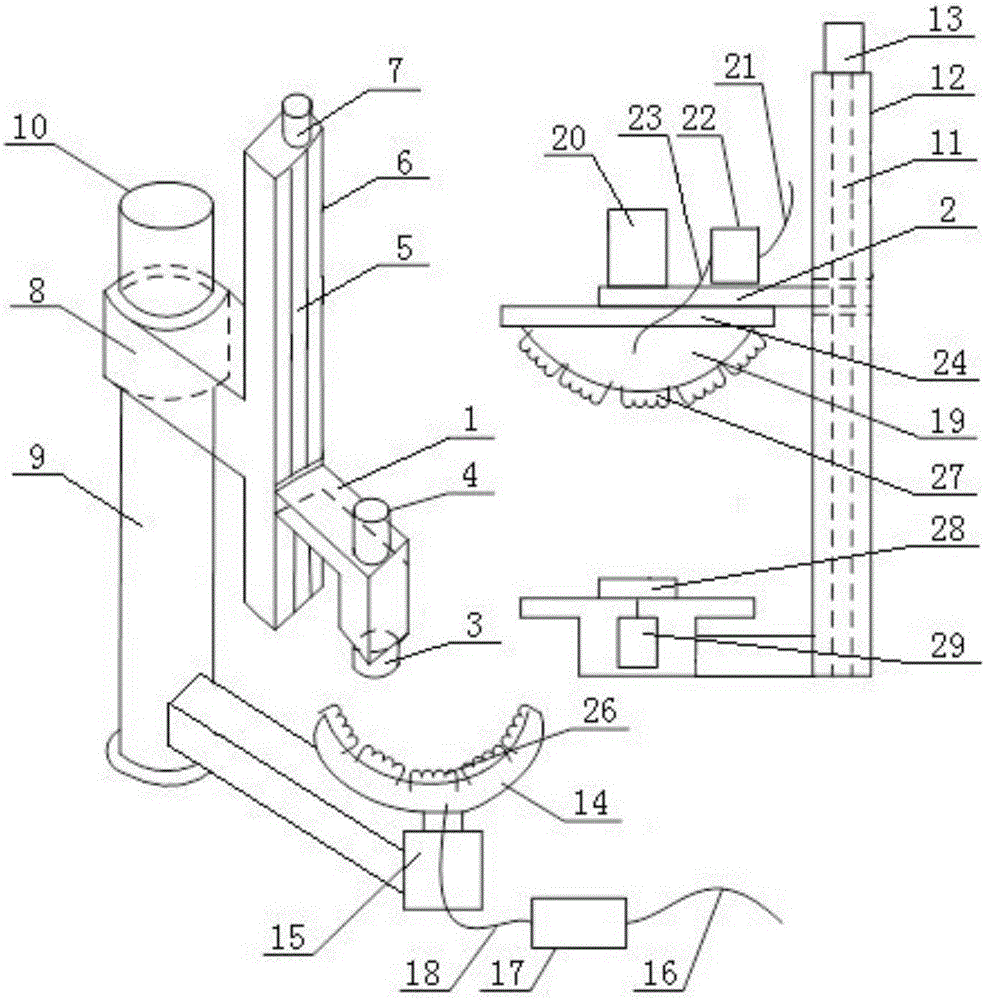

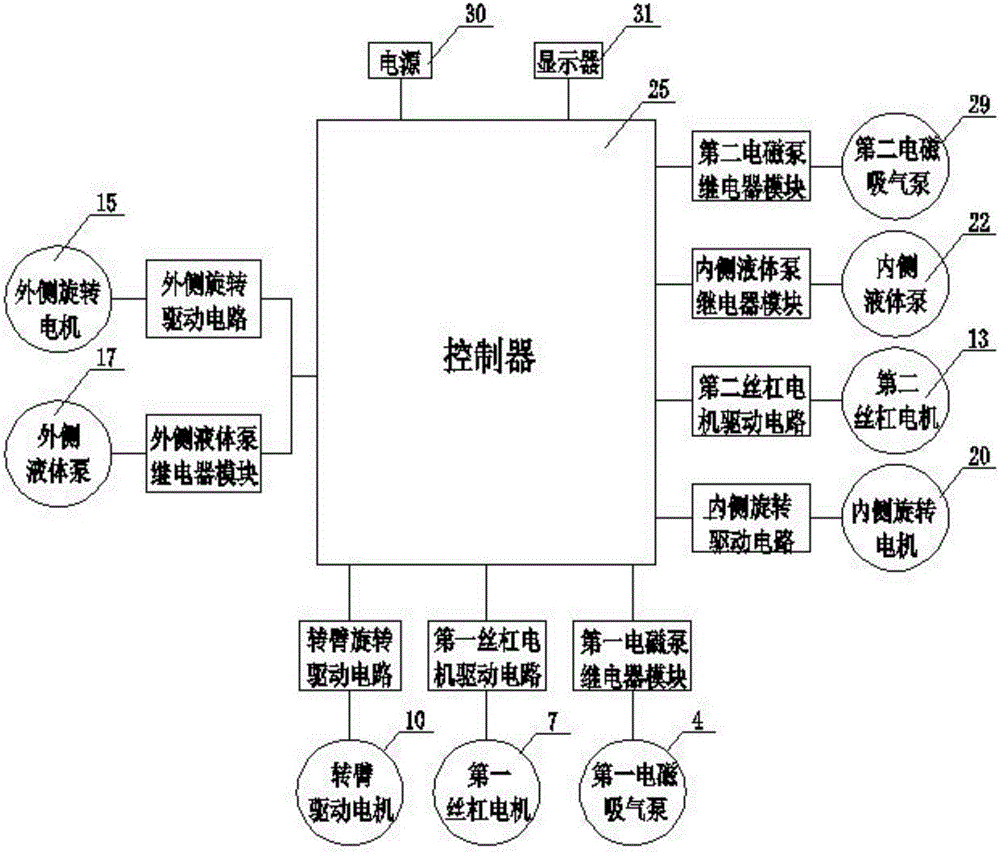

[0035] refer to figure 1 , the dish-shaped bowl-shaped object automatic cleaning equipment, including picking up and fixing hand 1, inside cleaning hand 2, inside cleaning device, outside cleaning device, the bottom of described picking up and fixing hand 1 is provided with first pneumatic suction cup 3, and picking up and fixing hand 1 The top of the top is provided with the first electromagnetic suction pump 4 that links to each other with the first pneumatic sucker 3, picks up the rear end of fixed hand 1 and is fixed on the first lead screw 5, and the first lead screw 5 is vertically arranged on the first fixed frame 6 Inside, and driven by the first lead screw motor 7 arranged on the first fixed frame 6, the first fixed frame 6 is arranged on the supporting column 9 by rotating the rotating arm 8 arranged horizontally, and the supporting column 9 is provided with the rotating arm driving The motor 10, the outer cleaner includes an outer cleaning part 14, an outer rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com